Comprehensive review of energy storage systems

Jul 1, 2024 · Battery, flywheel energy storage, super capacitor, and superconducting magnetic energy storage are technically feasible for use in distribution networks. With an energy density

World''s Largest Single-unit Magnetic Levitation Flywheel

Nov 5, 2024 · On October 31, China''s first independently developed and patented magnetic levitation flywheel energy storage system—the largest of its kind globally—was successfully

Flywheel energy storage for Increased Grid Stability

Aug 9, 2022 · The flywheel is modular and offers unparalleled configurability in terms of power to energy ratio, which makes it the first dynamic energy storage system whose discharge

Grid-Scale Flywheel Energy Storage Plant

Dec 7, 2012 · Demonstrating frequency regulation using flywheels to improve grid performance Beacon Power will design, build, and operate a utility-scale 20 MW flywheel energy storage

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · The US Marine Corps are researching the integration of flywheel energy storage systems to supply power to their base stations through renewable energy sources. This will

A REVOLUTION IN ENERGY STORAGE

Jul 7, 2023 · Flywheel Energy Storage Systems in a Lithium-Ion-Centric Market Lithium-Ion represents 98%1 of the ESS market, but customers are looking for alternative ESS solutions

Flywheel technology generates energy efficiencies for metros

May 14, 2025 · With recent advances in energy storage technology, urban rail operators are harnessing the ability to reduce traction power consumption. Venky Krishnan director of

INSTALL THE TESLA REMOTE ENERGY METER AND CTS

This paper proposes an analysis method for energy storage dispatchable power that considers power supply reliability, and establishes a dispatching model for 5G base station energy

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Flywheel energy storage systems and their application with

Nov 18, 2021 · The rising demand for continuous and clean electricity supply using renewable energy sources, uninterrupted power supply to responsible consumers and an increas

What are the flywheel energy storage projects?

Mar 18, 2024 · Flywheel energy storage projects harness kinetic energy to store and release power efficiently, 2. They utilize rotating disks to maintain energy

China connects world''s biggest flywheel energy

Sep 16, 2024 · China has connected the world''s biggest flywheel system to its national grid. Built in the city of Changzhi, Shanxi Province, the $48m Dinglun

Flywheel Energy Storage in China: Current Trends and Future

Mar 6, 2025 · If you''re curious about cutting-edge energy storage solutions in China, you''ve probably heard whispers about flywheel energy storage. This article is for engineers, investors,

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Augmenting electric vehicle fast charging stations with

Sep 10, 2024 · This work investigates the economic efficiency of electric vehicle fast charging stations that are augmented by battery-flywheel energy storage. Energ

China Connects 1st Large-scale Flywheel Storage to Grid:

Sep 14, 2024 · China has successfully connected its 1st large-scale standalone flywheel energy storage project to the grid. The project is located in the city of Changzhi in Shanxi Province.

Construction Begins on China''s First Grid-Level

Jul 2, 2023 · The station consists of 12 flywheel energy storage arrays composed of 120 flywheel energy storage units, which will be connected to the Shanxi

Flywheel Energy Storage Costs Decoded: A 2024 Price

Feb 1, 2022 · Let''s cut through the techno-babble. Unlike battery systems that need coffee breaks (read: frequent maintenance), flywheels are the marathon runners of energy storage - but even

China Connects Its First Large-Scale Flywheel Storage Project

Sep 14, 2024 · China has connected to the grid its first large-scale standalone flywheel energy storage project in Shanxi Province''s city of Changzhi.The Dinglun Flywheel Energy Storage

6 FAQs about [What are the flywheel energy storage installation projects for communication base stations ]

What is the largest flywheel energy storage system in the world?

Image: Shenzen Energy Group. A project in China, claimed as the largest flywheel energy storage system in the world, has been connected to the grid. The first flywheel unit of the Dinglun Flywheel Energy Storage Power Station in Changzhi City, Shanxi Province, was connected by project owner Shenzen Energy Group recently.

How does a flywheel energy storage system work?

