Role of Flywheel Batteries in Energy Storage System

Jun 4, 2022 · A flywheel stores mechanical energy that is converted to electrical energy by an electrical machine with a reciprocal power converter in flywheel-based energy storage systems.

Battery and Flywheel hybridization of a reversible Pumped-Storage

Nov 1, 2023 · Other energy storage devices cannot compete with PSHP in terms of energy and power availability. The aim of this research is to assess the benefits derived from the

A Numerical and Experimental Study of Flywheel Energy Storage

Several avenues for rectifying the low energy storage density of hydraulic systems have attracted research interest.One such avenue is the application of kinetic energy storage, or flywheels, to

Advancing renewable energy: Strategic modeling and

Nov 1, 2024 · This study introduces a hybrid energy storage system that combines advanced flywheel technology with hydrogen fuel cells and electrolyzers to address the variability

Strategies to improve the energy efficiency of hydraulic

Request PDF | On Mar 1, 2023, Xiaopeng Yan and others published Strategies to improve the energy efficiency of hydraulic power unit with flywheel energy storage system | Find, read and

Flywheel energy storage systems for power systems

Jun 29, 2017 · The ever increasing penetration of renewable and distributed electricity generation in power systems involves to manage their increased complexity, as well as to face an

A Study of Hydraulic Hybrid Vehicle Topologies with Flywheel Energy Storage

Nov 7, 2017 · The principles revealed by this study allow for the potential of significantly increased energy storage density in hydraulic systems while retaining the power density and ruggedness

A Critical Analysis of Flywheel Energy Storage Systems''

Dec 21, 2024 · A Critical Analysis of Flywheel Energy Storage Systems'' Technologies, Applications, and Prospects Published in: 2024 IEEE International Conference on Power

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully

A Study of Hydraulic Hybrid Vehicle Topologies with Flywheel Energy Storage

Nov 7, 2017 · This analysis reveals that energy loss behavior in the hydraulic pump/motors is dominating, that 3 hydraulic pump/motor topologies are more efficient due to their effect on

Various Concepts on Variable Inertia Flywheel in Rotating System

Jun 8, 2023 · Variable inertia flywheel is an innovative approach for storing energy in a rotating system. It may replace the constant inertia flywheel effectively from the conventional rotating

Design optimization, construction, and testing of a hydraulic flywheel

Dec 1, 2021 · The hydraulic flywheel accumulator is a dual domain energy storage system that leverages complimentary characteristics of each domain. The system involves rotating a

A series hybrid "real inertia" energy storage system

Dec 1, 2018 · The proposed flywheel based energy storage concept Series Hybrid Kinetic Energy Storage System (SHyKESS). Note that, in the present work, the DDU may be through of as a

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Strategies to improve the energy efficiency of hydraulic

To cope with this problem, this paper proposes an energy-recovery method based on a flywheel energy storage system (FESS) to reduce the installed power and improve the energy

Flywheel-Accumulator for Compact Hydraulic Energy

Apr 29, 2010 · A solution to bridge this gap is to improve the energy storage per unit mass of a hydraulic accumulator by storing energy as potential and rotating kinetic energy in a flywheel

Design optimization of a hydraulic flywheel accumulator for a hydraulic

Nov 3, 2015 · The hydraulic flywheel accumulator is a novel energy storage device that has the potential to overcome major drawbacks of conventional energy storage methods for mobile

A Numerical and Experimental Study of Flywheel Energy Storage

It then explores various mobile hydraulic flywheel topologies and their control strategies when applied to a hydraulic hybrid truck. To understand and model the HFA this study presents an

6 FAQs about [Flywheel energy storage hydraulic system]

What is a flywheel energy storage system?

Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies. A FESS consists of several key components: (1) A rotor/flywheel for storing the kinetic energy. (2) A bearing system to support the ro-tor/flywheel.

What is flywheel/kinetic energy storage system (fess)?

and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the recent

How do fly wheels store energy?

Fly wheels store energy in mechanical rotational energy to be then converted into the required power form when required. Energy storage is a vital component of any power system, as the stored energy can be used to offset inconsistencies in the power delivery system.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research [152,153] studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

What is a hydraulic excavator boom subsystem with a flywheel-based energy recovery system?

Schematic of a hydraulic excavator boom subsystem with the flywheel-based energy recovery system. In Fig. 10, a flywheel is employed as the energy storage device in the assistant power source. Considering the existing boom cylinder, a hydraulic machine is used as an energy converter.

Learn More

- Supercapacitor flywheel energy storage

- Flywheel energy storage disc material

- What is flywheel battery energy storage

- Advantages and disadvantages of flywheel energy storage UPS

- Flywheel energy storage magnification

- Abu Dhabi atz flywheel energy storage

- Production of energy storage flywheel

- FPGA flywheel energy storage

- Morocco 50MW flywheel energy storage

Industrial & Commercial Energy Storage Market Growth

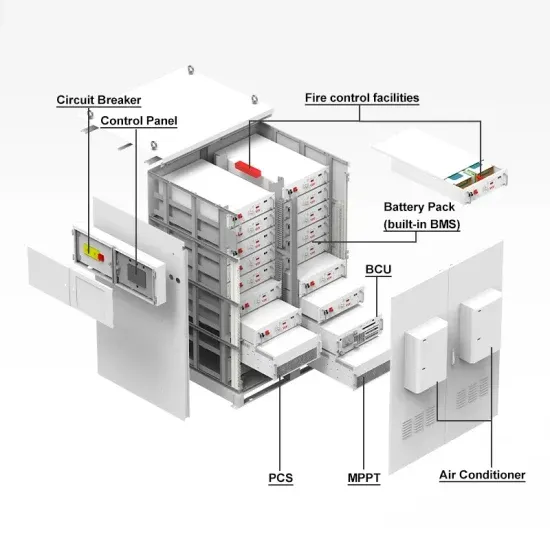

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.