ISO/TS 21480:2021

Jul 9, 2024 · 6.22 complete dismantled system The dismantlement of photovoltaic insulating glass units with PV power generation should avoid should be recorded the transportation and into

The Height of Photovoltaic Panel Transport Tracks: Why

The height of photovoltaic panel transport tracks has become the unsung hero of solar farm installations, determining whether your $2 million shipment arrives ready for installation or

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting

Investigation of static and dynamic mechanical loads on light-weight PV

Nov 15, 2024 · The findings indicate that a low inclination installation is preferable, and a glass-glass PV module with a 2.5 mm glass thickness can withstand static and dynamic mechanical

Texturized glass in the application of architectural

Oct 1, 2024 · Structural glass has been found to have a significant impact on cooling photovoltaic modules (Duell et al., 2010). Verma et al., (2011) and other authors created randomly

Review of issues and opportunities for glass supply for photovoltaic

The rapid expansion of PV manufacturing necessitates a substantial amount of glass, with forecasts suggesting consumption ranging from 64–259 million tonnes (Mt) and 122–215 Mt by

Photovoltaic glass transportation measures

Are glass-glass PV modules a problem? Unfortunately, glass-glass PV modules are, similar to regular PV modules, subject to early life failures. A failure of growing concern are defects in

Improvement Options for PV Modules by Glass Structuring

Sep 20, 2023 · We found that when a structured glass surface is present at the solar module''s front, an increase in electricity yield can be achieved, with the largest gains under angles of

Visual and energy optimization of semi-transparent

The levelized cost of electricity (LCOE) generated by the hybrid installation of low-e glass and PV curtain wall was 0.894/kWh when the surrounding buildings were shaded, which was better

Optimizing Photovoltaic Panel Transportation Routes:

Why Photovoltaic Panel Transportation Routes Demand Specialized Attention Did you know that 23% of solar project delays in 2024 were linked to transportation issues? Photovoltaic (PV)

NGA Presents Updated Resource on Glass Properties

Mar 28, 2025 · NGA has published an updated Glass Technical Paper (GTP), FB39-25 Glass Properties Pertaining to Photovoltaic Applications, which is available for free download in the

Packaging Datasheet1

Jan 9, 2025 · The height of the unloading platform and the height of the unloading tooling should be kept at the basic level with the bottom of the container (loading bottom plate), and the

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · A failure of growing importance is the defect in the glass layer (s) of glass-glass PV modules. In this research, an experimental glass repair technique for glass-glass PV modules

Photovoltaic windows cut energy use and CO

Nov 18, 2022 · For glass façades in particular, thin-film PV glazing makes sense because the single most expensive component of the technology is the glass, 63 a component that will be

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · •Glass can: – increase module efficiency – improve mechanical reliability – improve electrical isolation performance – improve module durability – decrease module weight

Review of degradation and failure phenomena in photovoltaic

May 1, 2022 · Secondly, a summary of the main stress factors and how they influence module degradation. Finally, a detailed review of degradation and failure modes, which has been

A review on photovoltaic combined vacuum glazing: Recent

May 1, 2023 · Recently, PV combined vacuum glazing has become a popular research topic and attracted researchers to resolve the drawbacks of commonly used glazing products. In the last

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

Advancements in Photovoltaic Glass Technology

Aug 19, 2025 · Photovoltaic glass integration in factoriesPhotovoltaic glass integration transforms factory roofs and walls into power-generating assets while maintaining structural integrity and

STORAGE AND UNPACKING INSTRUCTION OF

Jan 9, 2025 · The height of the unloading platform and the height of the unloading tooling should be kept at the basic level with the bottom of the container (loading bottom plate), and the

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

JA Solar PV Single-glass Modules Installation Manual

Jan 8, 2025 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules. This Manual

Synergistic optimization analysis of droplet cleaning

Jul 1, 2025 · These findings provide actionable guidelines for designing the next generation of water-saving photovoltaic self-cleaning systems. There are two major innovations in this

6 FAQs about [Photovoltaic glass transportation component height]

Can SLS glass be used in PV modules?

SLS glass is ubiquitous for architectural and mobility applications; however, in terms of its application in PV modules, there remains room for improvement. In the current paper, we have reviewed the state of the art and conclude that improvements to PV modules can be made by optimizing the cover glass composition.

How much does a solar module weigh?

Typical dimensions of a domestic PV module are 1.4–1.7 m 2, with >90% covered by soda–lime–silica (SLS) float glass. 9 The glass alone weighs ~20–25 kg since the density of SLS glass is ~2520 kg/m 3. This presents engineering challenges as current solar panels are rigid and need strong, heavy support structures.

Does flat glass improve photovoltaic (PV) panel efficiency?

Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36]. Based on in-depth analyses of market size, trends, and growth projections. Table 1. Flat glass market. augmented reality and advanced display technologies.

How do compositional changes affect the life of PV modules?

