Energy‐Efficient Base Stations | part of Green Communications

Aug 29, 2022 · With the explosion of mobile Internet applications and the subsequent exponential increase of wireless data traffic, the energy consumption of cellular networks has rapidly

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

The key factors in the design and construction of advanced flywheel

Oct 10, 1996 · This paper develops a flywheel energy storage system from first principles and illustrates this with a design for Pirouette/sup TM/ by International Energy Syst

Modeling and Control of Flywheel Energy Storage System

May 15, 2023 · Flywheel energy storage has the advantages of fast response speed and high energy storage density, and long service life, etc, therefore it has broad application prospects

The key factors in the design and construction of advanced

The features of this technology that are beneficial to the operator are identified. The authors discuss flywheel shape, suspension system, power transfer, mechanical failure management,

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extens

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electrical power system into one that is fully sustainable yet low

Flywheel energy and power storage systems

Feb 1, 2007 · During that time several shapes and designs where implemented, but it took until the early 20th century before flywheel rotor shapes and rotational stress were thoroughly

Energy and environmental footprints of flywheels for utility

Jan 1, 2021 · The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

基于一致性算法的飞轮储能群组双层分布式协同控制

Nov 15, 2023 · This layer incorporates an average voltage observer and a state equation relying on flywheel energy indicators. It solely utilizes communication between adjacent energy

Design and Construction of 10 kWh Class Flywheel Energy Storage

Jan 4, 2025 · A superconductor flywheel energy storage system (SFES) is an electro-mechanical battery which transforms electrical energy into mechanical energy for storage, and vice versa.

Energy Storage Regulation Strategy for 5G Base Stations

Dec 18, 2023 · The rapid development of 5G has greatly increased the total energy storage capacity of base stations. How to fully utilize the often dormant base station energy storage

Flywheel Storage Systems | SpringerLink

Dec 17, 2019 · The components of a flywheel energy storage systems are shown schematically in Fig. 5.4. The main component is a rotating mass that is held via magnetic bearings and

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

6 FAQs about [Construction skills of flywheel energy storage for communication base stations]

What is a flywheel energy storage system?

Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies. A FESS consists of several key components: (1) A rotor/flywheel for storing the kinetic energy. (2) A bearing system to support the ro-tor/flywheel.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Why are high-strength steel flywheels a good choice?

High-strength steel flywheels have a high energy density (volume-based energy) due to their high mass density. Furthermore, they are superior to composite ones regarding thermal conductivity and design data availability, such as SN curves and fracture toughness.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Do flywheels provide bus regulation and attitude control capability?

Flywheels have been experimentally shown to provide bus regulation and attitude control capability in a laboratory. A sizing code based on the G3 flywheel technology level was used to evaluate flywheel technology for ISS energy storage, ISS reboost, and Lunar Energy Storage with favorable results.

Can flywheel energy storage improve wind power quality?

FESS has been integrated with various renewable energy power generation designs. Gabriel Cimuca et al. proposed the use of flywheel energy storage systems to improve the power quality of wind power generation. The control effects of direct torque control (DTC) and flux-oriented control (FOC) were compared.

Learn More

- What are the flywheel energy storage installation projects for communication base stations

- The construction unit of the battery energy storage system for Nordic communication base stations is

- Construction standards for battery energy storage systems at Vatican communication base stations

- List of flywheel energy storage equipment for communication base stations

- Regulations on the entry of flywheel energy storage into communication base stations

- Flywheel energy storage for communication base stations on the roof of high-rise buildings

- How much flywheel energy storage is there in Cameroon communication base stations

- 5g communication base station flywheel energy storage construction

- Does Kyrgyzstan have flywheel energy storage for communication base stations

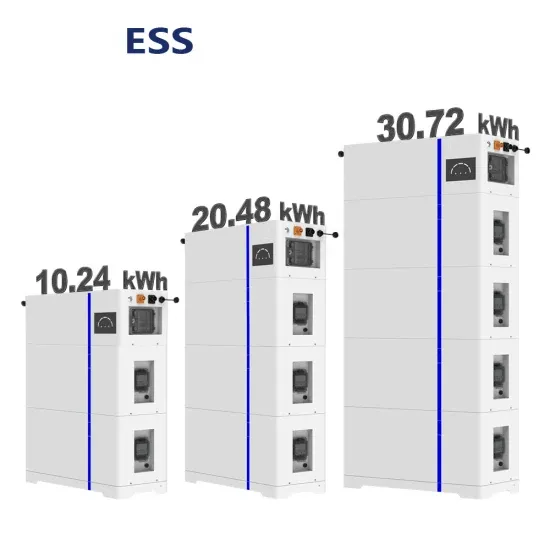

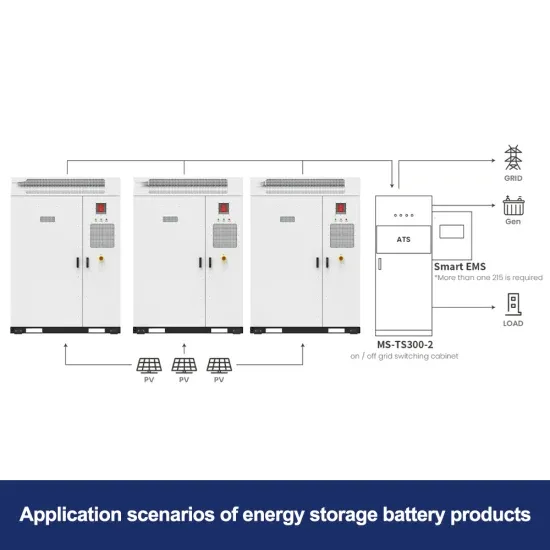

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.