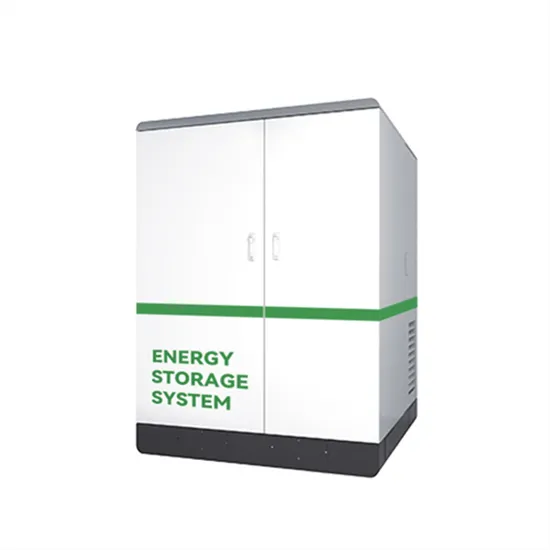

Air-cooled C&I BESS Energy Storage Cabinet | AZE

AZE''s Our air-cooled C&I BESS Energy Storage Cabinet is the perfect solution for your business. With advanced air-cooling technology, scalable design, and smart energy management, our

Battery Cabinet Convection Cooling and CoolCab Fan

Feb 7, 2020 · net Convection Cooling and CoolCab Fan System Challenge: Help reduce the internal battery cabinet temperature taking into consideration the cabinet internal ba. t and the

Top-Rated Cooling Systems for Battery Cabinets

Could your current cooling system handle the 500W/cm² heat flux of next-gen silicon anode batteries? With 83% of new battery installations occurring in tropical regions, the industry must

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

LIQUID COOLING SOLUTIONS For Battery Energy

Aug 3, 2022 · directly connect with the battery system with no need for power conversion. Small footprint: for an easy integration inside the battery cabinets and enclosures. Inverter pump and

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · The common cooling media for BESS are air and liquid. Regardless of whether air or liquid cooling is used, the flow uniformity of the cooling medium will have an effect on the

How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Feb 21, 2025 · 2. Material Selection and Sourcing AZE Systems uses only the highest-quality materials to ensure the durability and reliability of its BESS cabinets. Key materials include:

Liquid Cooling Battery Cabinet: Efficient Solution

To ensure reliability and maximize performance, these systems must operate under optimal conditions, with thermal management being a key factor. A pivotal innovation addressing this

How to design an energy storage cabinet: integration and

Jan 3, 2025 · Efficient heat dissipation design: Lithium batteries and inverters will generate a certain amount of heat during operation, so the energy storage cabinet requires an effective

Liquid Cooling Battery Cabinet: Efficient Solution

Innovations in Battery Cabinet Cooling Technology The sophistication of modern Battery Cabinet Cooling Technology is a testament to precision engineering. These are not simply add-on

Engineering Design of Liquid Cooling Systems in

Jul 3, 2025 · A well-designed liquid cooling system starts with a closed-loop architecture where coolant flows through channels embedded in or adjacent to

Complete Guide for Battery Enclosure

May 29, 2024 · Insulation system – insulation is also a safety measure a battery cabinet should have. Grille – it allows for free air flow thereby ensuring efficient

Ventilation and Thermal Management of Stationary

Jan 10, 2023 · The purpose of the document is to build a bridge between the battery system designer and ventilation system designer. As such, it provides information on battery

Liquid Cooling Battery Cabinet by Hicorenergy

The Future of Energy Storage: The Role of Advanced Cooling As the demand for high-capacity energy storage continues to surge across commercial and industrial sectors, the technology

Cabinet Cooling: A Key Aspect in Energy Storage Systems

Apr 29, 2025 · There are several cooling methods commonly used for cabinet cooling in energy storage systems. Each method has its own advantages and disadvantages, and the choice of

Liquid Cooling Battery Cabinet Efficiency & Design

Unlike air cooling, which relies on circulating air to dissipate heat, liquid cooling uses a specialized coolant that flows through pipes or plates integrated within the battery cabinet. This fluid has a

