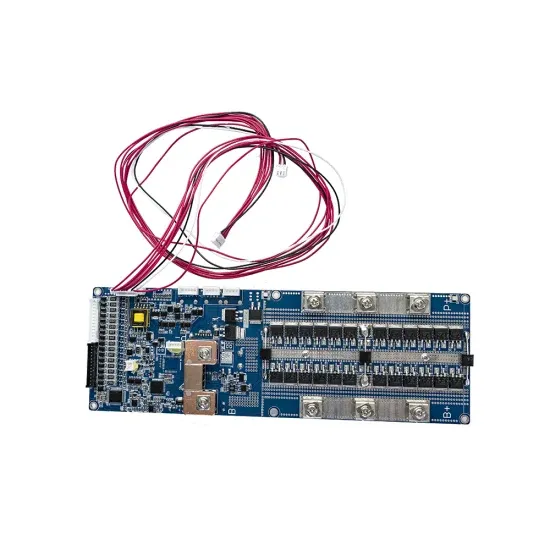

BMS JK SMART INVERTER line for home energy storage

Jun 16, 2025 · BMS JK SMART INVERTER line for home energy storage management. The JK BMS Inverter for managing energy storage systems is a solution that combines a SMART

High-voltage inverter | EV traction inverter | Eaton

Feb 1, 2024 · The high-voltage inverter converts direct current (DC) from the batteries or generator to alternating current (AC) to power the traction drive

Single Phase Low Voltage Hybrid Inverter Manufacturer,

As China Single Phase Low Voltage Hybrid Inverter manufacturer and suppliers, NingBo Deye Inverter Technology Co.,Ltd offer Single Phase Low Voltage Hybrid Inverter for sale

高压变频器-高压变频器厂家-深圳市英威腾电气股份有限公司

英威腾高压变频器采用了主流的功率单元串联技术,以DSP+ARM+FPGA三核处理器为控制核心,集成了当前先进的电机矢量控制算法,控制精度高,响应速度快,低频大转矩,十分适用于

SUN-5/6/8/10/12/15/20/25K-SG01HP3-EU-AM2 Inverter

Jun 8, 2010 · PV Input Voltage (V) NingBo Deye Inverter Technology Co.,Ltd is China SUN-5/6/8/10/12/15/20/25K-SG01HP3-EU-AM2 inverter company and supplier。

Components and Functions of Low-Voltage Inverters in

Aug 30, 2024 · Learn about the core components and key functions of low-voltage inverters and how to improve industrial automation efficiency through speed control, energy saving and

The 10 BEST Campervan Inverters – 2024 Power

May 7, 2024 · The Best Campervan Inverters It can be difficult to decide on which inverter is the best for your van, especially considering how many styles and

低压变频器-卧龙电气驱动集团股份有限公司

低压变频器产品及解决方案 作为全球知名的电机及驱动解决方案的制造商,卧龙集团股份有限公司创建于1984年,经过四十年的创新发展、已在中国、越南、

WD1000/WD3000系列低压变频器-低压变频器-卧

低压变频器工程型变频器是适用于全领域的新一代全能型交流传动设备,两象限,四象限可选,兼容性强和灵活性大。可以为满足各个行业的不同需求,可定

Battery Equalizer DC 12V 24V Batteries Voltage Inverter

Battery Equalizer DC 12V 24V Batteries Voltage Inverter Balancer Description Used for connecting two batteries in series, used in a 24V battery pack Led indicator Low loss and

High Voltage Inverters & Batteries | Solar Warehouse SA

What is a High Voltage Inverter? A high voltage inverter is a device that converts the direct current (DC) electricity from solar panels or batteries into high voltage alternating current (AC)

High-voltage VS Low-voltage Inverters: What''s the difference?

