Automotive Battery Pack Standards and Design

Apr 7, 2025 · Battery packs are key components of electric vehicles (EVs) because they operate as the main power supply. Despite recent advancements, further improvements are required

Design of high-voltage battery packs for electric vehicles

Jan 1, 2015 · The bottleneck of electric road vehicles lies in the low energy density, high costs, and limited lifetime of the battery cells contained in a high-voltage battery pack. As the battery

Automotive Battery Pack Standards and Design

Mar 18, 2025 · Battery packs are key components of electric vehicles (EVs) because they operate as the main power supply. Despite recent advancements, further improvements are required

Intelligent optimization methodology of battery

Jul 14, 2020 · A synthetic methodology for an advanced design of battery pack is proposed. Comprehensive recycling framework of battery and battery pack is

Automotive battery pack standards and design

Jul 1, 2025 · The latest advancements and near-future trends in automotive battery packs, underlying regulatory compliance, and performance requirements are presented in this paper.

Battery Pack Design Considerations for Performance and

1 day ago · Certifications only apply to in-house designs: Epec can only certify battery packs they design and build, as certification depends on the complete integration of the electrical system

Design approach for electric vehicle battery packs based on

Jan 30, 2024 · This work proposes a multi-domain modelling methodology to support the design of new battery packs for automotive applications. The methodology allows electro-thermal

Brochure for Battery Pack Desgin and Devempment

Aug 8, 2025 · Learn how to design eicient electrical connections in a batery pack. Optimizing electrical pathways for reduced resistance and improved thermal stability. Provides an

Brochure for Battery Pack Desgin and Devempment

Aug 8, 2025 · BATTERY PACK DESIGN AND DEVELOPMENT: FUNDAMENTALS About the program: The rapid electrification of transportation is transforming how we design and develop

Battery Development for Electric Vehicles

4 days ago · McLaren Speedtail Battery pack development project from initial concept to start of production (SOP), incorporating modules into the battery pack for hybrid electric vehicle. The

Methodology and Application of Electric Vehicles Battery Packs

Jan 1, 2020 · Li-Ion packs are high added-value products with great amounts of critical materials (e.g. Lithium and Cobalt), therefore an effective circular economy strategy is mandatory for

Fundamentals of Electric Vehicle Battery Pack Design

Dec 24, 2024 · This NOS unit is about designing EV battery pack in sustainable-optimal-durable-economical manner. Its as well about skilling on designing, analyzing, validating, maintaining

EV Lithium Battery PACK Design Process from Manufacturers

Mar 18, 2025 · At Bonnen Battery, our engineering team follows a systematic approach to battery pack design, ensuring optimal performance and safety for various EV applications. This blog

Introduction to Electric Vehicle Battery Modules and Packs

4 days ago · 12V battery packs for accessories 12V battery packs provide power to low energy accessories and applications in a vehicle, such as headlights and radio. How EV battery packs

Designing better batteries for electric vehicles

Aug 16, 2021 · Large, heavy battery packs take up space and increase a vehicle''s overall weight, reducing fuel efficiency. But it''s proving difficult to make today''s

Automotive Battery Pack Standards and Design

Mar 18, 2025 · The electrical specifications of the battery pack as the source of traction energy and power are explained in this section. The battery pack should be able to provide the

Development of Formula Student Electric Car Battery Design

Jan 1, 2016 · One of the most important parts of a Formula Student Electric race car is a battery pack, which includes accumulators and a battery management system. Difficult operating

6 FAQs about [Battery pack electrical development]

What is battery pack development?

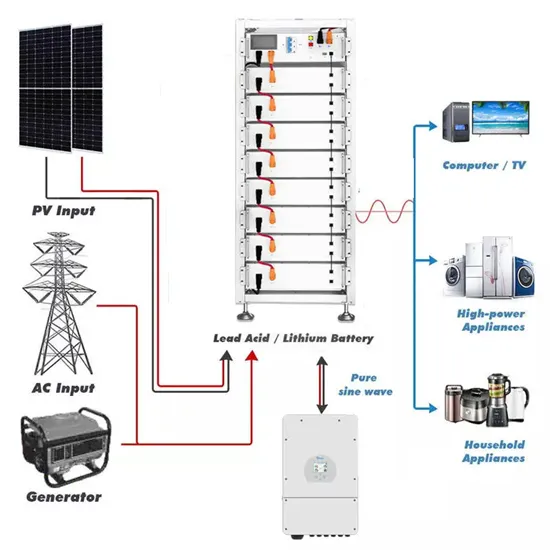

As electric vehicles (EVs) revolutionize mobility, battery pack development stands at the forefront of this transition. Original Equipment Manufacturers (OEMs) now strive for deeper control over the value chain, from Battery Management Systems (BMS) to fundamental design capabilities.

