Understanding Split Phase Inverters: A Complete Guide

Mar 17, 2025 · Split Phase Vs Three Phase Inverters Three Phase Inverters: Output: Produces three AC outputs that are 120 degrees out of phase with each other. Common Use: commonly

What is Three Phase Inverter and How Does It Work

Aug 1, 2025 · Three-phase output provides smoother and more consistent power delivery. This is crucial for sensitive electronics and high-precision machinery that require clean, balanced

What is a Three-Phase Inverter? | inverter

Sep 17, 2024 · In modern power systems, three-phase inverters, as a key power conversion device, play a vital role. Whether in industry, agriculture, or home, three-phase inverters

How to do output power measurement of a three phase inverter

Dec 24, 2024 · Here are the details: I am trying to measure output power of a three phase inverter using "Power Measurement (Three-Phase)" block. For my project it is very important to

Aalborg Universitet Step by Step Design of a High Order

tly affected by the output line to line voltage. Hence, this paper proposes a new method o analyze the inverter output current harmonics by using the equivalent phase voltage of the three phase

Single-Phase & Three-Phase Inverters: Function and Operation

Jun 15, 2024 · A 3-phase output can be obtained by adding only two more switches to the four needed for a single-phase inverter, giving the typical power-circuit configuration illustrated below:

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · Features Three-phase inverter power stage suited for 200-480 VAC powered drives with output current rating up to 14 Arms Reinforced isolated gate driver with opto

GoodWe Unbalanced Power Supply Solution (English)---2

Dec 23, 2022 · The on-grid output of GoodWe ET series can realize 100% unbalanced phase-level output, which means each phase can output power from 0W up to 1/3 of inverter nominal

Three Phase Inverter Circuit Diagram Explained

Use a three-phase inverter circuit to convert DC power into a balanced three-phase AC output suitable for industrial motors and renewable energy systems. The core components include six

6 FAQs about [Power inverter three-phase output]

What is a three-phase inverter?

In power electronics, a three-phase inverter is an essential device to convert DC (Direct Current) electricity into AC (Alternating Current) with three distinct phases. These inverters are widely utilized in industrial, commercial, and renewable energy applications where efficient power distribution and reliability are paramount.

What is a three phase bridge inverter?

A three phase bridge inverter is a device which converts DC power input into three phase AC output. Like single phase inverter, it draws DC supply from a battery or more commonly from a rectifier. A basic three phase inverter is a six step bridge inverter. It uses a minimum of 6 thyristors.

How many conduction modes are there in a 3 phase inverter?

However in three-phase inverters , this voltage is distributed across three phases to create a balanced three-phase AC output . There are two primary conduction modes in both single-phase and three-phase inverters i.e.. 120-degree conduction mode and the 180-degree conduction mode.

Which industries use three-phase inverters?

Industries such as manufacturing, data centers, and large-scale commercial operations commonly use three-phase inverters to ensure stable and efficient power management. Moreover, they play a critical role in renewable energy systems, particularly in solar power installations. Three-phase inverters are employed in various sectors, including:

How many thyristors are in a 3 phase inverter?

A basic three phase inverter is a six step bridge inverter. It uses a minimum of 6 thyristors. In inverter terminology, a step is defined as a change in the firing from one thyristor to the next thyristor in a proper sequence. For getting one cycle of 360°, each step is of 60° interval.

What is the difference between a half-phase and a three-phase inverter?

In a three-phase inverter , the pole voltage , which represents the voltage applied to the load , is equivalent to the pole voltage in a half-phase inverter used in single-phase applications . However in three-phase inverters , this voltage is distributed across three phases to create a balanced three-phase AC output .

Learn More

- Iraq three-phase power frequency inverter

- Photovoltaic inverter adjusts output power

- Three-phase inverter floating power supply

- 24V4000W inverter output power

- Inverter output constant power

- Single-phase inverter output power design

- Italy Milan power frequency isolation 200kw inverter

- 10kv three-phase photovoltaic inverter

- Solar power inverter silicon carbide

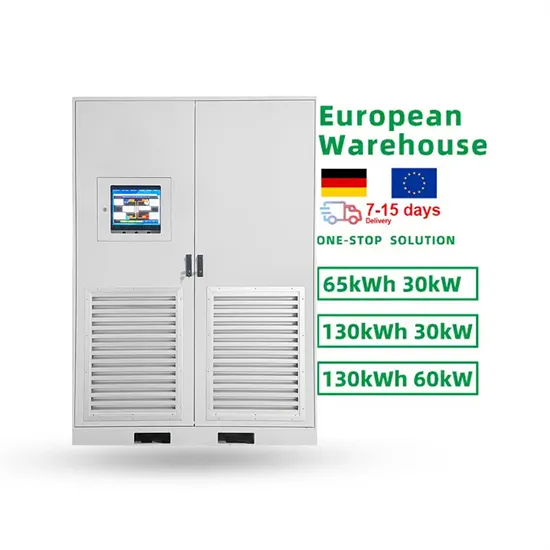

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.