The compound effect of these compositional changes to the cover glass thereby enables both increased efficiency and increased lifetime of PV modules. This was also demonstrated for laboratory-scale PV modules in terms of measured Isc and Ipm; however, further measurements to confirm the results are advisable.

Which cover material should be used for PV modules?

Currently, 3-mm-thick glass is the predominant cover material for PV modules, accounting for 10%–25% of the total cost. Here, we review the state-of-the-art of cover glasses for PV modules and present our recent results for improvement of the glass.

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

Learn More

- New Energy Photovoltaic Power Generation Glass Component Lamination

- Abu Dhabi non-standard photovoltaic glass component research and development

- Photovoltaic glass curtain wall function

- Montevideo Sun Room Photovoltaic Glass Price

- Is photovoltaic power generation made of glass

- Which company has photovoltaic glass in Comoros

- How much does 2mm photovoltaic glass cost

- Solar photovoltaic transparent glass

- The importance of glass in the photovoltaic industry

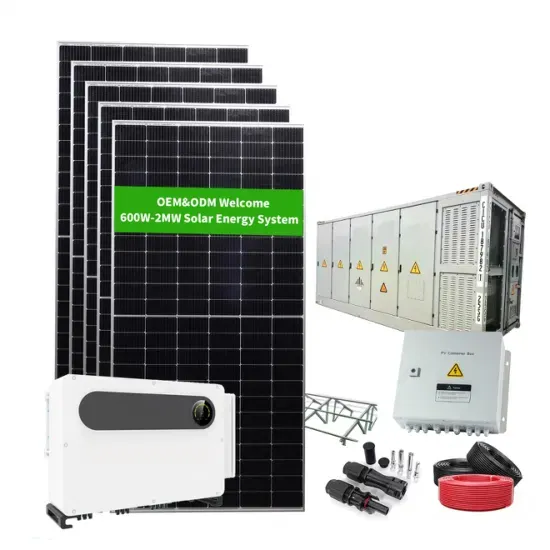

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

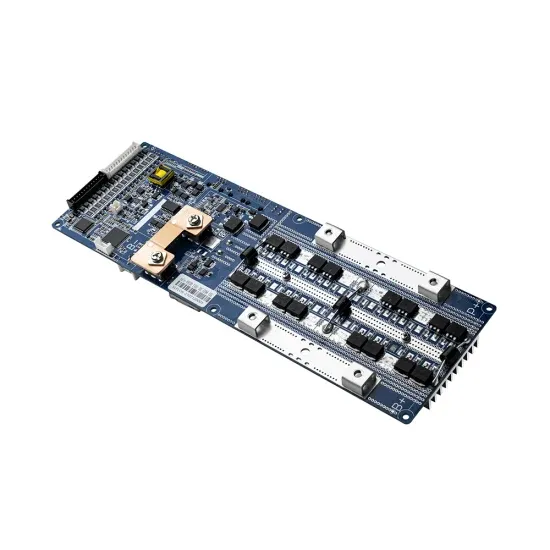

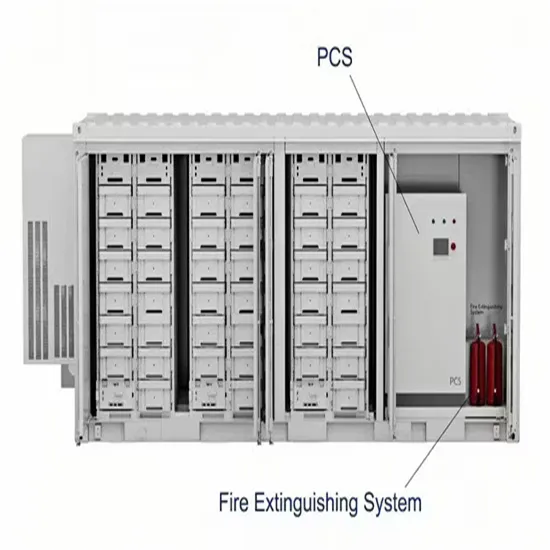

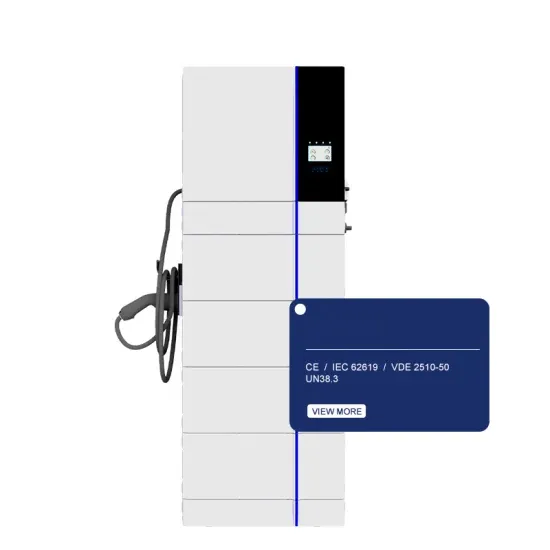

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.