In Stock 2 cell pack 8.4V Lithium Ion Battery

43 rows · Mar 5, 2025 · Lithium-Ion Battery Chargers for OEMs, engineers, hobbyists and consumers. This battery charger is a microprocessor controlled

Understanding the 2 Cell Battery: What It Means and Its

Mar 25, 2025 · What is a 2 Cell Battery? A 2 cell battery primarily refers to a battery pack that consists of two individual cells. Each cell within this battery provides a nominal voltage, with a

Lithium Battery Basics: A Crash Course

Apr 29, 2021 · What is the difference between a cell and a module? What is form factor? And why is it handy to know about C-rate? Regardless of whether you''re considering a career at a

Buy Best Quality 2s lithium-ion battery with

5 days ago · These battery packs consist of two 3.7V lithium-ion cells connected in series, delivering a total voltage range of 7.4V to 8.4V. With their compact

Understanding Lithium Battery Configurations:

Apr 18, 2025 · Discover the different types of lithium battery cells, their configurations, and practical applications to create efficient and reliable energy

How to Balance Lithium Batteries with Parallel

Sep 1, 2023 · Parallel Cells vs. Strings in Parallel When designing a lithium battery pack, engineers have two primary options: connecting individual cells

Management of imbalances in parallel-connected lithium-ion battery

Aug 1, 2019 · Uneven electrical current distribution in a parallel-connected lithium-ion battery pack can result in different degradation rates and overcurrent issues in the cells. Understanding the

2S LiPo Battery: A Comprehensive Guide for

May 17, 2024 · The "2S" in a 2S LiPo battery stands for "2 Series." This indicates that the battery consists of two individual cells connected in series. In a series

How To Balance A Lithium Batteries and Cells

Oct 3, 2022 · A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery

Battery protectors

2 days ago · We understand performance and safety are major care-abouts for battery packs with lithium-based (li-ion and li-polymer) chemistries. That is why we design our battery protection

bq2920x Voltage Protection with Automatic Cell Balance

Jun 19, 2025 · The bq2920x device is a secondary overvoltage protection IC for 2-series cell lithium-ion battery packs that incorporates a high-accuracy precision overvoltage detection

Influence of battery cell spacing on thermal performance of

Mar 15, 2024 · Further, cell spacing of 5 mm, 3 mm, and 1 mm are examined, and maximum temperature and temperature difference are compared along with the weight and volume of

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Using the DS2786 Battery Fuel Gauge in a 2-Cell Battery Pack

The DS2786 is designed for a single-cell lithium-ion battery pack but can be easily adapted to a 2-cell pack. The circuit described in this application note adds only two integrated circuits and an

Grouping optimization of dual-system mixed lithium-ion battery pack

May 15, 2025 · Highlights • Battery packs containing two different types of lithium-ion batteries are studied • Electrochemical-thermal coupling modeling of dual-system battery packs is developed •

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · CMB''s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium),

Buy Best Quality 2s lithium-ion battery with

5 days ago · Discover our range of 2 Cell (7.4V~8.4V) lithium-ion battery packs, designed to provide reliable and consistent power for your electronic devices

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Strings, Parallel Cells, and Parallel Strings Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is

6 FAQs about [Two-cell lithium battery pack]

What is a 2 cell lithium-ion battery pack?

Discover our range of 2 Cell (7.4V~8.4V) lithium-ion battery packs, designed to provide reliable and consistent power for your electronic devices and projects. These battery packs consist of two 3.7V lithium-ion cells connected in series, delivering a total voltage range of 7.4V to 8.4V.

What is a lithium ion battery pack?

These battery packs consist of two 3.7V lithium-ion cells connected in series, delivering a total voltage range of 7.4V to 8.4V. With their compact size and high energy density, these battery packs are suitable for a wide range of applications, including RC vehicles, drones, portable electronics, and more.

What are battery cells & modules & packs?

Battery cells, modules, and packs are different stages in battery applications. In the battery pack, to safely and effectively manage hundreds of single battery cells, the cells are not randomly placed in the power battery shell but orderly according to modules and packages. The smallest unit is the battery cell. A group of cells can form a module.

What is a 2 cell battery?

Each battery cell is rated for a specific voltage, commonly 3.7 volts for lithium-ion batteries. So, a battery designated as a ‘2 cell battery’ would essentially have two cells connected in series. In a 2 cell battery configuration, both cells are connected in series, which increases the total voltage.

What is a battery pack?

They may be configured in series, parallel or a mixture of both to deliver the desired voltage, capacity, or power density. Packs are identified by cell size, number of cells, battery structure, chemistry, chargeability, capacity, and voltage rating. Lithium-Ion Battery Products - Battery Packs are in stock at Digikey.

What is a mixed chemistry battery pack?

The mixed chemistry battery pack consists of two types of battery cell with different chemistry in one battery pack. The aim being to offer the best of both chemistries: A look at the power density versus energy density graph. This shows that high power tends to be at the expense of energy.

Learn More

- Is there lithium phosphorus lithium battery pack processing in Malta

- Which lithium battery pack is cheaper in New York USA

- Montevideo 12v lithium battery pack

- 4 5v lithium battery pack

- 72200 Lithium battery pack structure

- Lithium battery pack 8s

- Shallow charge and discharge of lithium battery pack

- Expand the capacity of lithium battery pack

- Tbilisi lithium battery pack equipment

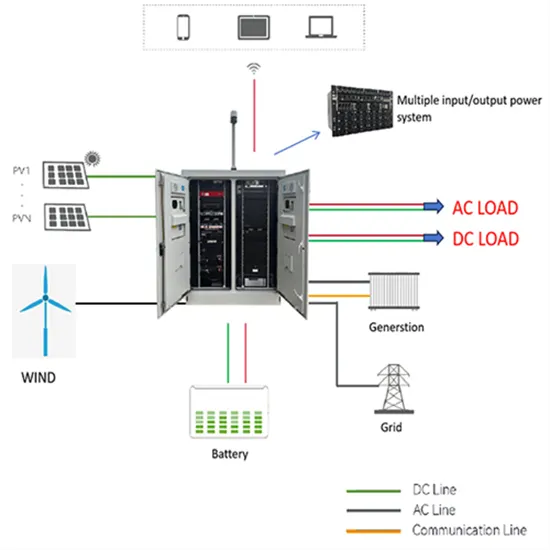

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.