The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheels store rotational kinetic energy in the form of a spinning cylinder or disc, then use this stored kinetic energy to regenerate electricity at a later time. The amount of

Development of a High Specific Energy Flywheel Module,

Aug 6, 2020 · a rapidly spinning wheel - with 50 times the Storage capacity of a lead-acid battery As the flywheel is discharged and spun down, the stored rotational energy is transferred back

A cross-entropy-based synergy method for capacity configuration

Feb 1, 2025 · Abstract Energy storage systems, coupled with power sources, are applied as an important means of frequency regulation support for large-scale grid connection of new

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

principle of flywheel energy storage power station

A novel capacity configuration method of flywheel energy storage A large capacity flywheel energy storage device equipped in DC-FCS is discussed in [19], and a method of energy

Hybrid energy storage configuration method for wind power

Feb 1, 2024 · Finally, based on the hour-level wind energy stable power curves, we carry out two-stage robust planning for the equipment capacity of low-frequency cold storage tanks and

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Research on the application of flywheel energy storage

This article explains the capacity configuration method of flywheel energy storage devices for existing and new lines, considering factors such as space limitations in traction stations, the

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

20 MW Flywheel Energy Storage Plant

Oct 15, 2014 · Beacon Power – fourth largest deployed ES capacity in 3Q 2013* 5 *excluding traditional pumped storage, CAES and solar thermal, Navigant Research "Stationary Storage

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Optimal sizing and energy management strategy for EV

Jun 1, 2023 · Power grid is assumed to intervene in order to fill the gap of energy left between the charging station load and the PV generation and flywheel energy storage system as depicted

Flywheel Energy Storage System Basics

Aug 13, 2025 · Flywheels can store grid energy up to several tens of megawatts. If we had enough of them, we could use them to stabilize power grids. Batteries also started out as small

Dual‐inertia flywheel energy storage system for electric

Aug 30, 2024 · Abstract Managing the high-rate-power transients of Electric Vehicles (EVs) in a drive cycle is of great importance from the battery health and drive range aspects. This can be

Optimal capacity configuration and operation strategy of

Nov 1, 2024 · Load agents need to compare different energy storage options in different power markets and energy storage trading market scenarios, so that they can maximize economic

A cross-entropy-based synergy method for capacity configuration

Request PDF | On Jan 1, 2025, Feng Hong and others published A cross-entropy-based synergy method for capacity configuration and SOC management of flywheel energy storage in primary

State switch control of magnetically suspended flywheel energy storage

Jan 27, 2025 · The magnetically suspended flywheel energy storage system (MS-FESS) is an energy storage equipment that accomplishes the bidirectional transfer between electric energy

Augmenting electric vehicle fast charging stations with

Sep 10, 2024 · This work investigates the economic efficiency of electric vehicle fast charging stations that are augmented by battery-flywheel energy storage. Energy storage can aid fast

A novel capacity configuration method of flywheel energy storage

Jun 1, 2021 · This paper proposes a capacity configuration method of the flywheel energy storage system (FESS) in fast charging station (FCS). Firstly, the load current compensation and

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · 00-01 99-00 Keywords: and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There

Primary frequency modulation control strategy for flywheel energy

Abstract: With the increasing integration of new energy sources, the issue of frequency stability in power systems is becoming more severe. This study proposes an improved control strategy

Power Allocation Optimization of Hybrid Energy Storage

Nov 30, 2024 · The flywheel energy storage system structure is composed of flywheel rotor, magnetic levitation bearing system, power electronic converter, motor and other main parts,

Simulation and application analysis of a hybrid energy storage station

Oct 1, 2024 · A simulation analysis was conducted to investigate their dynamic response characteristics. The advantages and disadvantages of two types of energy storage power

Research on frequency modulation capacity configuration

Dec 15, 2023 · Therefore, this paper takes the cooperative work between flywheel‑lithium battery hybrid energy storage and thermal power units as the research goal, establish a suitable

6 FAQs about [Flywheel energy storage power station configuration]

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

Are flywheel energy storage systems environmentally friendly?

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage and release, high power density, and long-term lifespan. These attributes make FESS suitable for integration into power systems in a wide range of applications.

What is a flywheel energy storage system (fess)?

According to Al-Diab (2011) the flywheel energy storage system (FESS) could be exploited beneficially in dealing with many technical issues that appear regularly in distribution grids such as voltage support, grid frequency support, power quality improvement and unbalanced load compensation.

What is a magnetically suspended flywheel energy storage system (MS-fess)?

The magnetically suspended flywheel energy storage system (MS-FESS) is an energy storage equipment that accomplishes the bidirectional transfer between electric energy and kinetic energy, and it is widely used as the power conversion unit in the uninterrupted power supply (UPS) system.

What is a flywheel energy storage unit?

A flywheel energy storage unit is a mechanical system designed to store and release energy efficiently. It consists of a high-momentum flywheel, precision bearings, a vacuum or low-pressure enclosure to minimize energy losses due to friction and air resistance, a motor/generator for energy conversion, and a sophisticated control system.

How does a flywheel energy unit work?

D. Power Electronics The flywheel energy unit produces variable frequency AC current. To reliably operate the system, power electronics devices must be installed in order to keep the frequency constant so that it can be connected to the grid. Power converters for energy storage systems are based on SCR, GTO or IGBT switches.

Learn More

- Communication base station flywheel energy storage user hybrid power supply

- Guatemala communication base station flywheel energy storage photovoltaic power generation capacity

- Optimal configuration of energy storage power station capacity

- Energy storage power station equipment configuration

- Factory energy storage power station 800kw

- Energy storage power station is suitable for several frequency regulation

- Communication base station energy storage power generation equipment

- Brunei Energy Storage Power Station Project

- Total investment return rate energy storage power station

Industrial & Commercial Energy Storage Market Growth

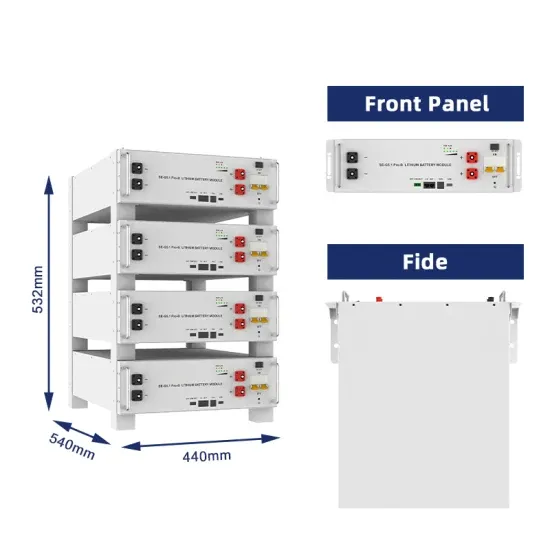

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.