The Ultimate Guide to Building a DIY LifePO4 Battery Box

Jan 22, 2024 · Learn how to build your own DIY LifePO4 battery box with this comprehensive guide. From choosing the right battery box to implementing safety measures, this article

Life Cycle Assessment of Lithium-ion Batteries: A Critical

May 1, 2022 · Evolving technological advances are predictable to promote environmentally sustainable development. Regardless the development of novel technologies including Li-ion

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Connect the Cells: Use a high-voltage laser welding machine (2KW or 6KW) to weld cells in series or parallel configurations. Attach Nickel Strips: Weld nickel or aluminum strips to

How to build a 12v 200ah lithium ion battery

Nov 22, 2019 · For a comprehensive step-by-step guide, including tools needed, cell types (like LiFePO4, which is popular for its safety and longevity), and assembly tips, I recommend

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · This technical guide examines the internal structure of lithium ion batteries and provides detailed procedures for constructing battery packs from individual components. The

How to build a 12v 200ah lithium ion battery

Nov 22, 2019 · I just picked up cells for 24v 200 ah lifepo4 battery array. Going to make my own power station with 3kw inverter all mounted i aluminum case I paid 125 for them. The original

DOE ESHB Chapter 3: Lithium-Ion Batteries

Mar 17, 2021 · Abstract Lithium-ion batteries are the dominant electrochemical grid energy storage technology because of their extensive development history in consumer products and

How to Build a Lithium Ion Battery Box: Essential Tips and

Feb 21, 2025 · Building a lithium-ion battery box requires careful planning and execution to ensure safety and efficiency. By understanding the essential components, choosing the right

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · The few telecom battery fires have been related to installation mistakes Lithium-Ion Electrolyte can be highly flammable Electronic controllers – potentially prone to failure are

Lithium Battery Installation Guidance Document

Nov 30, 2023 · Recreational Vehicle installations are almost exclusively lithium-iron-phosphate batteries, installed with robust battery management systems. These battery systems are a

Build Your Own DIY Battery Box for LiFePO4 Batteries

Dec 25, 2023 · Learn how to build a DIY battery box for LiFePO4 batteries, ensuring optimal performance and safety. Choose the right enclosure, design the layout, implement proper

An overview and prospective on Al and Al-ion battery technologies

Jan 1, 2021 · Several electrochemical storage technologies based on aluminum have been proposed so far. This review classifies the types of reported Al-batteries into two main groups:

Assemble Lithium Battery: Step-by-Step Guide, Tools,

Learn how to assemble a lithium battery by yourself with our step-by-step guide. Discover the essential tools, materials, and safety precautions needed for successful assembly. Our

6 FAQs about [How to install the aluminum box of lithium-ion battery in communication base station]

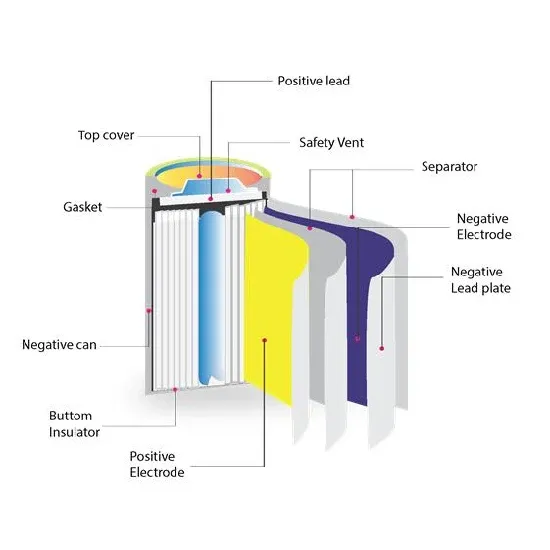

What is lithium ion battery assembly?

Lithium-Ion Battery Assembly: Involves stacking layers of anodes, cathodes, and separators. Assembly techniques include winding for cylindrical cells and stacking for prismatic cells. Requires careful handling of liquid electrolytes during assembly. Lithium Polymer Battery Assembly:

What is a battery box?

Battery boxes serve many purposes. Like any box, it is a means of storage. It securely houses the battery cells, a battery management system (BMS), and electrical connections that make up the battery. Along with keeping components in, the box also keeps hazards out by protecting the cells not only from impacts but also electrical shorts.

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

How do you test a lithium battery pack?

Voltage and Current Testing: Use a multimeter to ensure the pack operates within safe parameters. Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How do you insulate a battery pack?

Attach Nickel Strips: Weld nickel or aluminum strips to connect the cells securely. Integrate the BMS: Weld the BMS to the battery pack, ensuring all connections are precise and insulated. 4. Insulate and Secure the Pack Wrap the Pack: Use insulating materials like fish paper or heat shrink tubing to protect the cells and connections.

Learn More

- How to use the base station battery as a communication power supply

- Communication base station lithium-ion battery construction qualification enterprise

- How is the battery of Warsaw communication base station

- How to connect the power supply battery of the communication base station

- How big is the flow battery in a communication base station

- Rooftop communication base station lithium-ion battery project

- How to connect the cylindrical energy storage cabinet of the communication base station battery energy storage system

- How to install a new energy communication base station

- How far is the distance of communication base station battery power generation

Industrial & Commercial Energy Storage Market Growth

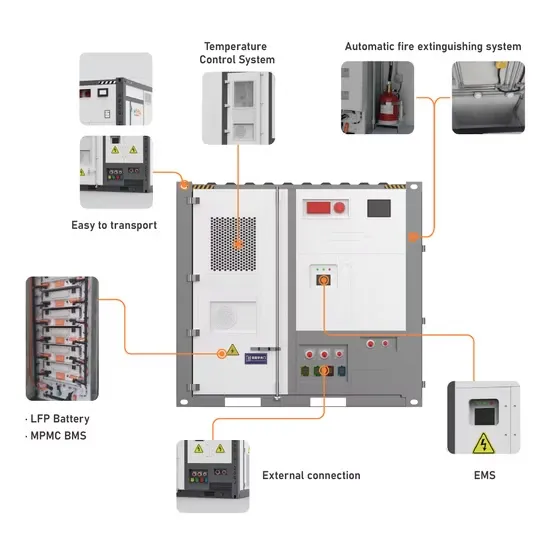

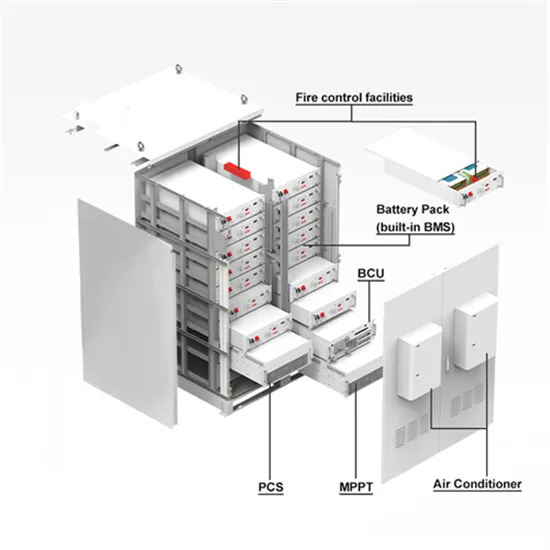

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.