Utility-scale battery energy storage system (BESS)

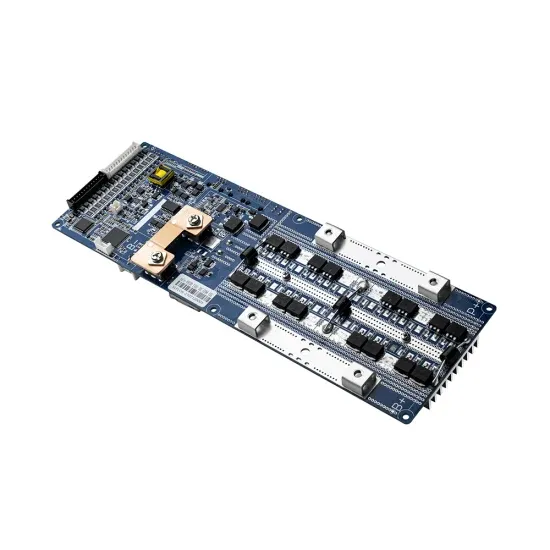

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

LIQUID COOLING SOLUTIONS For Battery Energy

Aug 3, 2022 · For Battery Energy Storage Systems Are you designing or operating networks and systems for the Energy industry? If so, consider building thermal management solutions into

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

The Importance of Advanced Thermal Management Effective temperature control is paramount for the health of any battery energy storage system (BESS). Traditional air cooling methods, while

Passive Cooling Techniques for EV Battery Protection

Mar 11, 2025 · Thermal management system for battery packs, particularly electric vehicle battery packs, that provides improved cooling and heat distribution compared to existing systems.

Energy Storage System Cooling

May 5, 2025 · Thermoelectric cooler assemblies optimize temperature stabilization to ensure sensitive battery back-up systems operate at maximum efficiency — all in a smaller package

6 FAQs about [Battery cabinet cooling system selection ideas]

Why is water cooling important for lithium ion batteries?

bility is crucial for battery performance and durability. Active water cooling is the best thermal management method to improve the battery pack performances, allowing lithium-ion batteries

What temperature should battery cells be kept in a cooling unit?

The cooling unit must ensure the maximum temperature of the battery cells within the container does not exceed the threshold set by the battery manufacturer (such as 45°C or 50°C) at the end of these cycles. Operating battery cells above 35°C accelerates aging, resulting in faster degradation.

What are battery energy storage systems (Bess)?

As the demand for sustainable energy solutions grows, Battery Energy Storage Systems (BESS) have become crucial in managing and storing energy efficiently. This year, most storage integration manufacturers have launched 20-foot, 5MWh BESS container products.

Can a battery energy storage system fit a closed-loop air conditioner?

A leading manufacturer of battery energy storage systems contacted Kooltronic for a thermal management solution to fit its rechargeable power system. Working collaboratively with the manufacturer, Kooltronic engineers modified a closed-loop air conditioner to fit the enclosure, cool the battery compartment, and maximize system reliability.

What are the different types of liquid cooling units?

However, each integrator’s thermal design varies, particularly in the choice of liquid cooling units, which come in different cooling capacities: 45kW, 50kW, and 60kW. Despite using the same 314Ah battery cells, why do these systems differ so significantly in liquid cooling unit selection? Let’s delve into the details.

What is the cooling load of a battery?

Here, the cooling load depends on the difference between the maximum operating temperature of the battery (such as 35°C, 40°C, 45°C, 50°C) and the initial temperature of 25°C (∆T).

Learn More

- How to charge the battery cabinet liquid cooling energy storage solar panels

- Thermal protection of battery cabinet water cooling system

- New energy battery cabinet water cooling connector

- Liquid Cooling Battery Cabinet Production Line

- Yemen Liquid Cooling Energy Storage Battery Cabinet Integration System

- Ouagadougou domestic liquid cooling battery cabinet top ten brands

- UPS battery cabinet placed close to the ground

- ASEAN battery cabinet platform system

- Lithium Battery Site Cabinet Requirements

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.