Energy Storage Regulation Strategy for 5G Base Stations

Dec 18, 2023 · The rapid development of 5G has greatly increased the total energy storage capacity of base stations. How to fully utilize the often dormant base station energy storage

State switch control of magnetically suspended flywheel energy storage

Jan 27, 2025 · The magnetically suspended flywheel energy storage system (MS-FESS) is an energy storage equipment that accomplishes the bidirectional transfer between electric energy

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · The US Marine Corps are researching the integration of flywheel energy storage systems to supply power to their base stations through renewable energy sources. This will

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and

Analysis of a flywheel energy storage system for light rail

Jul 15, 2016 · The introduction of flywheel energy storage systems in a light rail transit train is analyzed. Mathematical models of the train, driving cycle and fly

Flywheel energy storage systems and their application with

Nov 18, 2021 · The rising demand for continuous and clean electricity supply using renewable energy sources, uninterrupted power supply to responsible consumers and an increas

Flywheel Energy Storage for Telecom Applications

Flywheel energy storage is an efficient, environmentally friendly and sustainable solution to handle short power disturbances at base stations.This Master of Science thesis, in collaboration with

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss

Development of a High Specific Energy Flywheel Module,

Aug 6, 2020 · Flywheels can store energy kinetically in a high speed rotor and charge and discharge using an electrical motor/generator. Wheel speed is determined by simultaneously

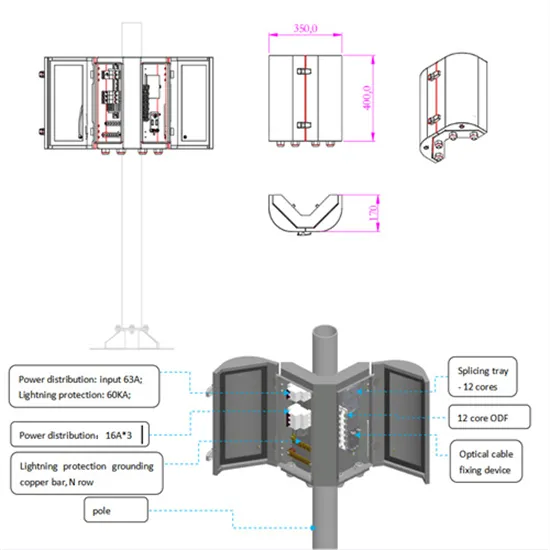

Revolutionising Connectivity with Reliable Base Station Energy Storage

Jun 12, 2025 · Base station energy storage refers to batteries and supporting hardware that power the BTS when grid power is unavailable or to smooth out intermittent renewable sources like

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy storage (FESS),

Mobile base stations will use flywheel energy storage

Can a high speed flywheel energy storage system help mobile applications? The need for low cost reliable energy storage for mobile applications is increasing. One type of battery that can

Flywheel Energy Storage for Electric Vehicle (EV)

Sep 23, 2024 · The operating principle of flywheel energy storage technology is based on the conversion of electrical energy to kinetic energy. Upon drawing

Distributed fixed-time cooperative control for flywheel energy storage

Apr 15, 2024 · The aim of the cooperative control is to achieve two objectives: the output power of the flywheel energy storage systems (FESSs) should meet the reference power requirement,

Augmenting electric vehicle fast charging stations with

Sep 10, 2024 · This work investigates the economic efficiency of electric vehicle fast charging stations that are augmented by battery-flywheel energy storage. Energ

A Control Algorithm for Electric Vehicle Fast Charging Stations

Nov 17, 2015 · A Flywheel Energy Storage System (FESS) is a mechanical energy storage system that stores energy through a high-speed rotational flywheel driven by an integrated

Energy and environmental footprints of flywheels for utility

Jan 1, 2021 · The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

6 FAQs about [Flywheel energy storage work for rural communication base stations]

What are flywheel energy storage systems?

Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint. Various techniques are being employed to improve the efficiency of the flywheel, including the use of composite materials.

Are flywheel batteries a good energy storage system?

Flywheel energy storage systems are suitable and economic al when frequent charge and discharge cycles are required. Fu rthermore, flywheel batteries have high power density and a low environmental footprint. Various techniques are being employed to improve the efficiency of the flywheel, including the us e of co mposite materials.

How will flywheel energy storage help the US Marines?

The US Marine Corps are researching the integration of flywheel energy storage systems to supply power to their base stations through renewable energy sources. This will reduce the dependence on chemical batteries and, ultimately cost of running . 7.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Can flywheel energy storage improve wind power quality?

FESS has been integrated with various renewable energy power generation designs. Gabriel Cimuca et al. proposed the use of flywheel energy storage systems to improve the power quality of wind power generation. The control effects of direct torque control (DTC) and flux-oriented control (FOC) were compared.

How do fly wheels store energy?

Fly wheels store energy in mechanical rotational energy to be then converted into the required power form when required. Energy storage is a vital component of any power system, as the stored energy can be used to offset inconsistencies in the power delivery system.

Learn More

- How much flywheel energy storage is there in Cameroon communication base stations

- Construction of battery energy storage system for rural communication base stations

- Regulations on the establishment of flywheel energy storage in communication base stations

- Flywheel energy storage for communication base stations on the roof of high-rise buildings

- Construction skills of flywheel energy storage for communication base stations

- Which company is the best flywheel energy storage equipment for North African communication base stations

- List of flywheel energy storage equipment for communication base stations

- One has several communication base stations with flywheel energy storage

- Whose company is the flywheel energy storage for communication base stations

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.