Energy storage advantages and disadvantages

The negative environmental impacts of conventional power generation have resulted in increased interest in the use of renewable energy sources to produce electricity. However, the main

The Unexpected Result From Our Analysis of Battery Versus Flywheel UPS

Apr 21, 2015 · Of course, the tool lets users conduct their own comparison to see for themselves. This analysis and tool are a good reminder that decisions around energy storage needs to

Evaluating the Advantages and Disadvantages of Using

Aug 18, 2021 · Here are some advantages and disadvantages of using ultracapacitors for energy storage: Advantages High power density: Ultracapacitors have a relatively high power density,

Comparing the Characteristics of Flywheel and Battery Energy Storage

Oct 13, 2021 · In recent years, flywheel and battery ESS have emerged as two popular options for energy storage technologies. In this article, we''ll compare the characteristics of flywheel and

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Flywheel UPS – the pros and cons

Oct 9, 2012 · Flywheel UPS – the pros and cons General Manager of Riello UPS, Robin Koffler discusses flywheel UPS systems and the pros and cons of this emerging technology Rising

Flywheel ES Advantages vs Disadvantages Analysis

Sep 14, 2024 · Advantages and Disadvantages of Flywheel Energy Storage: Flywheel energy storage is a promising technology that has several advantages and disadvantages. Here we

DESIGN AND ANALYSIS OF FLYWHEEL ENERGY

Aug 4, 2016 · Abstract: Energy can be stored in the form of chemical, thermal, electromagnetic and mechanical form. The applications of mechanical energy storage devices include

Flywheel Energy Storage: Alternative to Battery

Oct 5, 2024 · As the energy grid evolves, storage solutions that can efficiently balance the generation and demand of renewable energy sources are critical.

WHAT ARE THE ADVANTAGES AND DISADVANTAGES OF A FLYWHEEL ENERGY STORAGE

Flywheel energy storage is a form of mechanical energy storage that works by spinning a rotor (flywheel) at very high speeds. This stored energy can be quickly converted back to electricity

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · 00-01 99-00 Keywords: and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage. Fly wheels store energy in mechanical rotational

Disadvantages of flywheel energy storage system

Advantages of Flywheel Energy Storage: High Power Density:FES has a very high power density,meaning it can quickly deliver much energy. This makes it suitable for applications that

6 FAQs about [Advantages and disadvantages of flywheel energy storage UPS]

What are the advantages of a flywheel system?

Flywheel systems have several advantages, particularly in applications requiring fast charge and discharge cycles. Rapid Charge/Discharge: Flywheels can charge and discharge electricity much faster than traditional batteries, making them ideal for balancing power grids or managing short-term fluctuations in energy demand.

What are the disadvantages of Flywheel energy storage systems?

However, flywheel energy storage systems also have some disadvantages. One of the main challenges of flywheel systems is friction loss, which can cause energy loss and reduce efficiency. This means that flywheels require regular maintenance to minimize energy loss due to friction.

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

How efficient is a flywheel energy storage system?

Flywheel energy storage systems are highly efficient, with energy conversion efficiencies ranging from 70% to 90%. However, the efficiency of a flywheel system can be affected by friction loss and other energy losses, such as those caused by the generator or motor.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Learn More

- Advantages and disadvantages of travel energy storage power station

- Advantages and disadvantages of Huawei s dynamic energy storage battery

- Lithium-ion battery energy storage advantages and disadvantages

- Advantages and disadvantages of energy storage battery vehicles

- Advantages and disadvantages of tension energy storage device

- Advantages and disadvantages of capacitors and battery energy storage

- Advantages and disadvantages of compressed wind energy storage power station

- Columbia Hospital Flywheel Energy Storage

- Obstructing communication base station flywheel energy storage

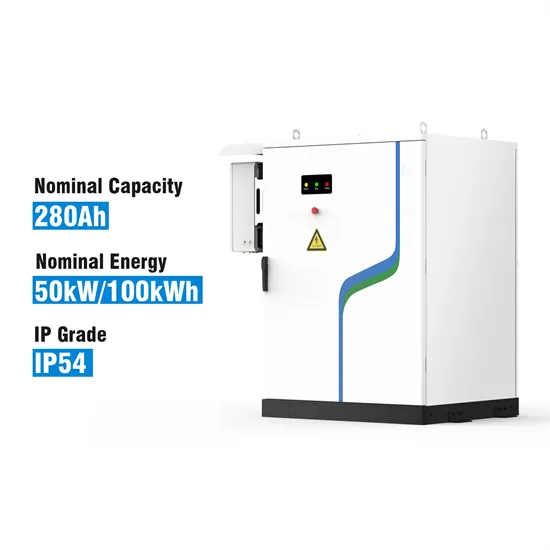

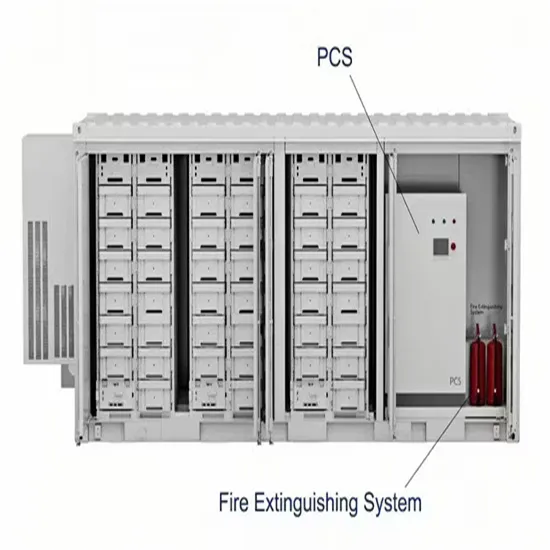

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.