The Role of Glass in 2022, and Beyond | Glass Magazine

Dec 24, 2023 · As glass technology evolves, it has allowed our industry to meet the United Nations'' 2030 SDG goals not to mention the needs of our customers, while allowing us to

Sustainable Management of Photovoltaic Waste Through

Jan 10, 2025 · The rapid expansion of photovoltaic (PV) technology as a source of renewable energy has resulted in a significant increase in PV panel waste, creating environmental and

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

An overall introduction to photovoltaic glass –

Jan 24, 2024 · In addition to solar inverter like 2000w inverter or 3000w inverter, photovoltaic glass is also an important component of the photovoltaic industry,

The importance of a Photovoltaic glass in an

Jul 1, 2022 · Picture shows in slight backlight the ''orange peel'' Photovoltaic glass includes a variety of concave or convex geometric surface elements, allowing

NGA Presents Updated Resource on Glass Properties

Mar 28, 2025 · NGA has published an updated Glass Technical Paper (GTP), FB39-25 Glass Properties Pertaining to Photovoltaic Applications, which is available for free download in the

Advancements in Photovoltaic Glass Technology

Aug 19, 2025 · Implementing PV glass technology requires careful planning, financial investment, and a willingness to adapt to new ways of operating. It is through collaboration, knowledge

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · With enormous amounts of PV modules being installed, some will be affected by early-life failures and the resulting e-waste from PV modules is raising environmental

Advanced polymer encapsulates for photovoltaic devices −

Sep 1, 2021 · Photovoltaic (PV) technology has evolved as the major renewable power resource in the worldwide green energy sector to meet the future challenge of en

Solar Glass: What Is It & What Is Its Role In Solar

Jul 22, 2021 · Performance requirements of solar glass The solar glass must have good light transmittance. Generally speaking, the light transmittance of

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

Photovoltaic Windows: Sustainable Energy Generation and

The main functions of photovoltaic windows include generating renewable energy, reducing energy consumption, and providing a sustainable alternative to traditional windows.

Glass sector deep dive: How could demand drive low

Apr 10, 2025 · 1. Introduction ive, we provide an overview of the UK glass industry value chain and production processes. This deep dive examines the most viable decarbonisation

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · The photovoltaic industry is developing rapidly to support the net-zero energy transition. Among various photovoltaic technologies, silicon-based technology is the most

Solar Photovoltaic Glass Market Size & Forecast

Feb 13, 2025 · Solar Photovoltaic Glass Market is projected to reach USD 27.3 billion by 2028. Report provides crucial industry insights that will help your

Solar Glass: applications and comparison to Light-Trapping

Solar Glass is one of the crucial barriers of traditional solar panels protecting solar cells against harmful external factors, such as water, vapor, and dirt. For what type of solar panels is glass

What is the solar glass panel industry | NenPower

Apr 18, 2024 · Innovations in glass coating technologies and improved cell arrangements have propelled the efficiency rates of photovoltaic panels, while reducing costs. Moreover, the

Exploring the Benefits of Photovoltaic Solar Glass: A Case Study

Jun 7, 2025 · As a family-owned business rooted in Las Vegas since 1953, we know the importance of craftsmanship and innovation. Our customers have always appreciated our

An Overview of the Photovoltaic Industry Status and

Dec 13, 2019 · Then it expounds the evolution of PV module technology, inverter technology and System design technology, and analyzes the development status of photovoltaic industry

NGA Presents Updated Resource on Glass Properties

Mar 28, 2025 · This paper is intended to assist both the glass fabricator and end user by providing an overview of the most important properties pertaining to glass used in photovoltaic applications.

Quartz Glass Advantages: Key Benefits for Solar Photovoltaic Industry

From wafer production to solar module encapsulation, quartz glass enables efficiency, durability, and long-term performance. This article explores how quartz glass supports every stage of

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

6 FAQs about [The importance of glass in the photovoltaic industry]

Why is Solar Photovoltaic Glass so popular?

With global attention on environmental protection and energy efficiency steadily rising, the demand for solar photovoltaic glass in both commercial and residential construction sectors has significantly increased. The desire to reduce energy costs and carbon footprint has driven the widespread adoption of solar photovoltaic glass.

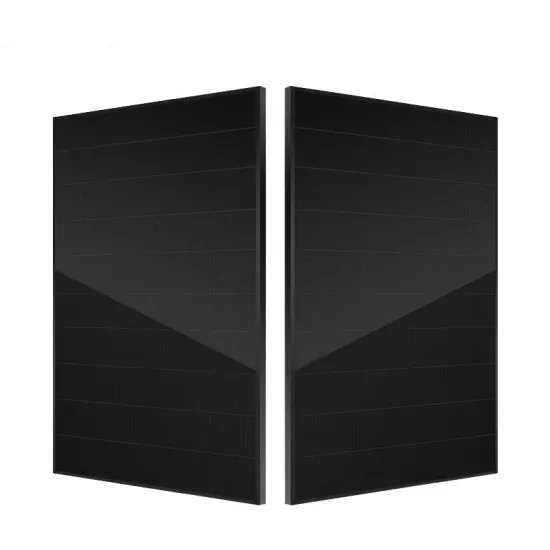

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

How does Photovoltaic Glass impact the future of manufacturing?

As the world continues to prioritize sustainability and combat climate change, the role of photovoltaic glass in shaping the future of manufacturing becomes increasingly prominent. The integration of PV glass into factory infrastructure aligns with the growing emphasis on renewable energy, energy efficiency, and green building practices.

Why is PV glass important in manufacturing?

Integrating PV glass into factory design enables manufacturing facilities to optimize energy consumption by leveraging both passive and active properties. The insulating characteristics of PV glass help maintain stable indoor temperatures, reducing the energy required for heating and cooling.

Can glass be used for solar energy?

The initial development and utilization of solar cells using glass, soon gained attention from countries like the United States and Japan, thereby accelerating the research, development, and application of low-iron, ultra-thin glass for solar energy purposes. Demand for solar photovoltaic glass has surged due to growing interest in green energy.

Why is glass used in PV cells?

Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells. Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency.

Learn More

- Photovoltaic glass industry situation

- Slovenia Coal Industry Photovoltaic Glass

- Energy efficiency standards for photovoltaic glass industry

- Indonesia s largest photovoltaic glass company

- The impact of Bhutan s photovoltaic glass production reduction on

- Huawei World Photovoltaic Glass

- Photovoltaic glass by tile

- Huawei photovoltaic module ultra-hard glass

- Glass photovoltaic structure design

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.