May 14, 2025 · Confused about high-voltage vs low-voltage inverters? This easy-to-read guide explains the differences, pros, cons, and real-world uses—perfect for anyone exploring solar

中压变频器-深圳市英威腾电气股份有限公司

英威腾中压变频器广泛应用于矿山行业采煤机、连采机、梭车、输送机、提升机、绞车、乳化液泵、潜油电泵、矿用风机、水泵等设备,具有驱动性能优异、多机功能平衡同步、低频大扭矩平

Vertiv MegaVert-G系列中压变频器

MegaVert中压变频器是维谛技术采用行业领先的电力电子技术自主研发生产的IGBT型中压变频器,采用SPWM (Sinusoidal PWM)控制技术,实现对中压电动机的变频调速控制。 通过提高设

Troubleshooting Inverter Problems: A Step-by-Step Guide

Nov 25, 2023 · Inverters play a crucial role in many modern systems, converting DC power from sources like batteries or solar panels into AC power that can be used by household

High-voltage inverter | EV traction inverter | Eaton

Feb 1, 2024 · Explore Eaton''s high-voltage inverter converts direct current (DC) from the batteries or generator to alternating current (AC) to power the traction

Infineon high voltage Inverter Application Presentation

May 25, 2025 · Infineon''s industry-leading discrete IGBTs are compatible with Empower''s latest generation inverter in terms of packaging. Together with the high current density, ultra-low

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · Description This reference design realizes a reinforced isolated three-phase inverter subsystem using isolated IGBT gate drivers and isolated current/voltage sensors. The

5 FAQs about [Voltage inverter b9zz560151]

What is a high voltage inverter?

The high voltage inverters used by ZF dispose of a nominal voltage of from 350 to 650 volts. They control the asynchronous motors of the ZF drives and are optimized on the electric drive system. Do you have any questions about our products, technical details or spare parts? Then get in touch with us using this contact form!

What can a ZF inverter provide?

What can Inverter provide? The high voltage inverters used by ZF dispose of a nominal voltage of from 350 to 650 volts. They control the asynchronous motors of the ZF drives and are optimized on the electric drive system.

Can SBH series high voltage inverters be used in coal transportation system?

This article presents the application of SBH series high voltage inverters in the coal transportation system 5×350MW power plant. The use of medium voltage inverters not only allows for smooth and continuous speed regulation of belt conveyors, but also enhances the economic efficiency of their operation.

Why should you use a medium voltage inverter in a belt conveyor?

The use of medium voltage inverters not only allows for smooth and continuous speed regulation of belt conveyors, but also enhances the economic efficiency of their operation. In long-distance and high-capacity belt conveyor projects, multiple drive units are often employed. The key lies in achieving torque balance between different drives.

What are ABB power converters & controllers?

ABB offers a comprehensive range of power converters and controllers for use in a wide range of applications across all industries. ABB power converters and controllers help customers to generate and use energy efficiently. They are designed for reliable operation even under the most demanding conditions, and for low life cycle costs.

Learn More

- Inverter output high voltage and low current

- 350w inverter voltage to 220v

- Can the DC 12V voltage be supplied to the inverter

- Argentina voltage stabilizer inverter manufacturer

- Inverter increases peak voltage

- The maximum grid voltage that the inverter can withstand

- 27V inverter input voltage

- The difference between high voltage and low voltage inverter

- Inverter acts as a voltage source

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

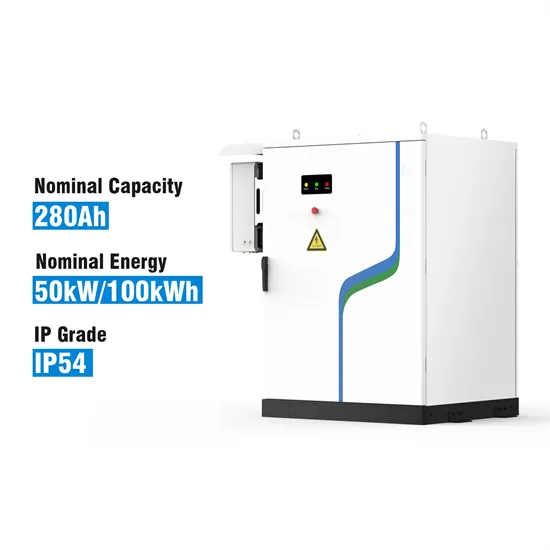

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.