Current Sensing in Battery Management Systems

Aug 10, 2023 · There are a variety of current sensing technologies that can monitor the status of an HEV or EV battery. The solution varies with the voltage and capacity of the battery. As

Why Is My Portable Power Station Not Charging

Jul 17, 2025 · How can I tell if my power station''s battery is failing versus having a charging system issue? Conduct these diagnostic tests: First, measure the battery''s open-circuit voltage

How to Measure Current of a Battery Using Multimeter? A

Jun 23, 2025 · Measuring battery current using a multimeter is a fundamental skill for anyone working with electronics or battery-powered devices. This process involves connecting the

How to achieve high precision shunt BMS battery current

Sep 21, 2023 · One of the most mature methods to achieve high accuracy and wide dynamic range shunt-based BMS battery current measurement is the use of high-resolution (ΔΣ)

Setting up a base station using AutoBase technology

Jul 23, 2025 · Setting up a base station using AutoBase technology The receiver features AutoBase™ technology, which enables you to reduce daily setup time for mobile base stations

HiPer VR Quick Reference Guide

Jul 29, 2025 · The receiver is powered by an internal battery or an external valid power source connected to the power port. If an external power source is connected, the receiver draws

Base station operation guidelines

Jul 23, 2025 · Base station operation guidelines This topic introduces the concept of base station operation, provides information to help you identify good setup locations, describes best

How To Measure Battery Current Using Multimeter?

Jun 23, 2025 · While many are familiar with using a multimeter to measure voltage or resistance, measuring current often presents a unique set of challenges and safety considerations that

How Can You Measure Battery Current Using a Multimeter?

Feb 3, 2025 · You can measure battery current using a multimeter by setting it to the ammeter function and connecting it in series with the circuit. This allows you to accurately gauge how

How to Test a Battery Current Sensor | Helpful Example (2025)

May 16, 2025 · A battery current sensor is a vital component in modern electrical systems, designed to measure and monitor the flow of electrical current in a battery. Ensuring the

Step-by-Step Battery Capacity Testing Procedure

May 23, 2024 · With our step-by-step procedure, you''ll learn how to precisely evaluate battery capacity. Discover key tools, techniques, & best practices for

4 FAQs about [How to measure the battery current of a base station]

How accurate is battery current measurement?

If you're able to accurately sense the current draw, and the battery is well-characterized, you'll be able to accurately determine the amount of time remaining before your mission-critical system dies. With careful design, you can measure battery current to within 0.2 percent of full scale.

How accurate is battery current gauging?

With careful design, you can measure battery current to within 0.2 percent of full scale. With that information, the most accurate gauging systems, taking battery age, temperature, self-discharge, and discharge-charge cycle history into account, can usually estimate remaining battery life to within 1 percent.

How to monitor the status of an EV battery?

There are a variety of current sensing technologies that can monitor the status of an HEV or EV battery. The solution varies with the voltage and capacity of the battery. As shown in Figure 1, there are two main locations where you can measure current: top of stack (high-side sensing) and bottom of stack (low-side sensing). Figure 1.

What is a current sense resistor?

In the classical current-sensing circuit, designing for the sense resistor can bring unwelcome challenges. This saves board space and provides a four-decade sensing range. Current sense amplifiers (CSAs) are specialized amplifiers that monitor current flow by measuring a voltage drop across a sensor element.

Learn More

- How to measure the battery strength of a communication base station

- How to connect the signal line of the flow battery in the communication base station

- How long can a 200ah battery in a communication base station supply power

- How to install the aluminum box of lithium-ion battery in communication base station

- How much does the Honiara base station battery cost

- How long does it take to fully charge the base station battery

- Battery cabinet base station power current abnormality

- How to check the inverter battery of communication base station

- Base station battery host computer current

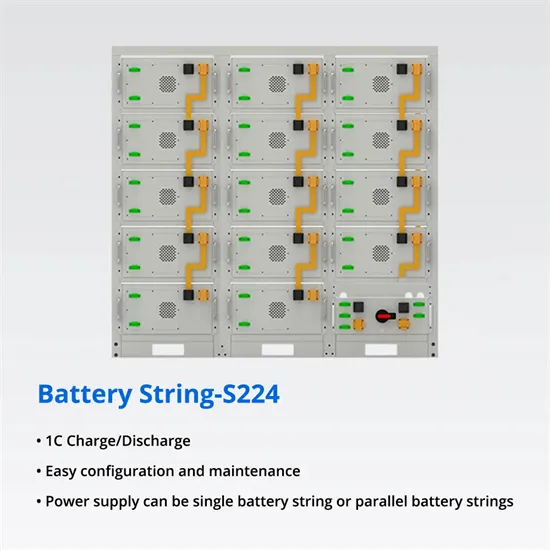

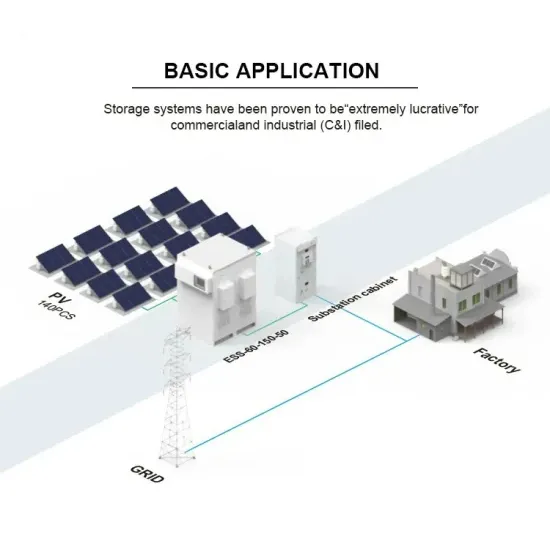

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.