Comprehensive review of energy storage systems

Jul 1, 2024 · The applications of energy storage systems have been reviewed in the last section of this paper including general applications, energy utility applications, renewable energy

Optimizing the Heat Dissipation of an Electric

Dec 23, 2014 · Lithium-ion batteries are one of the ideal energy storage systems for the electric vehicles. Generally, the battery pack has a number of battery

Energy storage system battery compartment heat

To verify the effectiveness of the cooling function of the liquid cooled heat dissipation structure designed for vehicle energy storage batteries, it was applied to battery modules to analyze

Design and research of heat dissipation system of electric

Jun 27, 2024 · This research focuses on the design of heat dissipation system for lithium-ion battery packs of electric vehicles, and adopts artificial intelligence optimization algorithm to

Heat dissipation investigation of the power lithium-ion battery

Nov 15, 2020 · In this work, the physical and mathematical models for a battery module with sixteen lithium-ion batteries are established under different arrangement modes based on the

A Review of Battery Energy Storage System Optimization:

Jan 19, 2024 · The transition away from fossil fuels due to their environmental impact has prompted the integration of renewable energy sources, particularly wind and solar, into the

Study on the influence of the thermal protection

Abstract. The thermal runaway chain reaction of batteries is an important cause of the battery energy storage system (BESS) accidents, and safety protection technology is the key

Simulation of heat dissipation model of lithium-ion

Some simulation results of air cooling and phase change show that phase change cooling can control the heat dissipation and temperature rise of power battery well. The research in this

Thermal equalization design for the battery energy storage system

Dec 15, 2024 · The adoption of fully electric ships represents a significant step forward in addressing the environmental challenges of climate change and pollution in the shipping

Latent thermal energy storage technologies and applications

Aug 1, 2020 · The article presents different methods of thermal energy storage including sensible heat storage, latent heat storage and thermochemical energy storage, focusing mainly on

Optimization of liquid cooled heat dissipation structure

Jun 27, 2024 · technology, as a widely used thermal management method, is crucial for maintaining temperature stability and uniformity during battery operation (Karimi et al., 2021).

Thermal Management Technology of 1MWh BESS Energy Storage System

Dec 27, 2024 · The 1MWh Battery Energy Storage System (BESS) is a crucial component in modern energy storage applications. As the capacity and power of BESS increase, thermal

A thermal management system for an energy storage battery

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Experimental and numerical investigation of a composite

Mar 1, 2025 · Abstract Traditional air-cooled thermal management solutions cannot meet the requirements of heat dissipation and temperature uniformity of the commercial large-capacity

The thermal analysis of the heat dissipation system of the

Oct 1, 2023 · The charging speed of the charging piles was shorted rapidly, which was a challenge for the heat dissipation system of the charging pile. In order to reduce the operation

Understanding Battery Energy Storage Systems (BESS)

Apr 23, 2024 · Conclusion In conclusion, Battery Energy Storage Systems (BESS) represent a pivotal technology in the transition towards a more sustainable and resilient energy future.

A thermal perspective on battery safety

May 28, 2025 · Excessive heat generation in batteries can result in thermal runaway and fires incidents. This Perspective examines thermal runaway characteristics and propagation and

Numerical study on heat dissipation performance of a

Aug 30, 2023 · The simulation model is validated by the experimental data of a single adiabatic bare battery in the literature, and the current battery thermal management system based on

Battery Energy Storage Systems Cooling for a

Feb 26, 2024 · Why Thermal Management makes Battery Energy Storage more efficient Energy storage plays an important role in the transition towards a carbon-neutral society. Balancing

Thermal equalization design for the battery energy storage system

Dec 15, 2024 · The Battery Energy Storage System (BESS), as the primary power source for electric ships, must maintain its temperature within an appropriate range to ensure safe

Research on the heat dissipation performances of lithium-ion battery

Nov 8, 2024 · Lithium-ion power batteries have become integral to the advancement of new energy vehicles. However, their performance is notably compromised by excessive

Review on the heat dissipation performance of battery pack

Jan 1, 2014 · This paper reviews the heat dissipation performance of battery pack with different structures (including: longitudinal battery pack, horizontal battery pack, and changing the

Research progress on the optimization of thermal

Accordingly, LIBs must simultaneously achieve high energy efficiency, extended cycle life, and rigorous safety standards to optimize NEV system performance. However, LIBs still face

Transient heat dissipation performance investigation on the battery

Mar 1, 2025 · The traditional air-based heat dissipation technology is gradually difficult to meet the heat dissipation needs of high heat generation of power battery [22]. The PCM-based cooling

Numerical simulation and optimal design of heat dissipation

Oct 13, 2024 · Container energy storage is one of the key parts of the new power system. In this paper, multiple high rate discharge lithium-ion batteries are applied to the r

A review of battery energy storage systems and advanced battery

May 1, 2024 · To maintain the battery at its ideal working temperature, a battery thermal management system (BTMS) must carry out essential functions like heat dissipation through

Heat dissipation analysis and optimization of lithium-ion batteries

Jun 15, 2022 · The design of thermal management system affects the safety, cycle life, and operating cost of lithium-ion battery. This paper discusses the structure

Adaptive battery thermal management systems in unsteady

Oct 1, 2024 · Simultaneously, in the practical application of battery energy storage system (BESS), which contains a large number of large-scale battery cells, BTMSs with long operating

