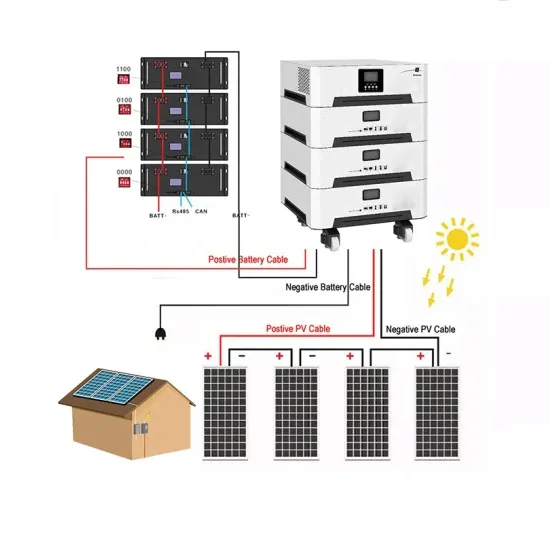

Energy storage cabinet energy storage battery production line

Safe Storage of Lithium-Ion Battery: Energy Storage Cabinet Environmental Protection: Energy storage cabinets protect the batteries and associated equipment from environmental elements

PCS-8812PB Liquid cooled energy storage cabinet

NR Electric Co. LtdPCS-8812 liquid cooled energy storage cabinet adopts liquid cooling technology with high system protection level to conduct fine temperature control for outdoor

Liquid cooling energy storage for production batteries

The cooling liquid absorbs heat from the battery module, then passes through a condenser for cooling before returning to the liquid tank. J. Energy Storage, 64 (2023), Article 107167.

Liquid Cooling Energy Storage Cabinet Production Process

To develop a liquid cooling system for energy storage, you need to follow a comprehensive process that includes requirement analysis, design and simulation, material selection,

energy storage container battery cabinet production process

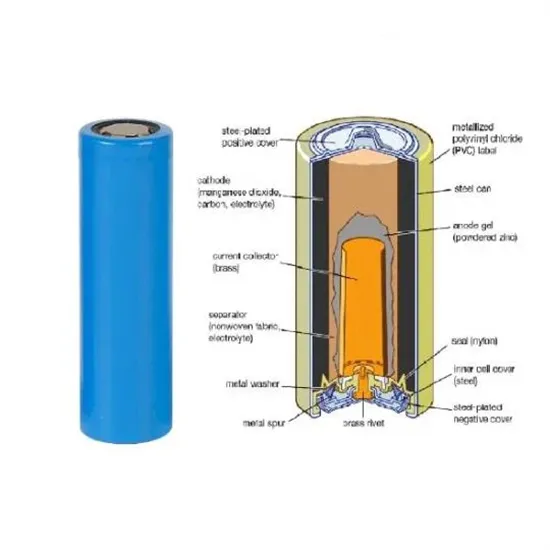

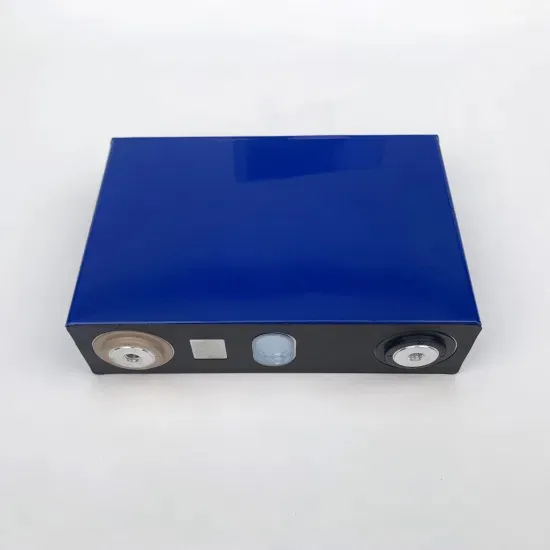

Production Line Guide | CHISAGE Battery Pack Process Flow The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code

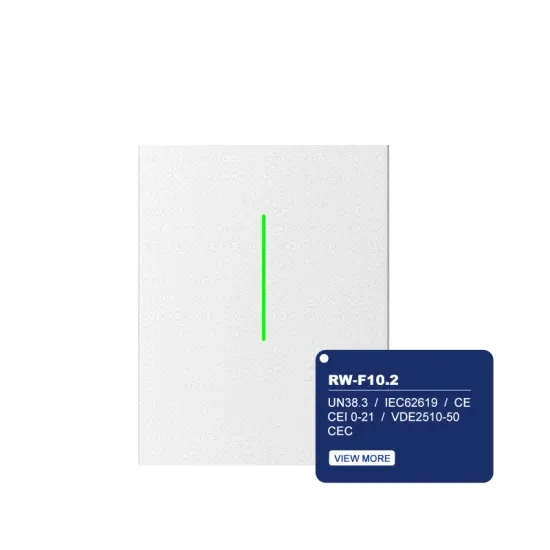

Linyang Power Key® Smart Liquid Cooling Integrated Cabinet

5 days ago · Energy StorageLinyang Power Key® Smart Liquid Cooling Integrated Cabinet PK-254 Power Key Smart Liquid Cooling Integrated Cabinet designed with highly integrated

