Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating solar cells, and has related

China Fully Automatic Solar Module Laminator, Automatic

As a dozen years experienced technical team especially for solar module laminators, we can do the effective laminating area within 12500mm*2900mm, cover all different kinds of solar

Review of degradation and failure phenomena in photovoltaic

May 1, 2022 · The role of packaging in photovoltaic energy generation is generally underestimated, as it does not play an active role in the power generation itself. However, the

Comprehensive study on photovoltaic cell''s generation and

Feb 19, 2025 · The utilization of fossil fuels for power generation results in the production of a greater quantity of pollutants and greenhouse gases, which exerts detrimental impacts on the

A study on the microstructure and power generation

Dec 1, 2024 · The need for greenhouse gas reduction and carbon neutrality is increasing, and the Building Integrated Photovoltaic (BIPV) power generation system is emerging as a key

Thermal Modelling of Photovoltaic Modules in

Jun 6, 2024 · ABSTRACT: The temperature of solar cells in photovoltaic modules has a major influence on module power. The module setup, the material structure and the material

What does solar lamination mean? | NenPower

Oct 5, 2024 · The lamination itself is performed by sandwiching the photovoltaic cells between layers of protective materials. Commonly used materials, such as EVA, provide a transparent

Texturized glass in the application of architectural

Oct 1, 2024 · The measurements carried out show that the use of glass with a textured surface slightly reduces the electrical parameters of the PV system: around 5% for power (W) while

Laminators for the production of solar modules

The fastest two-stage lamination process for glass-glass modules and glass backsheet modules is based on a vacuum membrane press in the first step and concludes lamination with a flat

Lamination process and encapsulation materials

Mar 10, 2015 · Thermoplastic polyolefin encapsulants with water absorption less than 0.1% and no (or few) cross-linking additives have proved to be the best

Encapsulant Materials and Their Adoption in Photovoltaic

Jun 12, 2023 · In the last two decades, the continuous, ever-growing demand for energy has driven significant development in the production of photovoltaic (PV) modules. A critical issue

Double-glass solar module laminating process

Therefore, a double-glass solar panel is provided, and the photovoltaic module consisting of two pieces of glass and a battery has the following advantages: 1. the average life can be up to 30

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant

Lamination process and encapsulation materials for

May 21, 2024 · The majority of today''s crystalline silicon (c-Si) PV modules are manufactured in accordance with a glass-backsheet (GBS) module lay-up: 3.2–4mm glass at the front and a

Motivation, benefits, and challenges for new photovoltaic

May 24, 2022 · The paper aims to (1) reveal motivations and benefits for material innovations in PV, (2) to point out the challenges of new materials and new PV module designs and (3)

Lamination process and encapsulation materials for

May 21, 2024 · Lamination process and encapsulation materials for glass–glass PV module design Gianluca Cattaneo1, Antonin Faes1, Heng-Yu Li1,2, Federico Galliano1,2, Maria

Experimental assessment of lamination processing method

Mar 1, 2024 · Abstract Due to the lack of in-depth research on lamination processing methods for PV/T technology, typical flat-plate PV/T modules still face severe lifespan issues that require

Photonic microstructures for energy-generating clear glass

Aug 23, 2016 · Glass-based solar energy concentrators of high power conversion efficiency (PCE) are now expected to be deployed in next-generation windows 3, which will enable the

Analysis and solution of quality problems in photovoltaic

Apr 22, 2024 · 中步擎天新能源(湖北)有限公司component. Solution: Adjust the lamination parameters and adjust the evacuation time to adapt to the EVA reaction speed. 3.6 Bubbles in

Analysis and solution of quality problems in photovoltaic

Apr 22, 2024 · the components begin to crosslink during the lamination process, resulting in the inability to smoothly extract the gas generated during the lamination process; Solution: Adjust

Thermal-Mechanical Delamination for Recovery of Tempered Glass

Sep 4, 2024 · Abstract and Figures This paper presents a sustainable recycling process for the separation and recovery of tempered glass from end-of-life photovoltaic (PV) modules.

