Container energy storage cabinet production line

Aug 6, 2021 · ABB''s containerized energy storage solution is a complete,self-contained battery solution for a large-scale marine energy storage. The batteries and all control,interface,and

Energy Storage Assembly Line: The Backbone of Modern

Jun 18, 2020 · a factory humming with robotic arms, conveyor belts stacked with lithium-ion cells, and engineers fine-tuning battery packs faster than you can say "renewable energy." Welcome

Energy storage outdoor cabinet production line

Our Battery Energy Storage Systems are designed for both outdoor and indoor locations, tailored to meet the needs of small and medium enterprises or industrial sites. We offer a versatile

picture of intelligent energy storage cabinet production line

Key technologies for smart energy systems: Recent developments, challenges, and research opportunities In 2019, global low-carbon energy production totaled 25,428 TWh, or 15.7

Energy storage cabinet assembly production line process

Energy storage cabinet assembly production line process What is the production process for chisage ESS battery packs? The production process for Chisage ESS Battery Packs consists

Energy Storage Cabinet Production Line

6 days ago · This production line is used for automatic assembly of energy storage cabinets. All single machine equipment and distributed systems interact with MES through a scheduling

Cube battery cabinet assembly production line

Automated Assembly Line for Large and Small Cylindrical Battery Automated assembly line, cylindrical battery production, laser welding, energy storage. 2:Introduction: This production

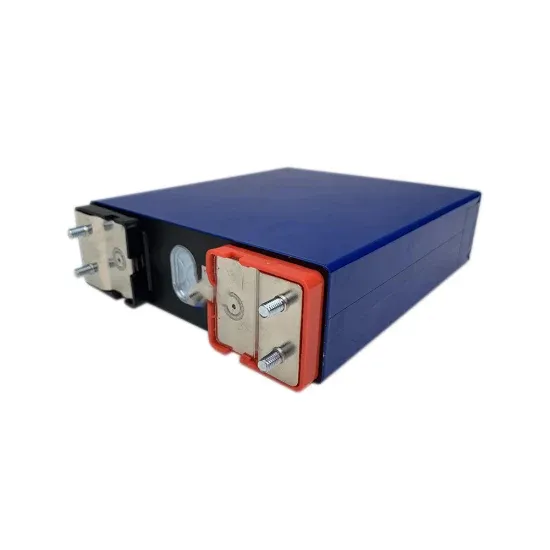

Exploring the World of Cabinet Type Energy Storage Battery

Jun 15, 2024 · In the realm of modern energy solutions, cabinet type energy storage battery factories play a crucial role in meeting the growing demands for sustainable power sources.

Energy storage cabinet production line capacity

Energy storage cabinet production line capacity What happened to energy storage systems? Industry attention was also devoted to the effectiveness of applications and the safety of

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Smart Energy Storage Cabinet Assembly Line-Battery PACK Production Line

A scientific and technological enterprise specializing in the research and development, production and sales of industrial laser processing equipment, has been deeply engaged in the new

Energy storage cabinet assembly production line process

The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning, laser cleaning, laser welding, pack assembly,

New energy battery cabinet production line

This production line is used for automatic assembly of energy storage cabinets. All single machine equipment and distributed systems interact with MES through a scheduling system, achieving

New energy storage cabinet production

The production line categories are complete, and there are delivery cases for household storage, commercial storage, energy storage battery packs, cabinet energy storage, and box energy

From Raw Materials to Power Giants: Inside the Large Energy Storage

You know what''s hotter than a Tesla battery pack in July? The race to build efficient large energy storage cabinet production lines as renewable energy goes mainstream. Let''s roll up our

Energy storage cabinet production and processing

Nov 30, 2022 · Shanghai ZOE Energy Storage Technology Co., Ltd., established in 2022, is dedicated to providing global users with safe, efficient, and intelligent energy storage product

ENERGY STORAGE CABINET PRODUCTION LINE

Battery production for energy storage power stations A battery energy storage system (BESS), battery storage power station, battery energy grid storage (BEGS) or battery grid storage is a

4 FAQs about [Energy storage battery cabinet production line]

How does the electric cabinet on the production line improve production efficiency?

The electric cabinet on the production line uses an AGV flexible design for transportation, which enhances production efficiency.

What is the production process for chisage ESS battery packs?

The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning, laser cleaning, laser welding, pack assembly, pack testing, and packaging for storage. Now, following in the footsteps of Chisage ESS, our sales engineers are ready to take you on a virtual tour!

What are battery cells made of?

Our battery cells are all made of new A-grade cells, with a single cell voltage of 3.2V, and the current production of battery Pack capacity is mainly 100Ah, 200Ah, and 280Ah. Use steel belts for pressing and packing, form 8 cells into 1 Module module, 2 Module modules into 1 Box Pack, and dissipate heat through ducts and fans.

What type of battery is used in a house?

Household batteries are mainly low-voltage 100Ah, 200Ah, and 300Ah batteries, including 5kWh rack-mounted battery packs, 5-10kWh wall-mounted battery packs, 5-20kWh stacked battery packs, and 15kWh floor-mounted battery packs.

Learn More

- Energy storage cabinet liquid cooling production line

- Energy storage battery cabinet photovoltaic production enterprise

- Fixed energy storage battery cabinet photovoltaic production

- Where to throw the energy storage cabinet battery for safe production

- Lithium battery energy storage cabinet production

- Morocco Casablanca Energy Storage Cabinet Battery Factory

- Battery exchange cabinet transformed into energy storage cabinet

- Energy storage battery cabinet operation steps

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.