A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Rotor Design for High-Speed Flywheel Energy Storage

Sep 25, 2018 · Contemporary flywheel energy storage systems, or FES systems, are frequently found in high-technology applications. Such systems rely on advanced high-strength materials

World''s Largest Single-unit Magnetic Levitation Flywheel

Nov 5, 2024 · On October 31, China''s first independently developed and patented magnetic levitation flywheel energy storage system—the largest of its kind globally—was successfully

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · This project has advanced the commercial readiness of flywheel technology by enhancing the product design, confirming performance and reliability, advancing

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy sto

Flywheel Energy Storage Costs Decoded: A 2024 Price

Feb 1, 2022 · Why Should You Care About Flywheel Project Economics? If you''re reading this, you''re probably wondering: "How much does a flywheel energy storage project ACTUALLY

Energy and environmental footprints of flywheels for utility

Jan 1, 2021 · The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

(PDF) Design and Analysis of Flywheel for

May 5, 2017 · The flywheel is the simplest device for mechanical battery that can charge/discharge electricity by converting it into the kinetic energy of a rotating

Top 10 flywheel energy storage manufacturers in

4 days ago · Flywheel energy storage is widely used in electric vehicle batteries, uninterruptible power supplies, uninterrupted power supply of wind power

China Connects 1st Large-scale Flywheel Storage to Grid:

Sep 14, 2024 · China has successfully connected its 1st large-scale standalone flywheel energy storage project to the grid. The project is located in the city of Changzhi in Shanxi Province.

Kinetix Provides Grid-scale flywheel energy storage

Aug 18, 2025 · We''re making clean energy affordable by reinventing flywheel storage that''s 10x more cost-effective than existing solutions. By dramatically

Metallic materials for energy storage flywheel rotors

This paper reviews the research and development of metallic materials for flywheel rotors and hubs, and processing and manufacturing technologies for rotors and hubs including casting,

CHN Energy Makes Major Breakthrough in Flywheel Energy Storage

Jan 9, 2025 · The project comprises three 4MW/1MWh flywheel units, for a total capacity of 12MW/3MWh. Integrated with two 330MW thermal power units at the Penglai facility, the

6 FAQs about [Flywheel energy storage manufacturing unit]

What is flywheel energy storage?

Flywheel energy storage is widely used in electric vehicle batteries, uninterruptible power supplies, uninterrupted power supply of wind power generation systems, high-power pulse discharge power supplies, etc. This article has compiled top 10 flywheel energy storage manufacturers in China for reference. Company profile:

What is the largest flywheel energy storage system in the world?

Image: Shenzen Energy Group. A project in China, claimed as the largest flywheel energy storage system in the world, has been connected to the grid. The first flywheel unit of the Dinglun Flywheel Energy Storage Power Station in Changzhi City, Shanxi Province, was connected by project owner Shenzen Energy Group recently.

Where is China's first large-scale flywheel energy storage project located?

China has successfully connected its 1st large-scale standalone flywheel energy storage project to the grid. The project is located in the city of Changzhi in Shanxi Province. The power output of the facility is 30 MW and it is equipped with 120 high-speed magnetic levitation flywheel units.

Where is Dinglun flywheel energy storage power station located?

The first flywheel unit of the Dinglun Flywheel Energy Storage Power Station in Changzhi City, Shanxi Province, was connected by project owner Shenzen Energy Group recently. Pictured above, it has a total installed capacity of 30MW with 120 high-speed magnetic levitation flywheel units.

Is flywheel energy storage technology underutilized?

Despite its benefits, flywheel energy storage technology remains underutilized. According to the China Energy Storage Alliance (CNESA), flywheel energy storage accounts only for 0.1% of the total capacity of 13.1 gigawatts provided by new energy storage systems in China.

What is flywheel technology?

Flywheel technology is a method of energy storage that uses the principles of rotational kinetic energy. A flywheel is a mechanical device that stores energy by spinning a rotor at very high speeds.

Learn More

- Huawei flywheel energy storage unit flexibility

- Supercapacitor flywheel energy storage

- How much does a flywheel energy storage room for a communication base station cost

- Flywheel energy storage transmission device

- Flywheel energy storage should be AC or DC

- Energy storage flywheel 2971186Z space

- How much flywheel energy storage is there in Cameroon communication base stations

- Flywheel energy storage power station configuration

- New Energy Power Station Energy Storage Flywheel

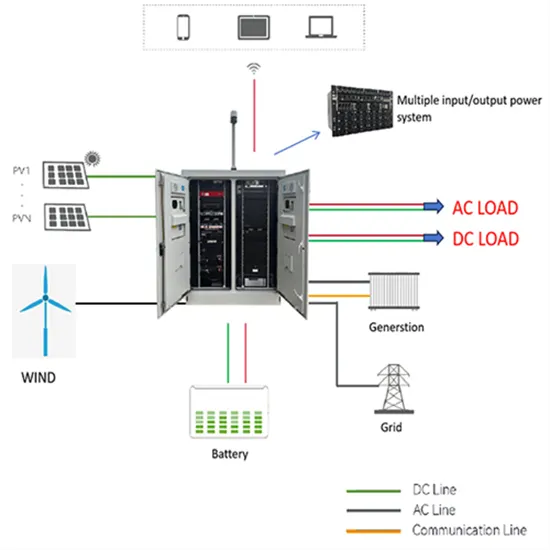

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.