Bidirectional DC-AC Solution in Solar Application System

Apr 1, 2023 · ABSTRACT This application note presents a detailed solution for implementing a 3-phase solar inverter application system based on the TMS320F28035 microcontrollers

How to Use DC to AC Inverter: Examples, Pinouts, and Specs

Learn how to use the DC to AC Inverter with detailed documentation, including pinouts, usage guides, and example projects. Perfect for students, hobbyists, and developers integrating the

DC to AC Converters Inverters

Nov 21, 2017 · Converts DC to AC power by switching the DC input voltage (or current) in a pre-determined sequence so as to generate AC voltage (or current) output. Output of the inverter

How do inverters convert DC electricity to AC?

Mar 6, 2025 · Appliances that need DC but have to take power from AC outlets need an extra piece of equipment called a rectifier, typically built from electronic components called diodes,

DC to AC Power Conversion Explained: Your Guide to Inverters

Jul 28, 2025 · Inverters change DC power from solar panels into AC power. This makes it usable for home appliances like TVs and fridges. Picking an inverter with over 95% efficiency saves

Converting DC to AC: Basic Principles of Inverters

May 28, 2024 · This article investigates the basic principles of inverters, different types of DC-to-AC conversion, and common applications for generating AC

DC to AC Conversion (INVERTER)

May 23, 2013 · DC to AC Converter (Inverter) • DEFINITION: Converts DC to AC power by switching the DC input voltage (or current) in a pre -determined sequence so as to generate

6 FAQs about [Communication DC to AC Inverter]

What is a DC to AC inverter?

The input voltage, output voltage, frequency and overall power handling depend on the design of the specific device or circuitry. An Uninterruptible Power Supply (UPS) is a typical example of an DC to AC inverter. It provides an alternate electric power supply for connected electronic equipment when the primary power source is not available.

What is a DC to AC converter?

The electrical circuits that transform Direct current (DC) input into Alternating current (AC) output are known as DC-to-AC Converters or Inverters. They are used in power electronic applications where the power input pure 12V, 24V, 48V DC voltage that requires power conversion for an AC output with a certain frequency.

What are the components of a DC to AC inverter?

The circuit diagram of a typical DC to AC inverter consists of several components. The main components include a DC power source (such as a battery or solar panel), an oscillator, a transformer, and a power output stage. The DC power source provides the input voltage for the inverter.

Do I need a DC to AC inverter?

If you’re using a device powered by a DC source (like a battery) and want to plug it into a wall outlet, you’ll need a DC-to-AC inverter. Air Travel: Aircraft often generate DC power, but the onboard electronics, lighting, and other systems typically run on AC power. Inverters are used to make this conversion.

How do inverters convert DC voltage to AC voltage?

Most inverters rely on resistors, capacitors, transistors, and other circuit devices for converting DC Voltage to AC Voltage. In alternating current, the current changes direction and flows forward and backward. The current whose direction changes periodically is called an alternating current (AC). It has non-zero frequency.

Do inverters waste energy converting DC to AC?

IEEE Spectrum, February 6, 2014. Inverters waste energy converting DC power to AC, and there are plenty of other losses in power generation and distribution, so why not simply supply low-voltage DC power to homes to begin with? [PDF] Performance of PV Inverters by Frank Vignola et al. Solar Radiation Monitoring Lab, University of Oregon.

Learn More

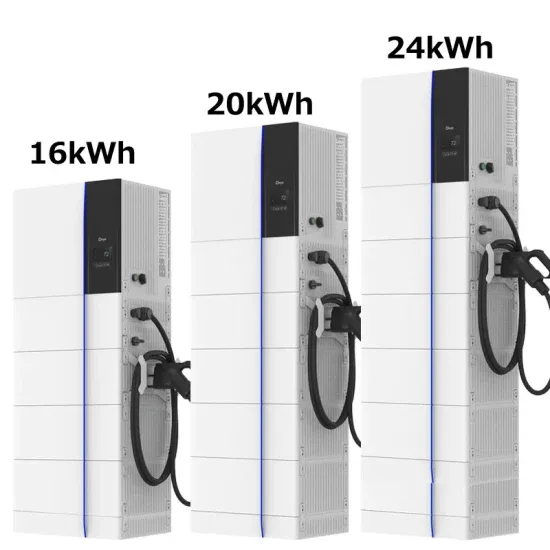

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.