Battery cabinet shell production line

Prismatic Aluminum Shell Battery Automated Production Line: This production line is suitable for over 90% of cylindrical products in the market, with a high degree of standardization. Main

Automated production line Manufacturers

Jul 1, 2025 · Small cylindrical lithium pack automated assembly line(BCYA-L05GE) Cylinder assembly line includes: manual loading, sort-ing machine, secondary code scanning,

Prismatic Battery Pack Production Line: Automated Solutions

Jun 7, 2025 · Guangdong Songke''s prismatic battery pack production line is. engineered for high-efficiency assembly of large-format batteries (280Ah+) used in stationary storage, solar farms,

Industrial & Commercial Energy Storage Module Production: Automated

Discover our state-of-the-art automated assembly line tailored for industrial and commercial energy storage module production. Featuring processes like laser welding, OCV testing, laser

Prismatic Battery Pack Assembly Line

Huiyao Laser''s automated production line is designed to achieve ideal efficiency, reduce cycle time and increase output. Automated processes, seamless workflow integration and real-time

Semi-Automatic Production Line for Battery Module Energy

Apr 2, 2025 · Semi-Automatic Production Line for Battery Module Energy Storage Cabinets for New Energy Vehicles, Find Details and Price about Prismatic Battery Pack Assembly Line

Automated energy storage battery cabinet production

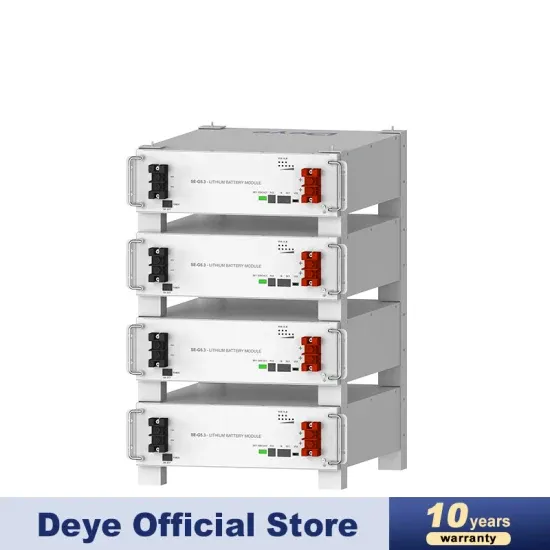

The SBS- Rack/Cabinet mounted lithium energy storage battery, uses high cycle lithium iron phosphate cells, high-performance BMS protection and management battery system, and can

Lithium Battery Module Pack Assembly Line

This advanced production line integrates a series of automated processes, including cell sorting, laser welding, module stacking, BMS installation, testing, and final pack assembly, tailored to

Automate battery production with robotics and proven

From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery production systems and supplies

Automated production of battery cabinets

Battery Cell Formation Turnkey Solution It is a real-time, fast and accurate in line modern production management system with immediate production control, status return, and report

4 FAQs about [Battery cabinet automated production line]

Why is battery assembly important?

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production.

What is a battery assembly solution?

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

What is the Jot battery assembly solution?

Watch the JOT Battery Assembly Solution in action. JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing.

What are the technical parameters of intelligent battery pack?

Intelligent battery pack finished product handling and packaging system. 3: Technical Parameters: Total production line length: 16 meters. Production capacity: Up to X battery packs per hour (customizable). Precision level: ±0.1mm positioning accuracy. Processing efficiency: 99.5% uptime.

Learn More

- Liquid Cooling Battery Cabinet Production Line

- Battery cabinet production line manufacturers

- Energy storage battery cabinet production line

- Energy storage cabinet liquid cooling production line

- Battery cabinet production site power supply

- EU Moisture-proof Battery Cabinet Production

- Battery Cabinet Production Cost Analysis

- How to calculate the production cost of battery cabinet

- Israel UPS battery cabinet full set production direct sales

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.