3three-level-PWM_FINAL_DOUBLE_CULOMN_TIFF

Sep 4, 2016 · Abstract–This paper presents a topology of a single-phase floating full-bridge three-level PWM power inverter suitable for high-voltage / high-power DC-AC conversion. High

How to detect and fix a ''Floating Neutral''

Aug 17, 2025 · Floating Neutral problem: In 3-phase supplied in Australia (and elsewhere), the three-phase supply is in ''Star connection, with the neutral at the star point, and the MEN link to

3three-level-PWM_FINAL_DOUBLE_CULOMN_TIFF

Oct 6, 2023 · Abstract–This paper presents a topology of a single-phase floating full-bridge three-level PWM power inverter suitable for high-voltage / high-power DC-AC conversion. High

62.5W auxiliary power supply for three-phase power

Jan 18, 2024 · Scope and purpose This document demonstrates the solution for high input voltage DC link 62.5 W auxiliary power supply designs using Infineon''s 1700 V CoolSiCTM MOSFET

11-kW, Bidirectional Three-Phase Three-Level (T-type)

Feb 20, 2025 · Description This reference design provides an overview on how to implement a bidirectional three-level, three-phase, SiC-based active front end (AFE) inverter and power

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · Three-phase inverter reference design for 200–480 VAC drives with opto-emulated input gate drivers Description This reference design realizes a reinforced isolated three-phase

Three-Phase Inverter Reference Design Using Gate

Dec 6, 2017 · Description This reference design reduces system cost and enables a compact design for a reinforced, isolated, 10-kW, three-phase inverter. A lower system cost and

Impact of Floating Neutral in Power Distribution

Oct 24, 2024 · Here we observe that Neutral Floating condition does not impact on 3 Phase Load but It impacts only 1 Phase Load only How to Eliminate Neutral Floating: There are Some

Isolated IGBT Gate-Drive Power Supply Reference Design

Sep 27, 2018 · Three-phase inverters convert the DC bus voltage to three-phase AC voltage with adjustable magnitude and frequency depending on the application. The three-phase inverters

Compact, Non-Isolated, Three-Phase Inverter Ref Design

Apr 19, 2020 · Three-phase inverter power stages are the fundamental building blocks in industrial motor drive applications like pumps, compressors, robotics, machine tools, and CNC

Wide-Input Isolated IGBT Gate-Drive Fly-Buck Power

Jan 5, 2016 · IGBTs are used in three phase inverters for variable-frequency drives to control the speed of AC motors. This reference design uses a Fly-Buck topology and is intended to

A New Three Phase 5-Level Converter by Cascading a

Apr 17, 2014 · To overcome the issues, a new three-phase, five-level inverter topology with a single-dc source is presented. The proposed topology is obtained by cascading a three-level

Floating Power Supply Based on Bootstrap Operation for

This paper presents a survey of floating power supply based on bootstrap operation for three-level voltage-source inverters. The floating power supply for upper switches is achieved by the

62.5W auxiliary power supply for three-phase power

Jan 18, 2024 · The reference board is intended to support customers designing an auxiliary power supply for three-phase converters using the Infineon 1700 V CoolSiCTM MOSFET. Potential

A Multi-Level Converter with a Floating Bridge for Open

Jul 4, 2023 · Among the cascade converters, dual two-level inverter topology has received attention due to the simplicity of the power stage and the arrangement''s fault tolerant capacity

1.3kW GaN Totem Pole PFC and Motor Inverter

Jul 23, 2025 · Description This reference design is a 1.3kW totem pole power factor correction (PFC) and motor inverter for major appliances and similar products. The design illustrates a

Lecture 23: Three-Phase Inverters

Feb 24, 2025 · Lecture 23 - 3-phase inverters Prof. David Perreault Consider implementation of an inverter for 3-phase using three single-phase inverters (e.g. full-bridge or half-bridge), one

A Novel Step Down Auxiliary Power Supply employed in

Apr 25, 2005 · In this paper a novel power supply solution is proposed. The topology of the proposed auxiliary power supply is based on a buck converter with floating control circuit. The

10-kW, Bidirectional Three-Phase Three-Level (T-type)

Sep 27, 2023 · The DelfinoTM TMS320F2837xD is a powerful 32-bit floating-point microcontroller unit (MCU) designed for advanced closed-loop control applications such as industrial drives

Electrolytic Capacitor-Less Dual Inverter-Fed IPMSM for

Oct 1, 2019 · This paper proposes a suppression method of the motor torque pulsation in electrolytic capacitor-less single-phase to three-phase power converter. The proposed system

What is Three Phase Inverter?