Flywheel energy storage technology works with a large, vacuum structure-encased spinning cylinder. To charge, electricity is used to drive a motor to spin the flywheel, and to discharge the motor acts as a generator to convert the spinning motion’s energy back into electricity.

Where is China's first large-scale flywheel energy storage project?

From ESS News China has connected to the grid its first large-scale standalone flywheel energy storage project in Shanxi Province’s city of Changzhi. The Dinglun Flywheel Energy Storage Power Station broke ground in July last year.

How many flywheel energy storage units are there in Shanxi?

The station consists of 12 flywheel energy storage arrays composed of 120 flywheel energy storage units, which will be connected to the Shanxi power grid. The project will receive dispatch instructions from the grid and perform high-frequency charge and discharge operations, providing power ancillary services such as grid active power balance.

What is the Dinglun flywheel energy storage power station?

The Dinglun Flywheel Energy Storage Power Station, the World’s Largest Flywheel Energy Storage Project, represents a significant step forward in sustainable energy. Its role in grid frequency regulation and support for renewable energy will help stabilize power systems as China continues to increase its reliance on wind and solar energy.

What is China's first grid-connected flywheel energy storage project?

The 30 MW plant is the first utility-scale, grid-connected flywheel energy storage project in China and the largest one in the world. From ESS News China has connected to the grid its first large-scale standalone flywheel energy storage project in Shanxi Province’s city of Changzhi.

Learn More

- What are the flywheel energy storages for Liberia s optical fiber communication base stations

- Regulations on the entry of flywheel energy storage into communication base stations

- How much flywheel energy storage is there in Cameroon communication base stations

- Understanding of flywheel energy storage equipment and functions of communication base stations

- What are the battery energy storage systems for communication base stations

- Quality of flywheel energy storage cabinets for communication base stations in Africa

- Does Kyrgyzstan have flywheel energy storage for communication base stations

- What are the manufacturers of battery energy storage systems for Manila communication base stations

- Construction skills of flywheel energy storage for communication base stations

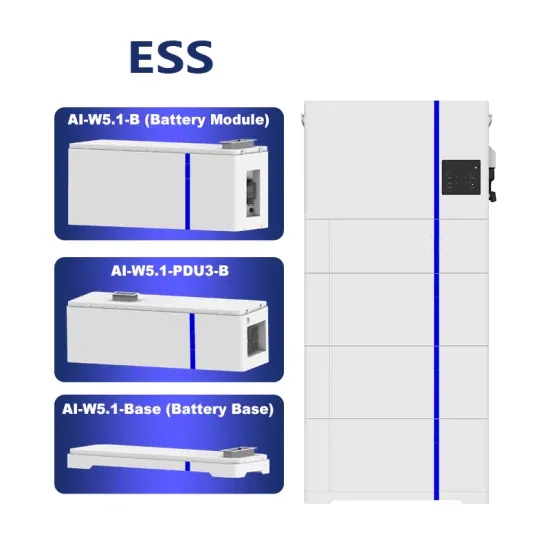

Industrial & Commercial Energy Storage Market Growth

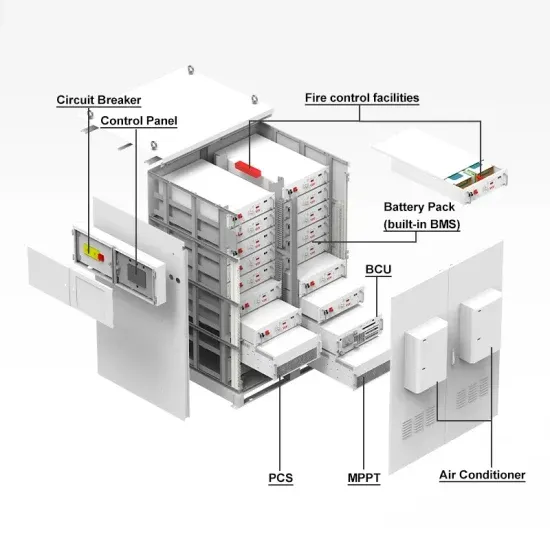

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.