What power supply should the flywheel energy storage

A typical flywheel energy storage system includes a flywheel/rotor,an electric machine,bearings,and power electronics. Fig. 3. The Beacon Power Flywheel,which includes a

Applications of flywheel energy storage system on load

Mar 1, 2024 · The power regulation topology based on flywheel array includes a bidirectional AC/DC rectifier inverter, LC filter, flywheel energy storage array, permanent magnet

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheel Energy Storage (FES) system is an electromechanical storage system in which energy is stored in the kinetic energy of a rotating mass. Flywheel systems are

Technology: Flywheel Energy Storage

Oct 30, 2024 · System Design Each FESS module has a power electronics module which allows its AC motor-generator to interface with a DC bus that is common to several FESS modules.

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy storage (FESS),

(PDF) Implementation and Control of an AC/DC/AC

May 22, 2012 · An all-electric driveline based on a double wound flywheel, connected in series between main energy storage and a wheel motor, is presented. The flywheel works as a

Simulation of Flywheel Energy Storage System Controls

Aug 6, 2020 · the flywheel energy storage model has been presented. This model incor-porates an electro-mechanical machine model, which is able to simulate energy transfer to and from

Flywheel Energy Storage System for Electric Start and an

Jan 23, 2024 · Flywheel technology overcomes some of the shortcomings of today''s energy storage systems by having an extremely high cyclic-life, limited temperature sensitivity, no

Mitigation effect of flywheel energy storage on the

Dec 1, 2023 · Shen et al. (2020) proposed a hybrid energy storage technology including flywheel energy storage and battery energy storage for the DC microgrid system of photovoltaic power

Flywheel energy storage principle video tutorial

This document describes a flywheel energy storage system. It includes an introduction, block diagram, theory of operation, design, components, circuit diagram, advantages and

Design and analysis of a flywheel energy storage system fed

Jan 1, 2022 · Abstract This paper presents design, optimization, and analysis of a flywheel energy storage system (FESS) used as a Dynamic Voltage Restorer (DVR). The first purpose of the

Flywheel energy and power storage systems

Feb 1, 2007 · Requirements for standardized electric power have made most flywheel system designers elect variable speed AC generators (to accommodate the gradual slowing of the

Flywheel Energy Storage

Jan 12, 2024 · DC flywheel energy storage maintenance requirements vary depending on the specific flywheel design features, but are generally less frequent and less expensive than for

The High-speed Flywheel Energy Storage System

Sep 25, 2018 · A flywheel energy storage system converts electrical energy supplied from DC or three-phase AC power source into kinetic energy of a spinning mass or converts kinetic

Assessment of photovoltaic powered flywheel energy storage

Nov 1, 2023 · Energy storage and power conditioning are the two major issues related to renewable energy-based power generation and utilisation. This work discusses

Technology: Flywheel Energy Storage

Oct 30, 2024 · Flywheel energy storages are commercially available (TRL 9) but have not yet experienced large-scale commercialisation due to their cost disadvantages in comparison with

A Novel Flywheel Array Energy Storage System with DC

Oct 21, 2020 · Flywheel Energy Storage System (FESS) becomes more attractive than other energy storage technologies due to its significant advantages. Single flywheel has limi

A comprehensive review of Flywheel Energy Storage System

Jan 1, 2017 · The idea of regenerating energy management for pulse load consisting of DC and AC loads, which need DC and AC power distribution systems, has been studied in [223], and it

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Flywheel Energy Storage System based on boost DC-AC

An additional DC-DC boost converter is used in conventional configuration of Flywheel Energy Storage System (FESS) to regulate the output voltage during flywheel low speeds. This paper

Artificial intelligence computational techniques of flywheel energy

Dec 1, 2024 · However, the intermittent nature of these RESs necessitates the use of energy storage devices (ESDs) as a backup for electricity generation such as batteries,

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

6 FAQs about [Flywheel energy storage should be AC or DC]

Are flywheel energy storage systems environmentally friendly?

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage and release, high power density, and long-term lifespan. These attributes make FESS suitable for integration into power systems in a wide range of applications.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

How much energy does a flywheel store?

Indeed, the development of high strength, low-density carbon fiber composites (CFCs) in the 1970s generated renewed interest in flywheel energy storage. Based on design strengths typically used in commercial flywheels, σmax /ρ is around 600 kNm/kg for CFC, whereas for wrought flywheel steels, it is around 75 kNm/kg.

What is a flywheel energy storage unit?

A flywheel energy storage unit is a mechanical system designed to store and release energy efficiently. It consists of a high-momentum flywheel, precision bearings, a vacuum or low-pressure enclosure to minimize energy losses due to friction and air resistance, a motor/generator for energy conversion, and a sophisticated control system.

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

What is the difference between flywheel and battery energy storage system?

Compared to battery energy storage system, flywheel excels in providing rapid response times, making them highly effective in managing sudden frequency fluctuations, while battery energy storage system, with its ability to store large amounts of energy, offers sustained response, maintaining stability .

Learn More

- Supercapacitor flywheel energy storage

- What does flywheel energy storage frequency regulation mean

- Flywheel energy storage magnification

- Huawei flywheel energy storage unit flexibility

- Communication base station flywheel energy storage 19

- Pros and Cons of Home Flywheel Energy Storage

- New energy storage flywheel

- Energy storage flywheel 2971186Z space

- Flywheel Energy Storage Payback Cycle

Industrial & Commercial Energy Storage Market Growth

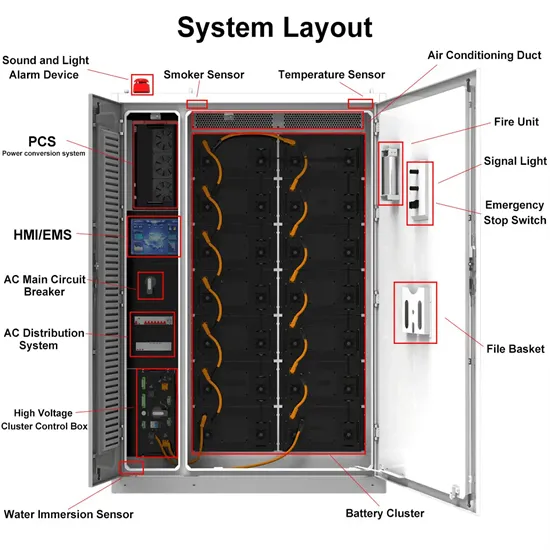

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

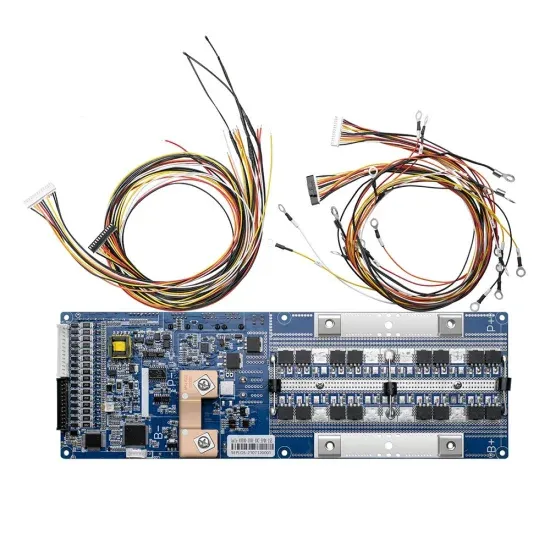

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.