Understanding the Base Station Subsystem: A

Oct 4, 2024 · In the world of mobile telecommunications, understanding the Base Station Subsystem (BSS) is paramount for grasping how our everyday communications function

Mobile Communication Network Base Station Deployment

Apr 13, 2025 · This paper discusses the site optimization technology of mobile communication network, especially in the aspects of enhancing coverage and optimizing base station layout.

What Is Base Station in Mobile Communication? – The Heart

Jan 11, 2025 · In the era of rapid technological advancements, mobile communication has become an integral part of our daily lives. With the increasing demand for high-speed data and

Battery Circuit Architecture

Aug 6, 2011 · Some designs have communication and/or interface signal lines to circuitry in the battery pack. In many cases the ESD protection on these lines does not clamp a positive

Communication Protocol Reference Guide

Sep 12, 2023 · An owner/operator of a battery system requires control of the Nuvation BMS to monitor the activity of the batteries and track battery usage and its charge/discharge activities.

Oxide filler with four setpoint setup log

Oct 6, 2020 · Connection of any signal line (load cell or communications) to the shield gives a path for noise to couple onto the measurement electronics. There is also the possibility that

(PDF) Dispatching strategy of base station backup power

Apr 1, 2023 · In this article, the schedulable capacity of the battery at each time is determined according to the dynamic communication flow, and the scheduling strategy of the standby

A Guide to BMS Communication Protocols

May 14, 2024 · Communication protocols enable real-time monitoring, control, and optimization of battery performance. These BMS communication protocols guarantee timely and effective

Understanding Base Station Subsystem: An Essential Guide

Oct 5, 2024 · The Base Station Subsystem (BSS) is a critical component of cellular networks, comprising base transceiver stations (BTSs) that connect user equipment to the network.

Traffic Prediction of Mobile Communication Base Station

Aug 14, 2024 · Simultaneously, in the age of big data information, it is possible to obtain real-time feedback of base station traffic data. By acquiring information about traffic changes in mobile

The Base Station in Wireless Communications: The Key to

Aug 7, 2024 · Base station, also known as BTS (Base Transceiver Station), is a key device in wireless communication systems such as GSM. Equipped with an electromagnetic wave

Microsoft Word

Jan 25, 2008 · These signals used the tried and tested method of line reversal but as such signals might be very frequent (up to 1 a second for international calls) there was an issue of noise

Battery configuration dependence to power line communication

Feb 15, 2024 · Power line communication (PLC) within future smart batteries facilitates the communication of high fidelity sensor data between smart cells and external systems, with

Optimizing redeployment of communication base station

Feb 6, 2025 · Most of the current research is based on the performance of the base station (BS) itself or the operation mode of the communication operator without considering the users''

Earthing Diagrams.doc

Dec 6, 2016 · Connection of any signal line (load cell or communications) to the shield gives a path for noise to couple onto the measurement electronics. There is also the possibility that

Research on Application of Power Line Communication in

Oct 13, 2024 · To build an intelligent battery management system (BMS), transmitting signals from a smart battery is an unavoidable and imminent issue. Power line communicatio.

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · Who or What is ATIS? The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and

Simulation and Classification of Mobile Communication Base Station

Dec 16, 2020 · In recent years, with the rapid deployment of fifth-generation base stations, mobile communication signals are becoming more and more complex. How to identify and classify

6 FAQs about [How to connect the signal line of the flow battery in the communication base station]

How does a BMS communicate with a central control unit?

Then, using this data, the central control unit will be able to issue commands to the BMS, for example, to limit the current output, to start the cooling process, or to isolate the battery in case of critical problems. The communication protocol is a key player in allowing the information to be exchanged.

Why do cellular base stations have backup batteries?

[...] Cellular base stations (BSs) are equipped with backup batteries to obtain the uninterruptible power supply (UPS) and maintain the power supply reliability. While maintaining the reliability, the backup batteries of 5G BSs have some spare capacity over time due to the traffic-sensitive characteristic of 5G BS electricity load.

How do you use a diode in a communication line?

To implement the first method, a diode is placed in the communication line with a parallel capacitor and high-value pull-down resist-ance on the battery side of the diode. The diode is typically a Schottky diode to reduce the impact on the communication noise margin.

What is the best design practice for a battery pack?

The best design practice is to use circuitry in the battery pack that does not have an internal substrate diode to VCC. This has a side benefit of preventing the battery-pack electronics from being able to clamp the communication line to a low VCC value resulting from a depleted battery.

How do PCB layout and connection drops affect voltage measurements?

Voltage measurements of the battery stack are also affected by PCB layout and connection drops. Some battery-pack designs may use nickel straps from the PCB connection to the battery stack. Nickel is used because it is easy to weld to the battery cells, but its resistance is five times as much as that of copper.

How do you pull up a battery pack VCC?

The electrical path to pull up the battery pack VCC passes through the host capacitance from Pack+ to Pack–, through a substrate diode in the host interface driver from VSS to the commu-nication or interface line, and through a substrate diode from this line to VCC in the battery-pack circuitry. The complete path is shown in Fig. 6.

Learn More

- How to connect the signal base station to the battery

- How to connect the cylindrical energy storage cabinet of the communication base station battery energy storage system

- How big is the flow battery in a communication base station

- How to choose the heat dissipation of the battery energy storage system of the communication base station

- How to measure the battery strength of a communication base station

- Khartoum Communication Base Station Flow Battery Tower Factory

- Communication base station flow battery equipment manufacturing company

- Communication base station flow battery detector

- How much power does the battery in a communication base station have to charge

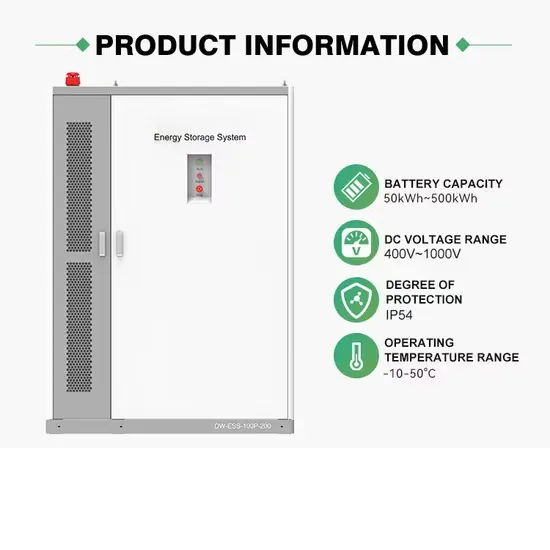

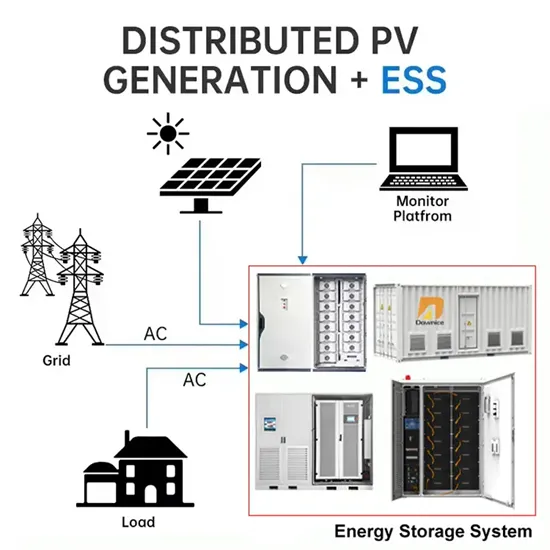

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.