Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy storage (FESS),

China''s First Shared Energy Storage Demonstration Project

Apr 1, 2025 · This marks the first domestic shared storage demonstration project to integrate four types of new energy storage technologies—lithium iron phosphate, sodium-ion, vanadium

Energy Storage System Products List | HUAWEI Smart PV

Energy Storage System Products List covers all Smart String ESS products, including LUNA2000, STS-6000K, JUPITER-9000K, Management System and other accessories product series.

Research Progress of Flywheel Energy Storage Technology

To study the method to improve the flexibility of the unit, this paper introduces the flywheel energy storage technology and the related research of the coupled generator set in detail.

A cross-entropy-based synergy method for capacity

Feb 1, 2025 · • Proposed a cross-entropy-based synergy method for flywheel energy storage capacity configuration and SOC management. • Enhanced the stability of flywheel-thermal

Flywheel Energy Storage PCS: The Secret Sauce for Modern Grid Flexibility

Why Your Grid Needs a Mechanical Marathon Runner (Hint: It''s Not a Hamster Wheel) Imagine a 10-ton steel rotor spinning at 16,000 RPM in a vacuum chamber – that''s your modern flywheel

Analysis of the improvement in the regulating capacity of thermal power

Mar 1, 2025 · Abstract The share of renewable energy in new power systems is on the rise, necessitating rapid load adjustments by thermal power units (TPUs) to maintain renewable

Flexibility improvement method of coal-fired thermal power

Jan 15, 2022 · However, the coal-fired power unit load regulation capacity requires significant improvement. Based on the energy storage characteristics of the coal-fired power unit, a load

Exploring Flywheel Energy Storage Systems and

Aug 18, 2025 · Overall, the operating principles of flywheel technology underscore its potential as a robust energy solution. By mastering kinetic energy storage,

Energy Storage Flywheel Market – PW Consulting Chemical & Energy

Jan 24, 2025 · Energy storage flywheel systems are gaining traction due to their ability to deliver rapid energy discharge, high cycle life, and minimal environmental impact. Renewable energy

Analysis of the improvement in the regulating capacity of thermal power

Mar 1, 2025 · The share of renewable energy in new power systems is on the rise, necessitating rapid load adjustments by thermal power units (TPUs) to maintain renewable energy grid

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Huawei Digital Power''s All-Scenario Grid Forming ESS

May 15, 2025 · Huawei''s Smart String Grid Forming ESS gleans more value from energy storage through power electronics technology, as well as ensuring grid safety and stability through

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · There are two objectives in implementing multi-unit array controls: maintaining a stable balance of power among units so that maximum site power can be achieved without

Simulation and evaluation of flexible enhancement of

Jun 23, 2023 · An innovative approach to enhance the flexibility of the conventional thermal power unit (TPU) through the utilization of flywheel energy storage array (FESA) is presented,

Renewable Energy Sources Integration with Flywheel Energy Storage

Dec 24, 2022 · The incorporation of flywheel energy storage system (FESS) is related to competing technologies, in this article. High charge-power may be given while the syste

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

Empowering Renewables: The Pivotal Role and

Apr 6, 2024 · Flywheel energy storage involves spinning a wheel at high speeds and extracting the energy through deceleration. Each of these systems possesses unique advantages

Research Progress of Flywheel Energy Storage Technology

To study the method to improve the flexibility of the unit, this paper introduces the flywheel energy storage technology and the related research of the coupled generator set in detail.

6 FAQs about [Huawei flywheel energy storage unit flexibility]

Are flywheel energy storage systems environmentally friendly?

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage and release, high power density, and long-term lifespan. These attributes make FESS suitable for integration into power systems in a wide range of applications.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

What is a flywheel energy storage unit?

A flywheel energy storage unit is a mechanical system designed to store and release energy efficiently. It consists of a high-momentum flywheel, precision bearings, a vacuum or low-pressure enclosure to minimize energy losses due to friction and air resistance, a motor/generator for energy conversion, and a sophisticated control system.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What is the difference between flywheel and battery energy storage system?

Compared to battery energy storage system, flywheel excels in providing rapid response times, making them highly effective in managing sudden frequency fluctuations, while battery energy storage system, with its ability to store large amounts of energy, offers sustained response, maintaining stability .

Learn More

- Flywheel energy storage manufacturing unit

- Huawei flywheel energy storage products

- Huawei Nigeria Energy Storage Photovoltaic Unit

- Huawei s ultra-low temperature energy storage battery

- Huawei North Macedonia Industrial Energy Storage Cabinet Supplier

- Huawei Energy Storage Project Planning

- Huawei Jordan Energy Storage Container

- Huawei Central Asia Outdoor Energy Storage Power Supply

- Columbia Hospital Flywheel Energy Storage

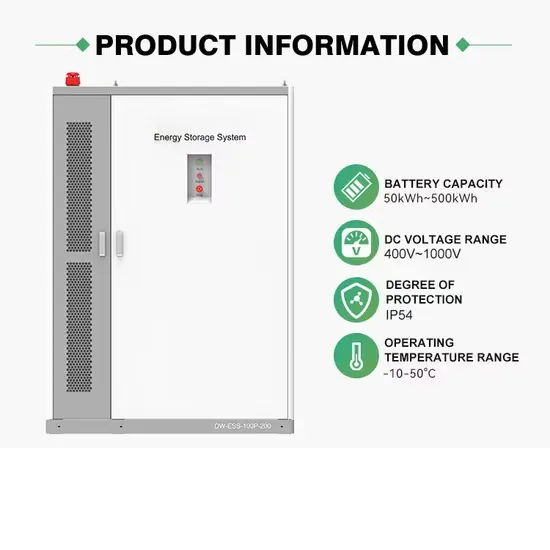

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.