A review on effect of heat generation and various thermal management

Dec 1, 2020 · Currently, lithium-ion batteries are receiving the attention of industries like automobiles, electronics, aerospace and so on due to its high energy density, power density

Numerical Simulation and Optimal Design of Air Cooling Heat Dissipation

Jan 1, 2022 · Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence

Designing effective thermal management systems for

Apr 10, 2025 · By capturing real-world behavior virtually, engineers can evaluate the effects that different operating conditions and thermal management strategies have on various design

Integrating Electrochemical and Thermal Models for

May 3, 2025 · Abstract Lithium-ion batteries (LIBs) are widely used in electrochemical battery energy storage systems (BESS) because of their high energy density, lack of memory effects,

Energy management strategy of Battery Energy Storage Station

Sep 1, 2023 · In recent years, electrochemical energy storage has developed quickly and its scale has grown rapidly [3], [4]. Battery energy storage is widely used in power generation,

Review on heat dissipation methods of lithium-ion power battery

Finally, to address the issues that exist in the current heat dissipation methods of power batteries, the battery thermal management system (BTMS) is proposed by combining it with the car

6 FAQs about [How to choose the heat dissipation of the battery energy storage system of the communication base station]

Does guide plate influence air cooling heat dissipation of lithium-ion batteries?

Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling.

How to improve the heat dissipation of a battery?

The staggered arrangement is more conducive to improving the heat dissipation of a battery, as it avoids the shielding of the airflow by the battery. Controlling the uniformity of the heat dissipation mode is also crucial to prevent large differences.

Can phase change cooling control the temperature rise of power battery?

According to some simulation results, phase change cooling can effectively control the heat dissipation and temperature rise of a power battery. The research in this paper offers valuable theoretical guidance for the temperature rise, heat transfer, and thermal management of automotive power batteries.

What is the temperature distribution of a battery?

The temperature distribution of a battery is represented by a cloud map. The temperature limits of the battery are 47.42 °C and 41.92 °C respectively, and are interpolation-controlled at 5.5 °C. The heat inside the battery pack is difficult to emit to the outside world and is affected by the thermal radiation from the surrounding areas, leading to heat concentration.

How does battery arrangement affect the temperature of a battery pack?

The temperature of a lithium-ion battery pack is affected by the heat concentration, which is influenced by the thermal radiation from the surrounding areas. The battery arrangement, such as staggered contrast regular arrangement, has a linkage effect on the temperature of the battery. Recommended arrangement: interleaved.

What is a Battery Thermal Management System?

A Battery Thermal Management System, as the name suggests, is a system designed to control the battery to ensure it operates in the appropriate environment. In practical applications, considering cooling cost and efficiency, air cooling, liquid cooling, and phase change cooling have become the mainstream methods.

Learn More

- How to start a communication base station battery energy storage system

- How to connect the cylindrical energy storage cabinet of the communication base station battery energy storage system

- How many communication base station battery energy storage systems are there in the Marshall Islands

- Communication base station battery energy storage system 5GRUBU

- Communication base station battery energy storage system secondary load

- 2MWH Communication Base Station Battery Energy Storage System Power Generation Company

- The working power generation of the communication base station battery energy storage system includes

- Battery energy storage system main equipment main control board for communication base station

- How to build a flywheel energy storage project for a communication base station

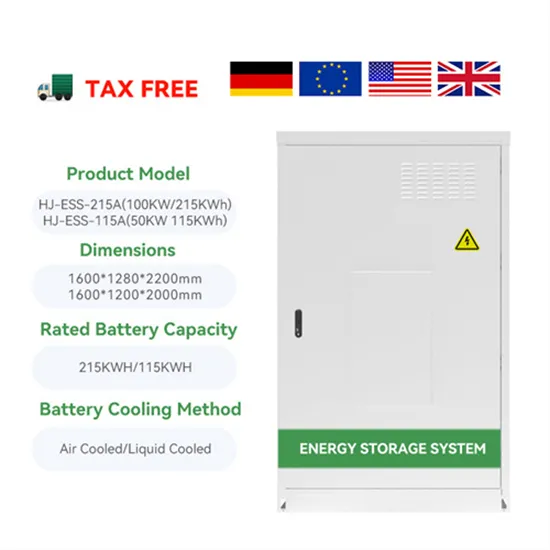

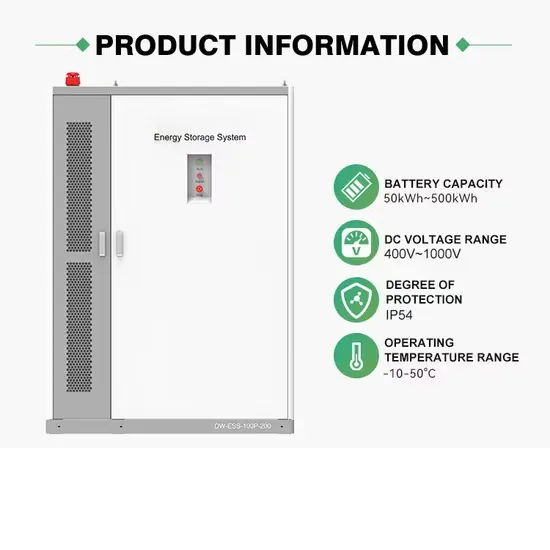

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.