High-Density SiC and Si Inverter Stack Reference

Mar 12, 2017 · The stack reference models were assembled under the "Integrated Architecture" approach in close collaboration with partners Infineon,

Energy storage system: Current studies on batteries and power

Feb 1, 2018 · The power conversion system determines the operational condition of the entire energy storage system. The new generation wide bandgap semiconductor for power electronic

International Journal of Soft Computing and Engineering

Feb 23, 2022 · Abstract: The paper represents the design of a 100 kW three-phase network inverter for a hybrid energy storage system based on batteries and supercapacitors. The

High Power Density IGBT Loss Calculation Model

Feb 19, 2025 · This paper presents the establishment of an accurate loss model for high-power-density IGBT modules used in electric vehicles, leveraging the

The Next Generation of High Power IGBT Modules

Mar 13, 2025 · A new high power IGBT module (LV100 for industrial) is under devel-opment, which has been optimized for the requirements of high power applications in the field of

High-Performance Inverters Powered by Latest IGBT Modules

Aug 8, 2024 · The modules are based on the latest Field Stop 7 (FS7) IGBT technology which delivers the highest levels of performance in high-power applications including solar inverters,

New IGBT, SiC Power Modules Meet High-Voltage Needs

May 2, 2025 · High-power applications, such as industrial and automotive, require power module solutions that offer performance under intense temperatures and high voltages. Infineon and

Inverter reliability-constrained Volt/Var optimization control

Dec 15, 2023 · In response to the issue of the impact of PV-storage power participating in distribution network volt/var regulation on the IGBT reliability and lifespan of PV-storage

Tesla''s Innovative Power Electronics: The Silicon Carbide Inverter

Feb 17, 2021 · Why is Tesla ''s inverter innovative? Well, with the release of the Model 3 in 2018, Tesla became the first company to add SiC metal-oxide-semiconductor field-effect transistors

Power Configuration-Based Life Prediction Study of IGBTs in Energy

Apr 2, 2024 · An energy storage converter system consists of an energy storage medium and bi-directional converter, and IGBT is the core device of an energy storage bi-directional

DOE ESHB Chapter 13 Power Conversion Systems

Sep 3, 2021 · Key Terms Energy storage, insulated gate bipolar transistor (IGBT), metal oxide semiconductor field effect transistor (MOSFET), power conversation systems (PCS), power

Inverter reliability-constrained Volt/Var optimization control

Dec 15, 2023 · The maximum output power of PV-storage power supply under IGBT junction temperature constraint is solved by dichotomy, so the transformation from IGBT junction

Original New TBK7-06-30 IGBT Thyristor Module Scr Gate

Original New TBK7-06-30 IGBT Thyristor Module Scr Gate Driver Control Diode for Energy Storage System Invert Igbt Power We produce: Fast turn-off thyristor, Phase control thyristor,

High voltage energy storage igbt

hes and four high-voltage types. Energy storage can be provided by charging a battery from the inverter AC output using a matches the on-state losses of an IGBT at high currents, but that

high-power inverter based hybrid switch SiC+IGBT

Mar 19, 2024 · high-power inverter based hybrid switch SiC+IGBT technology Gianni Vitale, Application Director Halbig, Senior Marketing Manager STMicroelectronics

The development of IGBT double-sided cooling

Dec 19, 2023 · The full name of IGBT is insulated gate bipolar transistor. It is characterized by voltage control, high voltage withstanding, small saturation

EV Traction Inverter Design Guide Using Isolated IGBT

Apr 1, 2023 · This document describes how to design a HEV/EV traction inverter drive system using the advantages of TI''s isolated gate drivers diagnostic and protection features.

Three Phase Pure Sine Wave on/off Grid Energy Storage IGBT

Jul 21, 2025 · The BNSX series bidirectional energy storage inverter serves as an electrical interface between the power grid and energy storage devices, with the main function and role

High-Power String Inverters and 800Vac Solutions for

Apr 5, 2022 · • High power String Inverters are now rated to 275kW, or higher • Increased power density, small physical size • Standard H-bridge to 3 and 5-Level topologies • Transformerless

Energy Storage IGBT: The Unsung Hero Behind Efficient Power

Mar 28, 2022 · Why Your Energy Storage System Needs a Better "Traffic Cop" Ever wondered how solar farms store sunshine for rainy days or how wind turbines keep the lights on when

Energy storage inverter high power igbt model

.V LV100 High Power IGBT Modules for Wind Energy Storage; Generation; Microgrid; Power Supplies; Reliability & ality, has propelled the development of IGBT. In the realm of photovolta

6 FAQs about [Energy storage inverter high power IGBT model]

What is a high power IGBT module (LV100 for industrial)?

