Power Inverters: What Are They & How Do They Work?

Jul 23, 2025 · An inverter is a device that is used to convert Direct current to Alternating Current. However the output is not a sine wave. It can be square

An advanced guide to Understanding DC to AC inverters

Apr 4, 2024 · Various electronics have an input of either 12, 24, or 28 DC voltage, and in order to use appliances with an AC output voltage, you must have a power inverter. Among the more

What Is An Inverter? | Definition, Types, Uses,

Jan 25, 2025 · An inverter is a vital electrical device that converts direct current (DC) into alternating current (AC), which is used to power many household

Inverter Voltage Calculator, Formula, Inverter Voltage

3 days ago · Inverter Voltage Formula: Inverter voltage (VI) is an essential concept in electrical engineering, particularly in the design and operation of power electronics systems. It describes

High Voltage Solar Inverter DC-AC Kit

Sep 3, 2014 · This document describes the implementation of the inverter kit that used as a DC-AC part of the High Voltage Solar Inverter DC-AC Kit. The kit has a nominal input of 400-V

TOPIC: Power inverters and converters. Basic Electricity

Oct 8, 2023 · The input voltage, output voltage and frequency, and overall power handling depend on the design of the specific device or circuitry. The inverter does not produce any power; the

Understanding Inverter Input And Output: What

3 days ago · The inverter output is the electrical power generated by the inverter from the process of converting the DC input source into alternating current

Introduction to inverters: structure, operating

May 24, 2024 · Discover the basics of inverters - their structure, operating principles, and functions. Explore Junchipower''s expertise in this informative

Working Principle of DC-DC Conversion Circuit

Feb 5, 2021 · In conclusion, the DC-DC converter, as a core circuit for achieving the MPPT function, has been widely applied to solar on-grid inverters, light

Technical Note: Oversizing of SolarEdge Inverters

Oct 30, 2023 · The inverter limits or clips the power output when the actual produced DC power is higher than the inverter''s allowed maximum output. This results in a loss of energy.

6 FAQs about [Is the output of the inverter DC ]

What is inverter output?

The inverter output is the electrical power generated by the inverter from the process of converting the DC input source into alternating current (AC).

What is a DC inverter?

Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for household and industrial applications. Working Principle: Inverters use power electronics switches to mimic the AC current’s changing direction, providing stable AC output from a DC source.

How does an inverter work?

The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control. The inverter outputs a pulsed voltage, and the pulses are smoothed by the motor coil so that a sine wave current flows to the motor to control the speed and torque of the motor.

Do inverters convert DC to AC?

While DC power is common in small gadgets, most household equipment uses AC power, so we need efficient conversion from DC to AC. An inverter is a static device that converts one form of electrical power into another but cannot generate electrical power.

Does a power inverter produce power?

The power inverter, and also called inverter is an electronic circuit that converts DC electricity to AC electricity. Actually, the inverter does not produce power, but if there is a DC source, and it just converts it to AC power. What is the power inverter typical inputs?

What is the output power capacity of an inverter?

Output Power Capacity: The inverter output power capacity is separated into two, which are. Continuous power: This is stable power supplied continuously without interruption. Peak power: the maximum power that can be supplied by the inverter in a short time.

Learn More

Industrial & Commercial Energy Storage Market Growth

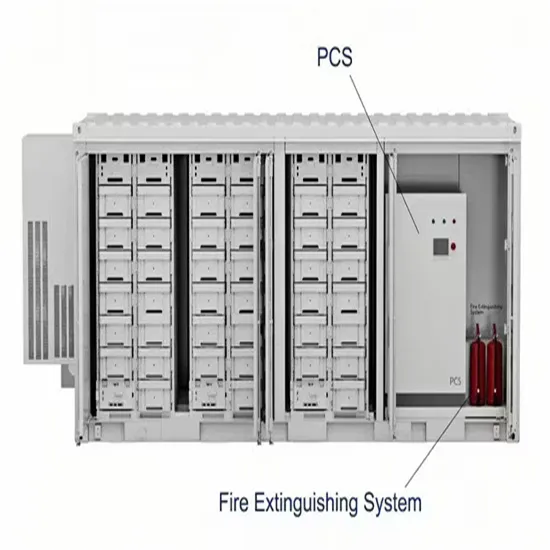

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.