Automate battery production with robotics and proven

Automation in battery production From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery

Battery cabinet production design drawings

Unified Power offers a complete line of battery cabinets for both UPS and Telecom Applications. These cabinets can be configured to match OEM cabinets and offer a competitive option for

Lithium Metal Solid Battery Production Line from China manufacturer

Mikrouna''s lithium metal solid-state battery production line is a leading product in the lithium battery industry. Integrating advanced production equipment and technology: can achieve high

Energy Storage Cabinet Production Line Manufacturers: Your

Why Does the Choice of Production Line Manufacturer Make or Break Your Energy Storage Business? As global renewable energy capacity surges by 18% year-over-year (2023 Gartner

Electrolyte Diffusion Standing Cabinet for Lithium Pouch Cell

Aug 19, 2025 · Electrolyte Diffusion Standing Cabinet for Lithium Pouch Cell Production Line, Find Details and Price about Vacuum Standing Box Lithium Battery from Electrolyte Diffusion

Battery production equipment and services

Jun 14, 2024 · BATTERY PACK ASSEMBLY and fitting of entire battery factories. Our aim is to offer the manufacturers of lithium-ion batteries a single source of supply for fitting their acilities

From Raw Materials to Power Giants: Inside the Large Energy

From Raw Materials to Power Giants: Inside the Large Energy Storage Cabinet Production Line You know what''s hotter than a Tesla battery pack in July? The race to build efficient large

Battery Production Line Manufacturers & Suppliers

Coating Machine manufacturer / supplier in China, offering Lithium Battery Production Line Solution Automation Production Equipment Packline, Industrial Battery Production Equipment

energy storage container battery cabinet production process

ABB containerized energy storage offers plug-in battery power ABB has responded to rapidly rising demand for low and zero emissions from ships by developing Containerized ESS – a

Lithium Battery Formation and Capacity Grading Cabinet

Oct 9, 2024 · China''s battery production capacity grew 56% year-over-year in 2023, reaching 1,200 GWh, with Tier 2 battery manufacturers accelerating automated formation line

Li-Ion battery assembly lines for energy storage systems

Aug 18, 2025 · BM-Rosendahl is a global leader in providing advanced manufacturing solutions for the battery industry, specializing in lithium-ion battery production lines tailored for energy

China Battery Formation Cabinet Manufacturers, Supplier

May 22, 2025 · The Battery Formation Cabinet from Dongguan Wangsheng Automation Equipment Co., Ltd. is engineered to address the demands of battery manufacturers seeking

6 FAQs about [Battery cabinet production line manufacturers]

What are the different types of battery production lines?

At present, the group has a variety of battery production lines such as lithium iron phosphate, ternary, nickel metal hydride, and now focuses on the field of energy storage, becoming a world-class professional manufacturer of new energy batteries.

Who are the top 10 battery energy storage manufacturers in China?

This article will focus on top 10 battery energy storage manufacturers in China including SUNWODA, CATL, GOTION HIGH TECH, EVE, Svolt, FEB, Long T Tech, DYNAVOLT, Guo Chuang, CORNEX, explore how they stand out in the fierce market competition and lead the industry forward. SUNWODA, founded in 1997, is a global leader in lithium-ion batteries.

Is China a leader in lithium-ion battery energy storage?

China, as one of the leaders in the world’s new energy industry, has gathered many companies that are deeply engaged in the field of lithium-ion battery energy storage and have advanced technology.

What is a CATL battery system?

In the field of battery energy storage, CATL battery systems cover ternary lithium-ion batteries and lithium iron phosphate batteries, which are widely used in new energy vehicles, electric mobility vehicles and energy storage systems, showing strong market adaptability and technical strength.

How has the battery industry changed in 2022?

From 162.30GWh in 2021 to 325GWh in 2022, the battery system production has increased significantly, highlighting the rapid expansion of the enterprise scale and the strong demand of the market.

Who is Dynavolt Battery Company?

DYNAVOLT is a joint-stock company founded by Shantou Humei Battery Co., Ltd. in 2001, with more than 30 years of battery manufacturing experience, and listed on the Shenzhen Stock Exchange in 2012.

Learn More

- Liquid Cooling Battery Cabinet Production Line

- Battery cabinet automated production line

- Battery cabinet production module site power supply

- Battery cabinet with built-in line base station

- Israel UPS battery cabinet full set production direct sales

- Ranking of battery cabinet manufacturers in Dublin

- Battery cabinet outdoor site production and processing

- Energy storage cabinet battery production and assembly equipment

- Battery cabinet rack production integrated system

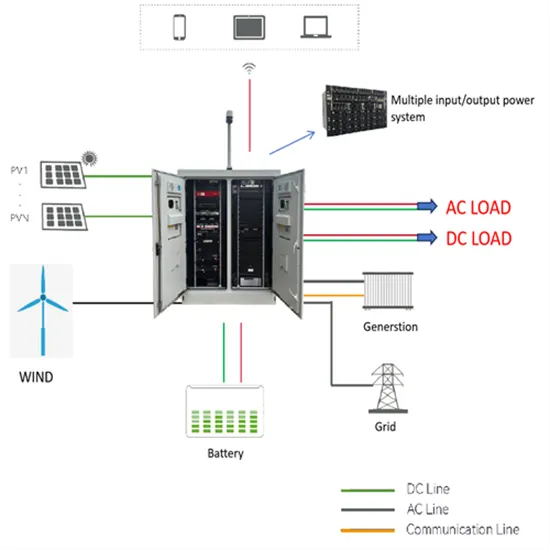

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.