A new high power IGBT module (LV100 for industrial) is under devel-opment, which has been optimized for the requirements of high power applications in the field of renewable energy converters, and industrial drives. The outline of the module housing is same as HVIGBT LV100 and in line with the new market defacto standard.

Do IGBT modules experience thermal cycling in high power industrial drive applications?

IGBT modules in high power industrial drive applications experience thermal cycling in case of fluctuating (or non-continuous) loads. Wind power converters are usually liquid-cooled with the cooler hav-ing a thermal time constant of a couple of seconds.

What is the difference between SIC vs IGBT inverter?

Hybrid switch configuration considfred is 1:4 ratio (1 SiC + 3 IGBTs) Efficiency gain of full SiC Inverter and hybrid switch inverters vs IGBT inverter is from low load to medium load, generating advantages in power systems that operate most of the time below 40% load Hybrid switch inverter shows similar efficiency curve compared to SiC.

Should an inverter designer change from IGBT to SiC-MOSFET?

Therefore, if an inverter designer considers changing to SiC devices in future, the LV100 package is the right choice since the layout concept is ready for SiC . As result, a potential future change from Si-IGBT to SiC-MOSFET devices is feasible with less changes and redesign efforts.

What is a high power switch in an inverter?

The high-power switches are the most critical component in the inverter as they control the flow of current to the motor to generate motion. As such, the switches' are monitored and protected by sensing their temperature, voltage and current throughout their operation.

Why are multiple IGBT chips connected in a Paral-lel configuration?

In high power IGBT modules, multiple chips are connected in a paral-lel configuration because IGBT chips sizes are limited and usually the rating maximum current is in a range of ~200A for IGBT chips with blocking voltages of 1200V or 1700V.

Learn More

- Wind power communication base station inverter grid-connected energy storage cabinet

- The role of the inverter device in energy storage power stations

- What are the high voltage energy storage power stations

- New energy storage power station operation model

- Base station lithium battery energy storage 15kw inverter power supply

- Energy storage equipment and inverter power

- Solar high power gas energy storage cabinet

- Libya high power energy storage equipment

- Operational model of energy storage power station

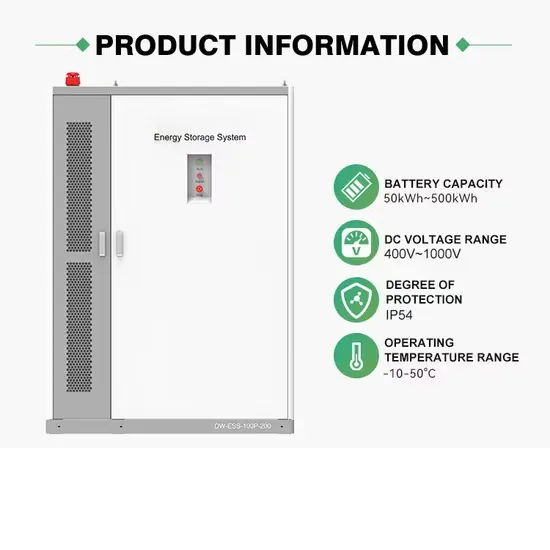

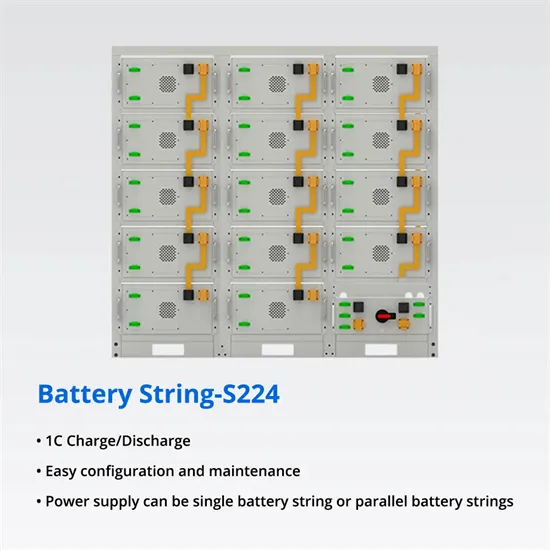

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.