Unlock the Secrets of Energy Efficiency: How Flywheels Are

Jun 30, 2025 · Flywheels can store excess energy generated by renewable sources and release it as needed to stabilize the grid. This helps mitigate the intermittency of solar and wind power,

Columbia thermoelectric flywheel energy storage

Thermal energy storage is predicted to triple in size by 2030. Mechanical energy storage harnesses motion or Page 1/3 Columbia thermoelectric flywheel energy storage gravity to

Flywheel energy storage

Oct 28, 2015 · Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy. When energy is

Flywheels | Climate Technology Centre & Network | Tue,

Aug 12, 2025 · Components of a flywheel energy storage system A flywheel has several critical components. a) Rotor – a spinning mass that stores energy in the form of momentum (EPRI,

Energy and environmental footprints of flywheels for utility

Jan 1, 2021 · The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

Flywheel Energy Storage: Alternative to Battery

Oct 5, 2024 · As the energy grid evolves, storage solutions that can efficiently balance the generation and demand of renewable energy sources are critical.

Flywheel energy storage systems and their application with

Nov 18, 2021 · The rising demand for continuous and clean electricity supply using renewable energy sources, uninterrupted power supply to responsible consumers and an increas

Energy Storage Flywheel Market – PW Consulting Chemical & Energy

Jan 24, 2025 · Energy storage flywheel systems are gaining traction due to their ability to deliver rapid energy discharge, high cycle life, and minimal environmental impact. Renewable energy

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Hospital Finds Success With Flywheel-Based Energy Storage

Jul 12, 2006 · Meriter Hospital has ordered three additional Pentadyne VSS+DC flywheel systems to protect the hospital''s sensitive medical diagnostic equipment from power outages.

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

A Review of Flywheel Energy Storage System Technologies

Flywheels have attributes of a high cycle life, long operational life, high round-trip efficiency, high power density, low environmental impact, and can store megajoule (MJ) levels of energy with

Hospital Taps Kinetic Flywheel Technology For Backup Power

Dec 16, 2014 · The kinetic energy storage flywheel functions similar to an active mechanical battery that supplies kinetic energy by rotating a mass around an axis. Electrical input rotates

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Technology could boost renewable energy storage

Sep 16, 2024 · Technology could boost renewable energy storage Columbia Engineers develop new powerful battery ''fuel'' -- an electrolyte that not only lasts longer but is also cheaper to

World''s Largest Flywheel Energy Storage System

May 17, 2020 · Since there is very little friction, the flywheel spins continually with very little added energy input needed. Energy can then be drawn from the

Flywheel and Google Partner to Deliver Industry''s First Cloud

Jul 12, 2018 · We are fortunate Flywheel is a leading medical imaging informatics platform for researchers that''s transforming the way research is conducted in academia, clinics and

Industrial Solutions Flywheel UPS Systems, 50-1000 kVA

Dec 27, 2021 · How the Flywheel Works The flywheel energy storage system works like a dynamic battery that stores energy by spinning a mass around an axis. Electrical input spins

Grid-Scale Flywheel Energy Storage Plant

Dec 7, 2012 · Flywheel systems are kinetic energy storage devices that react instantly when needed. By accelerating a cylindrical rotor (flywheel) to a very high speed and maintaining the

6 FAQs about [Columbia Hospital Flywheel Energy Storage]

What are flywheel energy storage systems?

Flywheel Energy Storage Systems present a highly effective, sustainable, and economical alternative to traditional battery storage, particularly for grid-interactive buildings. Their application in commercial properties, universities, and hospitals offers numerous benefits, including fast response times, longevity, and low environmental impact.

Can a hospital use a flywheel?

Hospitals with grid-interactive technology can integrate flywheels as a reliable, quick-response energy source. In cases of power loss, flywheels can seamlessly transfer energy to critical systems while other backup systems, such as generators, come online.

How does a flywheel store energy?

A flywheel stores energy that is based on the rotating mass principle. It is a mechanical storage device which emulates the storage of electrical energy by converting it to mechanical energy. The energy in a flywheel is stored in the form of rotational kinetic energy.

What is a flywheel used for?

The flywheel as a means of energy storage has existed for thousands of years as one of the earliest mechanical energy storage systems. For example, the potter’s wheel was used as a rotatory object using the flywheel effect to maintain its energy under its own inertia .

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Learn More

- Kampala Hospital Flywheel Energy Storage

- Columbia Power Emergency Energy Storage

- Flywheel energy storage 250kva

- Advantages and disadvantages of flywheel energy storage UPS

- Flywheel energy storage disc material

- How to build a flywheel energy storage project for a communication base station

- FPGA flywheel energy storage

- Libya flywheel energy storage system

- Abkhazia Flywheel Energy Storage Company

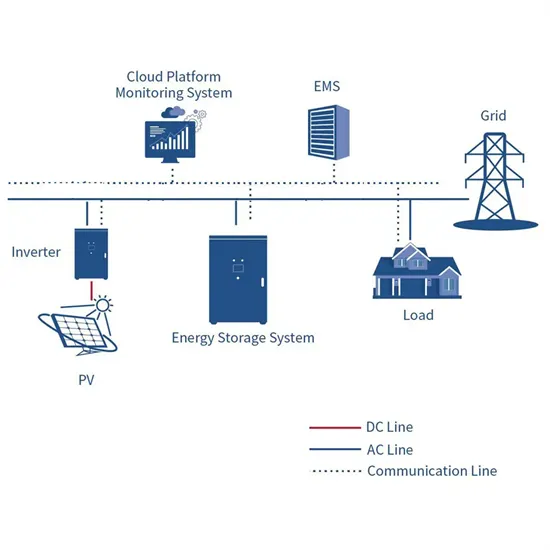

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.