2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · Each set of 12 battery clusters connects to a bus cabinet, forming a standard 5MWh DC compartment energy storage system. Externally, a 2500kW PCS connects (two

232kWh Liquid Cooling Battery Energy Storage System | GSL Energy

Mar 26, 2025 · GSL Energy has taken another significant step in advancing energy storage solutions by installing a 232kWh liquid cooling battery energy storage system in Dongguan,

Energy, economic and environmental analysis of a combined cooling

Sep 10, 2024 · Huge energy consumption of data centers has become a concern with the demand for greater computing power. Indirect liquid cooling is currently the main cooling method for the

New Energy Storage Battery Technology in Yemen: Powering

As global attention shifts toward renewable energy storage solutions, Yemen stands at a crossroads—and new energy storage battery technology might just hold the key to its

Liquid Cooling: Efficiency in Battery Storage

The solution to this challenge is the advanced Liquid Cooling Battery Cabinet, a technology designed to provide precise and uniform temperature control, ensuring optimal performance

customized large scale liquid cooled energy

6 days ago · Containerized Liquid-cooling Energy Storage System represents the cutting edge in battery storage technology. Featuring liquid-cooling DC battery

Liquid Cooling Energy Storage System

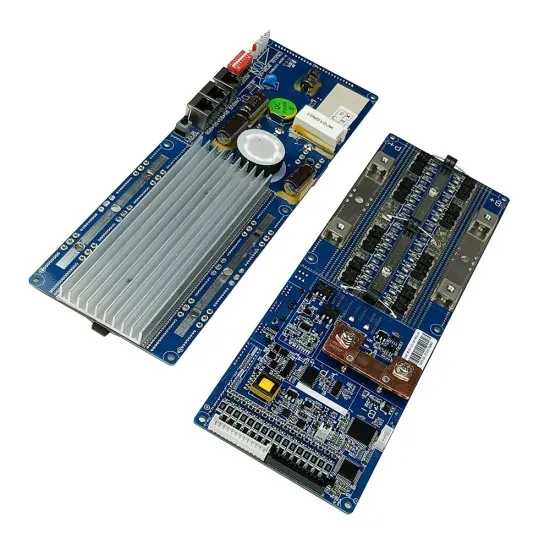

Dec 22, 2023 · The 211kWh Liquid Cooling Energy Storage System Cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS

SHANGHAI ELECNOVA ENERGY STORAGE CO., LTD.

Compared to traditional lead-acid batteries used as backup power solutions, energy storage integrated cabinets offer higher system integration, greater safety at all times, and improved

Battery Storage Cabinets: The Backbone of Safe

Apr 11, 2025 · Battery storage cabinets are more than just enclosures; they are sophisticated systems that play a crucial role in the safety, efficiency, and

Yemen Energy Storage Cabinet Container Customization

Container Energy Storage Solution / Containerized At OE, we provide an end-to-end suite of services for container energy storage solutions, covering the entire lifecycle. This includes

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Liquid Cooling Battery Cabinet: Efficient Solution

Innovations in Battery Cabinet Cooling Technology The sophistication of modern Battery Cabinet Cooling Technology is a testament to precision engineering. These are not simply add-on

Engineering Design of Liquid Cooling Systems in

Jul 3, 2025 · A well-integrated Liquid Cooled Energy Storage Cabinet doesn''t just run cooler—it runs smarter and lasts longer. In practical applications like

Liquid Cooled Battery Energy Storage Systems

Jan 28, 2024 · In the ever-evolving landscape of battery energy storage systems, the quest for efficiency, reliability, and longevity has led to the development of more innovative

Energy Storage System Cooling

May 5, 2025 · Background Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when

Liquid Cooling Battery Cabinet: Efficient Solution

To ensure reliability and maximize performance, these systems must operate under optimal conditions, with thermal management being a key factor. A pivotal innovation addressing this

Liquid Cooling Battery Cabinet: Innovation in Energy Systems

In the rapidly evolving landscape of energy storage, the efficiency and longevity of battery systems are paramount. A critical component ensuring optimal performance, especially in high

PCS-8812PB Liquid cooled energy storage cabinet

NR Electric Co. LtdPCS-8812 liquid cooled energy storage cabinet adopts liquid cooling technology with high system protection level to conduct fine temperature control for outdoor

Bullcube Outdoor Liquid Cooling Energy Storage

Nov 29, 2024 · 15 years life, 8,000 cycles. High effciency full liquid cooling heat dissipation, system cycle efficiency exceeds 88% Easy to Install Integrated

Introduction to Industrial and Commercial Liquid-Cooled

May 29, 2025 · This liquid cooling energy storage system provides ideal battery energy storage solutions for commercial and industrial applications. With four configuration options

6 FAQs about [Yemen Liquid Cooling Energy Storage Battery Cabinet Integration System]

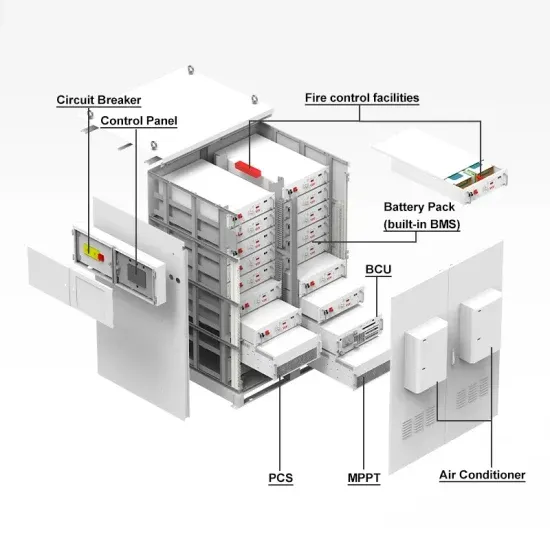

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

How long is a 5MWh liquid-cooling energy storage cabin?

The layout project for the 5MWh liquid-cooling energy storage cabin is shown in Figure 1. The cabin length follows a non-standard 20’GP design (6684mm length × 2634mm width × 3008mm height). Inside, there are 12 battery clusters arranged back-to-back, each with an access door for equipment entry, installation, debugging, and maintenance.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

Learn More

- How to charge the battery cabinet liquid cooling energy storage solar panels

- Energy storage liquid cooling battery cabinet design

- Energy storage liquid cooling battery cabinet manufacturing

- Huawei Paris Liquid Cooling Energy Storage Cabinet

- Democratic Republic of Congo liquid cooling energy storage cabinet site requirements

- Cuba Liquid Cooled Energy Storage Battery Cabinet Integrated System

- Energy storage cabinet liquid cooling production line

- Guinea-Bissau Liquid Cooling Energy Storage Cabinet Production

- Bridgetown Liquid Cooled Energy Storage Battery Cabinet Manufacturer Ranking

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.