Nov 6, 2024 · Enhanced Power Density: Three-phase inverters enable the supply of balanced amperage with the smaller wires, maximizing the overall power density in the distribution

Bootstrap power supply for three-level neutral-point-clamped voltage

Jun 5, 2012 · Abstract: This paper presents a survey of floating power supplies based on bootstrap operation for three-level neutral-point-clamped (NPC) voltage source inverters (VSI).

Floating Power Supply Based on Bootstrap Operation for Three

This paper presents a survey of floating power supply based on bootstrap operation for three-level voltage-source inverters. The floating power supply for upper switches is achieved by the

10-kW, Bidirectional Three-Phase Three-Level (T-type)

Feb 20, 2025 · The DelfinoTM TMS320F2837xD is a powerful 32-bit floating-point microcontroller unit (MCU) designed for advanced closed-loop control applications such as industrial drives

Hybrid Inverter

Apr 25, 2023 · 1 Status, Power, Frequency. 2 L1&L2: Voltage for each Phase CT1&CT2: External Current Sensor Power LD1&LD2: Internal Current Sensor Power. 3 BUY: Energy from Grid to

Small Form-Factor Reinforced Isolated IGBT Gate Drive

Jun 23, 2017 · This compact reference design controls IGBTs in 3-phase inverters, such as AC drives, uninterruptible power supplies (UPS) and solar inverters. The design uses a reinforced

Wide-Input Isolated IGBT Gate-Drive Fly-Buck Power

Jan 5, 2016 · Wide-Input Isolated IGBT Gate-Drive Fly-BuckTM Power Supply for Three-Phase Inverters TI Designs TI Designs provide the foundation that you need including methodology,

6 FAQs about [Three-phase inverter floating power supply]

What is a reference design for a 3 phase inverter?

This reference design reduces system cost and enables a compact design for a reinforced, isolated, 10-kW, three-phase inverter. A lower system cost and compact form factor is achieved by using a dual gate driver in a single package and bootstrap configuration to generate floating voltages for the gate drive power supply.

What is a three-phase inverter used for?

Three-phase inverters function as variable-frequency drives to control the speed of AC motors and for high power applications such as HVDC power transmissions. The typical application of a three-phase inverter using six isolated gate drivers is shown in Figure 1.

How many power switches does a three-phase inverter use?

A three-phase inverter application uses six power switches (IGBTs in this case). To drive these switches, six totally independent gate drivers are required. Also, with a high-voltage operation, it is necessary to have enough isolation between primary and secondary side of the gate driver.

How many gate drivers does a 3 phase inverter use?

The typical application of a three-phase inverter using six isolated gate drivers is shown in Figure 1. Note that each phase uses a high-side and a low-side IGBT switch to apply positive and negative high-voltage DC pulses to the motor coils in an alternating mode.

What are three-phase inverter power stages?

Three-phase inverter power stages are the fundamental building blocks in industrial motor drive applications like pumps, compressors, robotics, machine tools, and CNC machines. The inverter converts a DC voltage into a variable frequency and power AC output to drive the motor. The generic motor control blocks are shown in Figure 1.

How does a 3 phase inverter work?

However, most 3-phase loads are connected in wye or delta, placing constraints on the instantaneous voltages that can be applied to each branch of the load. For the wye connection, all the “negative” terminals of the inverter outputs are tied together, and for the detla connection, the inverter output terminals are cascaded in a ring.

Learn More

- How long can the energy storage inverter supply power

- Can the UPS inverter be connected to the power supply to charge the battery

- Which is better lithium battery plus inverter or mobile power supply

- Lithium battery 12v inverter power supply

- High power three-phase pwm inverter

- Method for converting single-phase to three-phase power supply of base station

- How big an inverter should I use for a 60v power supply

- 12v inverter booster power supply

- Three-phase UPS uninterruptible power supply 20kva power supply for 1 hour

Industrial & Commercial Energy Storage Market Growth

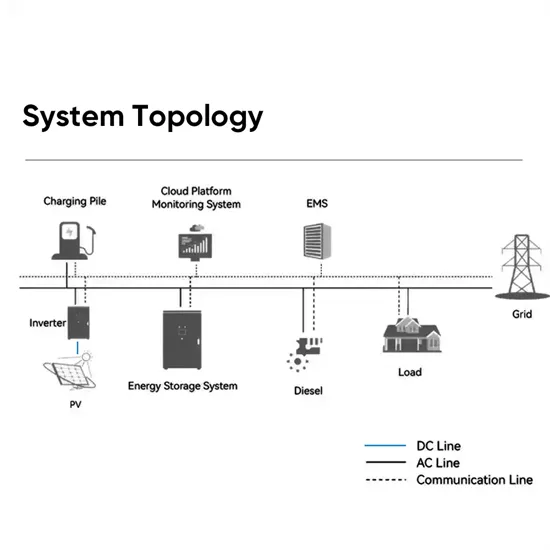

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.