How to design a battery pack?

The dimensions of battery packs also require a design to space evaluation. The occupied volume of the pack should be suitable for the related car chassis. As previously mentioned in Section 1, CTP and CTC are two different strategies for packaging design. These approaches differ from the modular one.

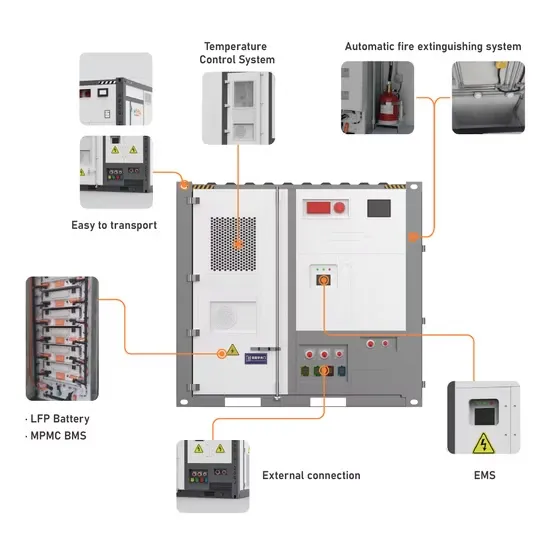

How can battery packaging design improve battery safety?

A robust and strategic battery packaging design should also address these issues, including thermal runaway, vibration isolation, and crash safety at the cell and pack level. Therefore, battery safety needs to be evaluated using a multi-disciplinary approach.

How do you design a custom lithium battery pack?

This blog post outlines the comprehensive design process we follow when developing custom lithium battery packs for our clients. The first and foundational step in battery pack design is a thorough analysis of requirements and specification definition. This initial phase sets the direction for the entire design process.

What is the first step in battery pack design?

The first and foundational step in battery pack design is a thorough analysis of requirements and specification definition. This initial phase sets the direction for the entire design process. During this stage, our engineering team works closely with clients to determine key parameters based on the specific application needs.

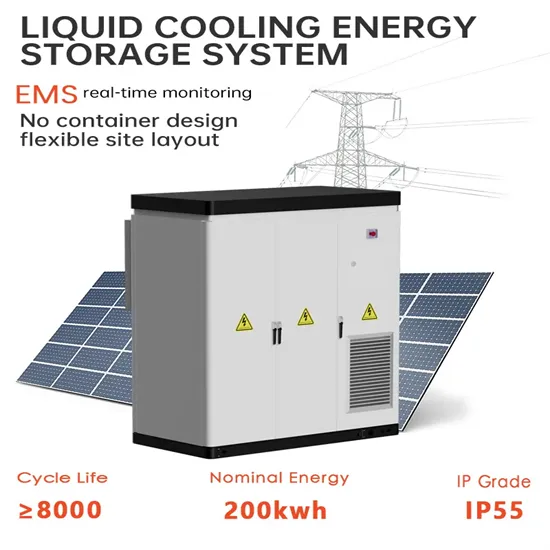

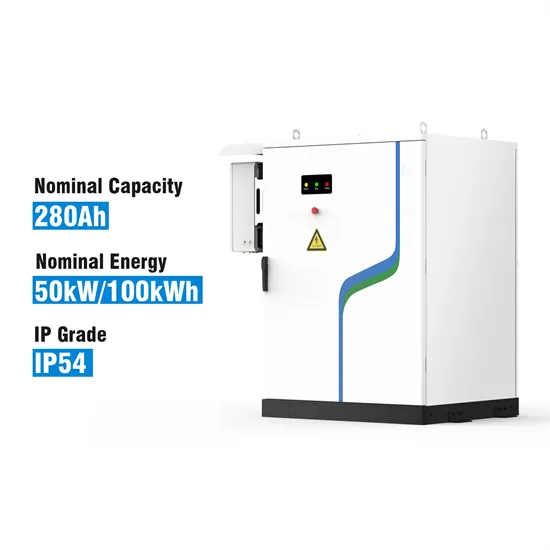

What is liquid cooled battery pack design?

Liquid-cooled battery pack design is increasingly requiring a design study that integrates energy consumption and efficiency, without omitting an assessment of weight and safety hazards.

Learn More

- Battery pack typical electrical price

- Pack processed battery

- Layoune RV modified lithium battery pack

- New lithium battery pack virtual power

- Lithium battery pack serial charging

- Vienna lithium battery pack

- Outdoor energy storage lithium battery pack

- Battery pack factory construction plan

- Battery Pack product design

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.