Multi-objective evolutionary optimization of photovoltaic glass

Nov 1, 2023 · This paper uses a genetic evolutionary optimization algorithm to explore the optimum performance of photovoltaic glass in an architecture studio regarding annual energy

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Mirrors For the generation of electricity from solar power, mirror are used to concentrate the solar light onto either photovoltaic material or a thermal receiver. Objectives The reflector should

Future of photovoltaic technologies: A comprehensive review

Oct 1, 2021 · As a result of sustained investment and continual innovation in technology, project financing, and execution, over 100 MW of new photovoltaic (PV) installation is being added to

Delamination of components for recovery of waste

Jan 15, 2025 · Using ultrasonic and heat treatment, the delamination of the glass, backsheet, and ethylene–vinyl acetate film from the solar cell was significantly accelerated. Photovoltaic

Photovoltaic solar panel double glass lamination tooling

Photovoltaic solar panel double glass lamination tooling What is the lamination process in a photovoltaic (PV) module? The lamination process is one of the most critical steps that

Experimental assessment of lamination processing method

Mar 1, 2024 · Due to the lack of in-depth research on lamination processing methods for PV/T technology, typical flat-plate PV/T modules still face severe lifespan issues that require urgent

Analysis and solution of quality problems in photovoltaic

Apr 22, 2024 · lamination process, which prevents further crosslinking reaction during the subsequent lamination process, resulting in over crosslinking between EVA and glass.

6 FAQs about [New Energy Photovoltaic Power Generation Glass Component Lamination]

What is the fastest two-stage lamination process for glass-glass modules?

The fastest two-stage lamination process for glass-glass modules and glass backsheet modules is based on a vacuum membrane press in the first step and concludes lamination with a flat press heated on both sides. Compared to the SL process, throughput times are considerably reduced, which in turn significantly increases capacity.

How are PV modules laminated?

The lamination of PV modules is most frequently carried out using a vacuum-membrane laminator with a single heating plate (Fig. 5) and a typical process based on three main steps .

What is a solar laminator?

In the laminator, the various components of the solar module are pressed and bonded together to form a durable module. In the laminator, the various components of the solar module are pressed and bonded together to form a durable module.

What is Photovoltaic Glass?

Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant current extraction devices and cables. The glass used in photovoltaic power generation is not ordinary glass, but TCO conductive glass.

What is the production process of Photovoltaic Glass?

Production process of photovoltaic glass The deep processing process of photovoltaic glass involves two steps: tempering and coating. The original sheet is ground and then tempered to obtain tempered sheets, or tempered and coated to obtain coated sheets for component packaging.

How does GG design affect PV module reliability?

This decrease in water vapour ingress has a direct positive impact on PV module reliability compared with that for a standard GBS lay-up. Recent developments of thin, 2mm tempered glass have made GG design a more competitive solution, compared with 3 or 4mm GG modules (heavyweight) or standard GBS modules.

Learn More

- Romania new energy photovoltaic power generation glass clean energy

- Photovoltaic power generation new energy and energy storage

- London New Energy Building Photovoltaic Glass Component Wholesale

- Hybrid Energy 5G Base Station Photovoltaic Power Generation System Route

- New 500W solar photovoltaic power generation for home use

- Paramaribo Photovoltaic Energy Storage Power Generation Project

- Photovoltaic power generation glass enclosed balcony

- Is photovoltaic power generation made of glass

- Mongolia New Energy Photovoltaic Module Glass

Industrial & Commercial Energy Storage Market Growth

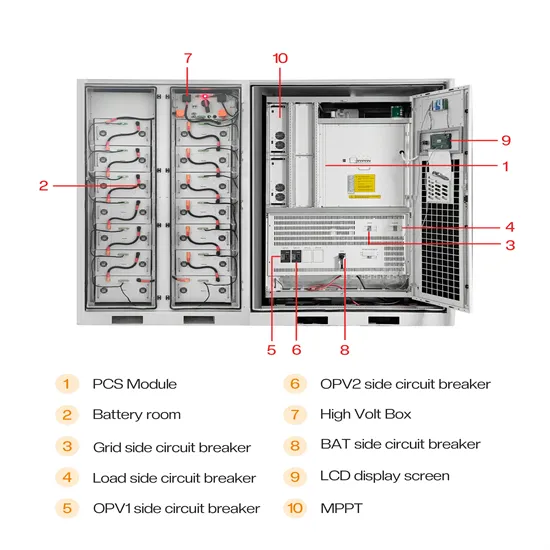

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.