Development of a High Specific Energy Flywheel Module,

Aug 6, 2020 · a rapidly spinning wheel - with 50 times the Storage capacity of a lead-acid battery As the flywheel is discharged and spun down, the stored rotational energy is transferred back

Ningxia Power''s Magnetic Suspension Flywheel Energy Storage

Apr 6, 2022 · The two standards clarify the composition of magnetic suspension flywheel energy storage systems, technical specifications and testing requirements for energy storage systems

Legal Issues on the Construction of Energy Storage Projects

As of July 2022, the effective laws, regulations and policies for the pumped-storage industry mainly include: "Pumped Storage Medium and Long-term Development Plan (2021–2035),"

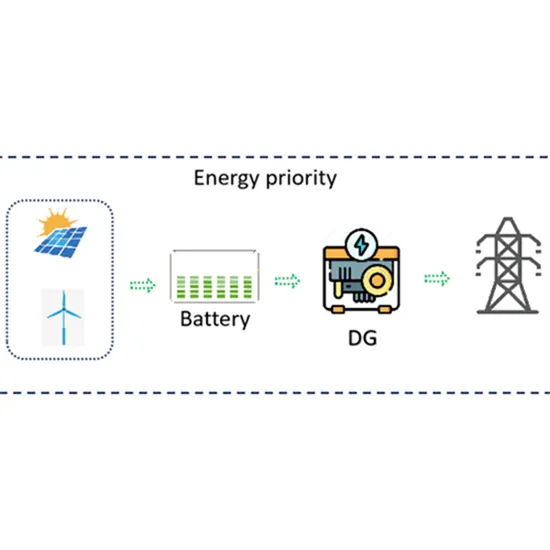

Coordinated Control of Flywheel and Battery Energy Storage

Apr 10, 2025 · Due to the inherent slow response time of diesel generators within an islanded microgrid (MG), their frequency and voltage control systems often struggle to effectively

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · The US Marine Corps are researching the integration of flywheel energy storage systems to supply power to their base stations through renewable energy sources. This will

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

IEEE TRANSACTIONS ON POWER SYSTEMS, SUBMITTED

Jan 23, 2023 · rage Systems (BESSs) and Flywheel Energy Storage Systems (FESSs), considering all relevant stages in the frequency control process. Communication delays are

A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

World''s Largest Single-unit Magnetic Levitation Flywheel

Nov 5, 2024 · On October 31, China''s first independently developed and patented magnetic levitation flywheel energy storage system—the largest of its kind globally—was successfully

Research on the application of flywheel energy storage

The application case of the flywheel energy storage device in engineering has verified that the flywheel energy storage device has a good voltage stabilization effect, with an average energy

Flywheel Energy Storage: Alternative to Battery

Oct 5, 2024 · As the energy grid evolves, storage solutions that can efficiently balance the generation and demand of renewable energy sources are critical.

A review of flywheel energy storage rotor materials and

Oct 19, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Modeling and Control of Flywheel Energy Storage System

May 15, 2023 · Flywheel energy storage has the advantages of fast response speed and high energy storage density, and long service life, etc, therefore it has broad application prospects

WhitePaper-Safety of Flywheel Storages Systems

Aug 8, 2025 · Flywheel technology is useful for many energy storage applications, such as, enhanced frequency regulation, voltage support, inertia provision or peak shaving. Superior to

Grid-Scale Flywheel Energy Storage Plant

Dec 7, 2012 · Demonstrating frequency regulation using flywheels to improve grid performance Beacon Power will design, build, and operate a utility-scale 20 MW flywheel energy storage

Optimised configuration of multi-energy systems

Dec 30, 2024 · Optimised configuration of multi-energy systems considering the adjusting capacity of communication base stations and risk of network congestion

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully

General technical requirements for flywheel energy storage

Apr 30, 2020 · This standard specifies the general requirements, performance requirements and test methods of flywheel energy storage systems (single machine). This standard is applicable

6 FAQs about [Regulations on the entry of flywheel energy storage into communication base stations]

Do flywheel energy storage systems provide fast and reliable frequency regulation services?

Throughout the process of reviewing the existing FESS applications and integration in the power system, the current research status shows that flywheel energy storage systems have the potential to provide fast and reliable frequency regulation services, which are crucial for maintaining grid stability and ensuring power quality.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

What is a flywheel energy storage system?

A typical flywheel energy storage system , which includes a flywheel/rotor, an electric machine, bearings, and power electronics. Fig. 3. The Beacon Power Flywheel , which includes a composite rotor and an electric machine, is designed for frequency regulation.

Can a flywheel energy storage system control frequency regulation after micro-grid islanding?

Arani et al. present the modeling and control of an induction machine-based flywheel energy storage system for frequency regulation after micro-grid islanding. Mir et al. present a nonlinear adaptive intelligent controller for a doubly-fed-induction machine-driven FESS.

What is China's first grid-level flywheel energy storage frequency regulation power station?

This project represents China's first grid-level flywheel energy storage frequency regulation power station and is a key project in Shanxi Province, serving as one of the initial pilot demonstration projects for "new energy + energy storage."

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Learn More

- Regulations on the establishment of flywheel energy storage in communication base stations

- Wholesale of flywheel energy storage equipment for communication base stations in Cote d Ivoire

- What are the flywheel energy storage installation projects for communication base stations

- Flywheel energy storage work for rural communication base stations

- Flywheel energy storage power equipment for communication base stations

- Which company is the best flywheel energy storage equipment for North African communication base stations

- Does Kyrgyzstan have flywheel energy storage for communication base stations

- Quality of flywheel energy storage cabinets for communication base stations in Africa

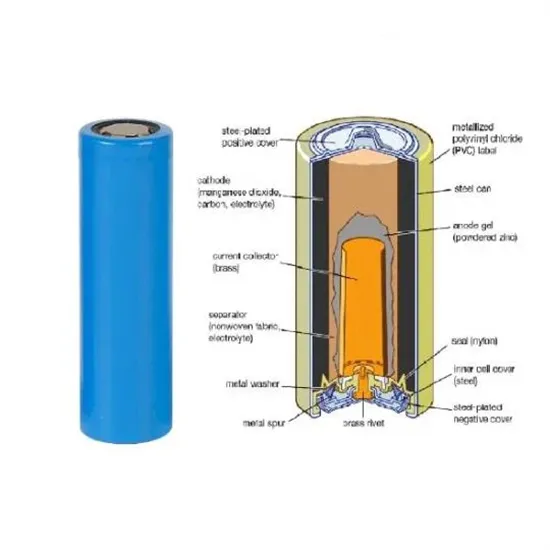

- Battery energy storage system indicators for communication base stations

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.