Introduction to Industrial and Commercial Liquid-Cooled

May 29, 2025 · This liquid cooling energy storage system provides ideal battery energy storage solutions for commercial and industrial applications. With four configuration options

A review on the liquid cooling thermal management system

Dec 1, 2024 · In the above literature review, most of the studies utilize the battery module temperature, single cell surface temperature, Tmax-v between the batteries and between the

Energy storage liquid cooling cabinet manufacturing

While liquid cooling systems for energy storage equipment, especially lithium batteries, are relatively more complex compared to air cooling systems and require additional components

Power Solutions for Business: Efficient liquid cooling cabinet battery

Discover cutting-edge solutions for efficient energy management with our industrial and commercial systems. Maximize savings and sustainability with advanced liquid cooling cabinet

Liquid Cooling Battery Cabinet Production Line

Liquid-cooled Energy Storage Cabinet. o Lifespan of over 5 years; payback within 3 years. o Intelligent Liquid Cooling, maintaining a temperature difference of less than 2? within

Energy Storage Cabinet Production Line Manufacturers: Your

Why Does the Choice of Production Line Manufacturer Make or Break Your Energy Storage Business? As global renewable energy capacity surges by 18% year-over-year (2023 Gartner

Engineering Design of Liquid Cooling Systems in

Jul 3, 2025 · A well-designed liquid cooling system starts with a closed-loop architecture where coolant flows through channels embedded in or adjacent to

What is liquid-cooled battery cooling? – TYCORUN

Apr 1, 2022 · The principle of liquid-cooled battery heat dissipation is shown in Figure 1. In a passive liquid cooling system, the liquid medium flows through

Introduction to Industrial and Commercial Liquid-Cooled

May 29, 2025 · As an industry-leading BESS manufacturer with ISO 9001-certified production facilities, GSL Energy delivers premium battery energy storage solutions for demanding

Liquid Cooled Battery Energy Storage Systems

Jan 28, 2024 · Scalability and Modular Design Liquid cooling facilitates a more scalable and modular design for energy storage systems. The ability to efficiently cool individual battery

Design of cubic battery cabinet production line

The pack line process consists of three main phases: production, assembly, and packaging. The pack is a complex system comprising battery packs, shunts, soft connections, protective

Containerized Liquid Cooling ESS VE-1376L

Sep 8, 2023 · Vericom energy storage cabinet adopts All-in-one design, integrated container, refrigeration system, battery module, PCS, fire protection, environmental monitoring

Liquid-cooled energy storage battery production line

Introduction of Automatic Lithium Battery Pack Production Line. An automatic lithium battery pack production line is a facility equipped with specialized machinery and automated processes

Liquid Cooling Battery Cabinet: Efficient Solution

Innovations in Battery Cabinet Cooling Technology The sophistication of modern Battery Cabinet Cooling Technology is a testament to precision engineering. These are not simply add-on

DC Liquid Cooling Cabinet-Commercial & Industrial ESS -CHAM Battery

• Bidirectional shut-off Liquid Cooling pipes, eliminating the need for fluid drainage during installation and removal • Intelligent monitoring to reduce the frequency of manual inspections

Liquid-cooled Battery Cabinet | SHANGHAI ELECNOVA

The liquid-cooled battery cabinet adopts advanced cabinet-level liquid cooling and temperature balancing strategy. The cell temperature difference is less than 3°C, which further improves

Industrial and Commercial Liquid Cooled Energy Storage Cabinet

May 14, 2025 · Liquid cooling''s superior heat dissipation allows higher energy density (up to 280Wh/L) compared to air-cooled alternatives, making it ideal for space-constrained sites. A

100kW 232kWh C&I Liquid Cooling Cabinet Energy Storage

The GSL-CESS-100K232 Liquid Cooling ESS Cabinet is a high-performance energy storage system designed for industrial and commercial use. Equipped with integrated EMS for smart

Liquid Cooling Battery Cabinet: Efficient Solution

As companies like Hicorenergy continue to innovate with integrated and scalable solutions, the Liquid Cooling Battery Cabinet stands out as a cornerstone technology, empowering a more

Liquid Cooling Ess Cabinet

Jul 13, 2025 · Liquid Cooling Ess Cabinet, Find Details and Price about Energy Storage System LiFePO4 Battery for Bess Ess from Liquid Cooling Ess Cabinet - Shandong Huiyao Laser

Energy Storage Air Cooling Liquid Cooling

Jul 17, 2024 · energy storage, air cooling, liquid cooling, commercial & inductrial energy storage, liquid cooling battery module pack production line assembly

Learn More

- Energy storage cabinet liquid cooling production line

- Battery cabinet automated production line

- Energy storage liquid cooling battery cabinet manufacturing

- Battery cabinet production line manufacturers

- Yemen Liquid Cooling Energy Storage Battery Cabinet Integration System

- Ouagadougou domestic liquid cooling battery cabinet top ten brands

- Energy storage liquid cooling battery cabinet design

- Battery cabinet outdoor site production and processing

- Battery cabinet test system production plant

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.