Power electronics inverters Market Size, Production, Sales,

Jul 16, 2025 · Power electronics inverters market analysis, production, capacity, average price, market share, top market trends, import vs export: country-wise analysis

Inverter production process: from raw materials to finished

Nov 16, 2024 · take a deep look at the production process of inverters, from the procurement of raw materials to the final product, revealing the manufacturing secrets of this high-tech product.

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · In large-scale applications such as PV power plants, "high-power" in medium voltage (MV) inverters is characterized by the use of multilevel inverters to enhance efficiency

The top ten inverter manufacturers in China

The following are the top ten domestic inverter manufacturers with the greatest development potential in China''s inverter industry that have been sorted out: Shenzhen Yunhai Power: A

Infineon high voltage Inverter Application Presentation

May 25, 2025 · For EV traction inverter, more efficiency and right performance are key. While IGBT is ideal for cost-optimized drive-train, SiC demonstrates higher efficiency under WLTP

High-power-density Inverter Technology for Hybrid and

Dec 18, 2024 · High-power-density Inverter Technology for Hybrid and Electric Vehicle Applications Takashi Kimura Ryuichi Saitou Kenji Kubo Kinya Nakatsu Hideaki Ishikawa

How Solar Inverters Efficiently Manage High-Temperature

Mar 6, 2025 · High temperatures can reduce solar inverter efficiency, limit power output, and shorten lifespan. Learn how heat impacts inverter performance and discover expert tips for

High-power-density Inverter Technology for Hybrid and

Mar 9, 2024 · The components used in the high-voltage and heavy-current power sections of the inverter required a high level of insulation and the ability to withstand high voltages.

high-power inverter based hybrid switch SiC+IGBT

Mar 19, 2024 · Hybrid switch configuration considfred is 1:4 ratio (1 SiC + 3 IGBTs) Efficiency gain of full SiC Inverter and hybrid switch inverters vs IGBT inverter is from low load to medium

Recent developments of high power converters for industry and traction

Nov 30, 2000 · The characteristics of IGCTs and high voltage IGBTs are described in detail. Both the design and loss simulations of a two level 1.14 MVA voltage source inverter and a 6 MVA

BorgWarner Sites Celebrated Production of 1,000,000th Inverter

Nov 15, 2022 · Read and download our latest press releases.Two BorgWarner production facilities achieved major milestones: Suzhou facility producing its 1,000,000 th inverter and the

6 FAQs about [Production of high power inverter]

What is a high-power MV inverter?

In large-scale applications such as PV power plants, "high-power" in medium voltage (MV) inverters is characterized by the use of multilevel inverters to enhance efficiency and scalability. These high-power MV systems generally function within a power range of 0.4 MW–40 MW, and in certain applications, can reach up to 100 MW.

What are the applications of control systems in high-power inverters?

One of the application of control systems in high-power inverters is to increase the speed and accuracy in achieving MPPT. Control algorithms continuously examine the input of the inverter and adjust its operational parameters to extract the maximum available power . Another essential factor is computational complexity.

How to achieve high output power levels in ChB-based inverters?

In order to attain elevated output power levels, obviate the necessity for low-frequency transformers, generate multilevel output voltage, and implement distributed MPPT, a novel three-phase topology has been introduced in Ref. tailored for CHB-based inverters.

What is a high-power string inverter?

High-power string inverters, rather than simply making centralized inverters smaller or string inverters larger, take into account the low cost of centralized inverters and the flexibility of small-power string inverters. It is a market-oriented product that has evolved in response to industry changes.

What are PWM techniques in LS-PV-PP high-power inverters?

In reviewing various PWM techniques in LS-PV-PP high-power inverters, we find that these techniques focus on optimizing the conversion of DC power from solar panels to AC power to inject an appropriate output power into the main grid.

Are high-power ChB inverters able to control output power?

One of the inherent issues in high-power CHB inverters is the imbalance in the output power, leading to instability and reduced current in grid-connected systems. Therefore, an adaptive control technique has been proposed to regulate the output power in these converters.

Learn More

- 3000w high power inverter

- Electricity storage high power inverter

- Micronesia le series high power inverter manufacturer

- Inverter power frequency high frequency

- High power inverter charging

- Power frequency solar off-grid inverter high power

- Energy storage inverter high power IGBT model

- High power inverter quotation

- What is the maximum power of a 12v high power inverter

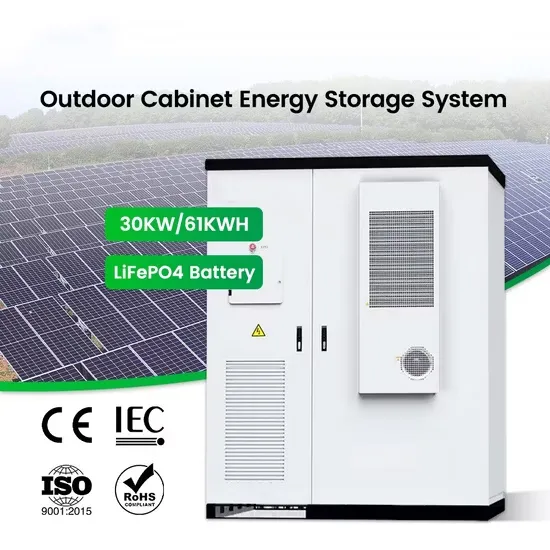

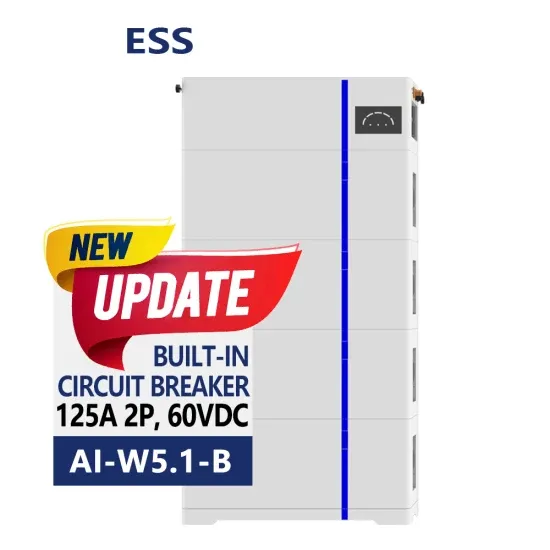

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.