Best 5 Wholesale Suppliers for energy storage battery in Bhutan

Aug 28, 2024 · The process of finding top battery manufacturers who are equally inclined towards environmental stewardship is the first step for deriving sustainable energy solutions in Bhutan.

Bhutan lithium energy storage power supply manufacturer

Supreme Lithium Energy. Supreme Lithium Energy is a pioneer in the Indian Lithium-ion battery industry. With state-of-the-art manufacturing and Design facilities, We are a supplier of high

Battery Pack Production Process

Based on the guide Production Process of Lithium-Ion Battery Cells, this document presents the process chain for the production of battery modules and battery packs. The individual cells are

Bhutan energy storage battery manufacturer

Dragonfly Energy has advanced the outlook of North American lithium battery manufacturing and shaped the future of clean, safe, reliable energy storage. Our domestically designed and

Lithium Battery Refurbishment Bhutan

The Ultimate Guide to EV Battery Maintenance and Repair When a lithium-ion battery arrives at the repair centre, it goes through a process consisting of testing and diagnosis, repair, and

Leading Battery Pack Manufacturers in China: A

May 4, 2025 · Fun Fact: Lishen has been a pioneer in the battery industry for over two decades, consistently pushing the boundaries of what''s possible with

Bhutan lithium energy storage power supply direct sales

China Portable Power Stations Manufacturer, Home Energy Storage System, Lithium Battery Pack Supplier China Portable Power Stations Supplier, Home Energy Storage System, Lithium

Bhutan Lithium Ion Cell and Battery Pack Market (2024

Market Forecast By Power Capacity (5-25 Wh, 48-95 Wh, 18-28 KWh, 100-250 KWh, More than 300 KWh), By Pack Type (Series Battery Pack, Parallel Battery Pack), By Battery Shape

Battery production factory in Bhutan

Top 10 lithium battery production equipment companies in In 2021, the company''''s lithium battery production equipment will achieve revenue of 938 million RMB, accounting for 80.93%

Battery Pack Production Process

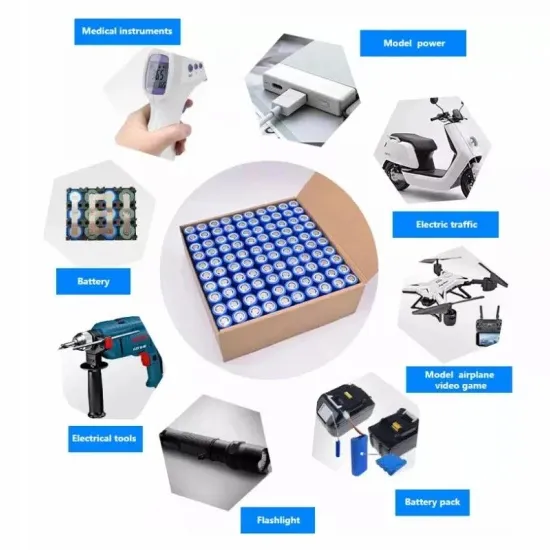

At the heart of the battery industry lies an essential lithium ion battery assembly process called battery pack production. In this article, we will explore the world of battery packs, including

BATTERY PRODUCTION FACTORY IN BHUTAN

What are the three parts of battery pack manufacturing process? Battery Module: Manufacturing, Assembly and Test Process Flow. In the Previous article, we saw the first three parts of the

Top Lithium-Ion Battery Manufacturers Suppliers in Bhutan

Jul 14, 2025 · Wholesale Lithium-Ion Battery for PV Systems? Simply put, a lithium-ion battery (commonly referred to as a Li-ion battery or LIB) is a type of rechargeable battery that is

Battery Pack Production Process

called battery pack production. In this article, we will explore the world of battery packs, including how engineers evaluate and design custom solutions, the step-by-step manufacturing process,

Bhutan Battery Pack Modules Market (2025-2031) | Analysis

Market Forecast By Battery Type (Alkaline Battery, Lithium Ceramic Battery, Nickel Metal Hydride Battery, Lithium-ion Battery, Nickel Cadmium Battery, Lead Acid Battery, Others), By

Learn More

- Albania lithium battery PACK factory

- Brazil lithium battery pack factory

- Export lithium iron phosphate battery pack factory

- Long battery life and high power lithium battery pack

- Czech household energy storage lithium battery pack

- Class 9 lithium battery pack identification

- ASEAN lithium battery pack manufacturers

- Lithium battery pack medium and high voltage box

- Ljubljana single lithium battery pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.