Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Electromagnetic catapult inertial energy storage flywheel

Are flywheel energy storage systems a good alternative to electrochemical batteries? Flywheel energy storage systems are considered to be an attractive alternative to electrochemical

Flywheel Energy Storage System | PDF | Electric

Mar 16, 2024 · Flywheel Energy Storage System Seminar Links f Introduction A flywheel, in essence is a mechanical battery - simply a mass rotating about an

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · Energy storage systems (ESS) play an essential role in providing continu-ous and high-quality power. ESSs store intermittent renewable energy to create reliable micro-grids

A COMPREHENSIVE REVIEW ON FLYWHEEL ENERGY STORAGE SYSTEMS

What is a flywheel energy storage system? First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber

Flywheel energy storage industry layout analysis and design plan

Design and prototyping of a new flywheel energy storage system 1 Introduction. Among all options for high energy store/restore purpose, flywheel energy storage system (FESS) has been

An Introduction to Energy Storage

May 27, 2020 · The goal of the DOE Energy Storage Program is to develop advanced energy storage technologies and systems in collaboration with industry, academia, and government

PROJECT PROFILE FLYWHEEL ENERGY STORAGE

Are flywheel energy storage systems environmentally friendly? Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to

Flywheel energy storage principle video tutorial

ment describes a flywheel energy storage system. It includes an introduction, block diagram, theory of operation, design, components, circuit diagr m, advantages and disadvantages, and

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheel Energy Storage (FES) system is an electromechanical storage system in which energy is stored in the kinetic energy of a rotating mass. Flywheel systems are

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Design and Simulation of a Robotic System Integrated With Flywheel

Jun 26, 2025 · To address power interruptions, a flywheel energy storage system (FESS) was designed to ensure the continuation of operations.

Flywheel energy storage principle video tutorial

This document describes a flywheel energy storage system. It includes an introduction, block diagram, theory of operation, design, components, circuit diagram, advantages and

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Flywheel energy storage device electromagnetic ejection

Among the different mechanical energy storage systems,the flywheel energy storage system (FESS) is considered suitable for commercial applications. An FESS,shown in Figure 1,is a

A review of energy storage technologies for wind power

May 1, 2012 · The main objectives of the article are the introduction of the operating principles, as well as the presentation of the main characteristics of energy storage technologies suitable for

EK flywheel energy storage introduction

This chapter provides a general introduction to the topic of flywheel energy storage systems with a focus on vehicular applications. It touches upon historical aspects, covering not only

Flywheel Energy Storage: A Comprehensive Guide

Flywheel energy storage (FES) is a kinetic energy storage technology that utilizes a rotating flywheel to store energy. The flywheel is connected to an electrical machine that acts as a

Introduction | SpringerLink

May 4, 2023 · This chapter provides a general introduction to the topic of flywheel energy storage systems with a focus on vehicular applications. It touches upon historical aspects, covering not

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

6 FAQs about [EK flywheel energy storage introduction]

What is a flywheel energy storage system?

Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies. A FESS consists of several key components: (1) A rotor/flywheel for storing the kinetic energy. (2) A bearing system to support the ro-tor/flywheel.

Could flywheels be the future of energy storage?

Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research [152,153] studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

Can flywheel energy storage system improve frequency regulation?

Inertia emulation by flywheel energy storage system for improved frequency regulation. In 2018 IEEE 4th southern power electronics conference (SPEC) (pp. 1–8). IEEE. A review of control strategies for flywheel energy storage system and a case study with matrix converter Zhou, Y., Li, Y., Lv, Q., Lv, D., Yang, Y., & Zheng, J. (2020).

Do flywheel energy storage systems support fast charging stations?

Fast charging stations supported by flywheel energy storage systems. In 2020 IEEE 5th international conference on computing communication and automation (ICCCA) (pp. 109–113).

Learn More

- EK flywheel energy storage equipment

- Introduction to Belize EK s energy storage system

- Introduction to EK Energy Storage Batteries in South America

- Flywheel energy storage hydraulic system

- Flywheel Energy Storage Energy Management

- Flywheel energy storage device solution

- What are the flywheel energy storage installation projects for communication base stations

- Ashgabat Motor Flywheel Energy Storage

- Advanced flywheel energy storage system

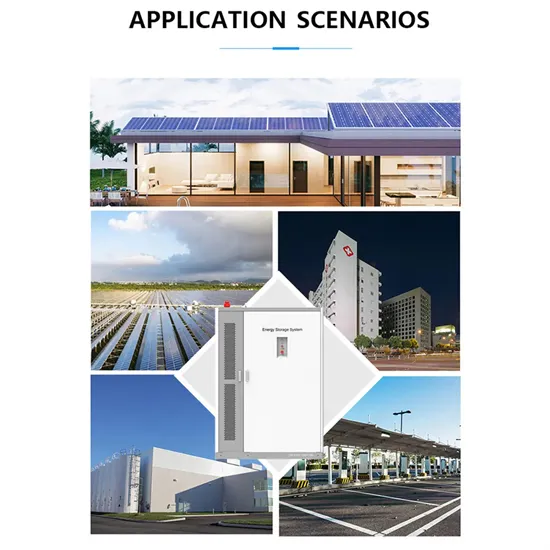

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.