05 DC-AC逆变器(DCAC Converter / Inverter)简

Mar 11, 2023 · 0、概述 并网逆变器(民用) 电动汽车 逆变原理 600伏以下是MOSFET的天下,以上就考虑IGBT出场啦 方波变换 阶梯波变换 多电平更接

DC/AV Inverters · DC/AC Pure Sine Wave Inverters · Schaefer

Schaefer''s broad range of dc-ac pure sine wave inverters, with power ratings from 700W to 45KVA (Parallel for higher output power), feature rugged designs and high reliability while

Power Inverters: What Are They & How Do They

Dec 17, 2019 · Key learnings: Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for

The Complete DC to AC Converter Guide – Renogy US

DC to AC Inverter, also called direct current to alternating current converter or DC to AC Converter, is a necessary tool in building your solar system. In this guide, we''ll tell how DC

High Voltage Solar Inverter DC-AC Kit

Sep 3, 2014 · Many fields use this inverter, such as motor control, UPS, and solar inverter systems. The main function of the inverter is to convert the DC power to AC power by using

How do inverters convert DC electricity to AC?

Mar 6, 2025 · Appliances that need DC but have to take power from AC outlets need an extra piece of equipment called a rectifier, typically built from electronic components called diodes,

How DC-AC Inverters Work and What They Can Be Used For

6 days ago · How DC-AC Inverters Work and What They Can Be Used For In a world increasingly dependent on stable power supply for our devices, the DC-AC inverter plays a critical role.

6 FAQs about [Inverter DC AC]

What is a DC to AC inverter?

The input voltage, output voltage, frequency and overall power handling depend on the design of the specific device or circuitry. An Uninterruptible Power Supply (UPS) is a typical example of an DC to AC inverter. It provides an alternate electric power supply for connected electronic equipment when the primary power source is not available.

What is a DC to AC converter?

The electrical circuits that transform Direct current (DC) input into Alternating current (AC) output are known as DC-to-AC Converters or Inverters. They are used in power electronic applications where the power input pure 12V, 24V, 48V DC voltage that requires power conversion for an AC output with a certain frequency.

How does a DC inverter work?

Converts DC to AC power by switching the DC input voltage (or current) in a pre-determined sequence so as to generate AC voltage (or current) output. Output of the inverter is “chopped AC voltage with zero DC component”. It contain harmonics.

How do inverters convert DC voltage to AC voltage?

Most inverters rely on resistors, capacitors, transistors, and other circuit devices for converting DC Voltage to AC Voltage. In alternating current, the current changes direction and flows forward and backward. The current whose direction changes periodically is called an alternating current (AC). It has non-zero frequency.

What is a DC-AC inverter?

An inverter that converts a direct current into an alternating current is called a DC-AC inverter. However, the term “inverter” generally refers to the equipment that combines an AC-DC converter (that changes an alternating current into a direct current) and a DC-AC inverter so as to be able to generate arbitrary frequencies and voltages. Figure

What is a power inverter?

What is An Inverter? Power inverters convert direct current (DC), the power that comes from a car battery, into alternating current (AC), the kind of power supplied to your home and the power larger electronics need to function. Most cars and motor homes derive their power from a 12-volt battery.

Learn More

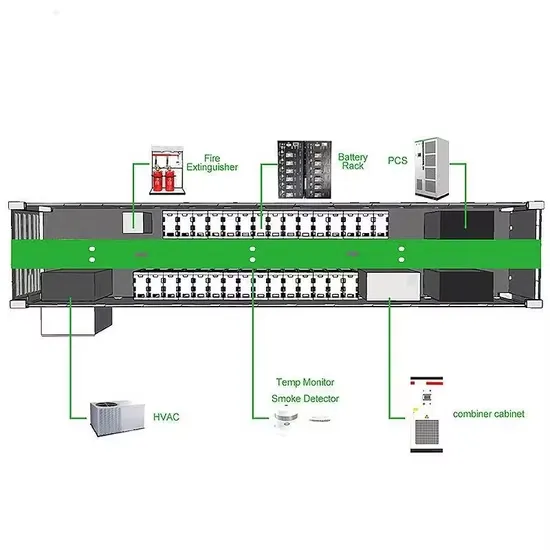

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

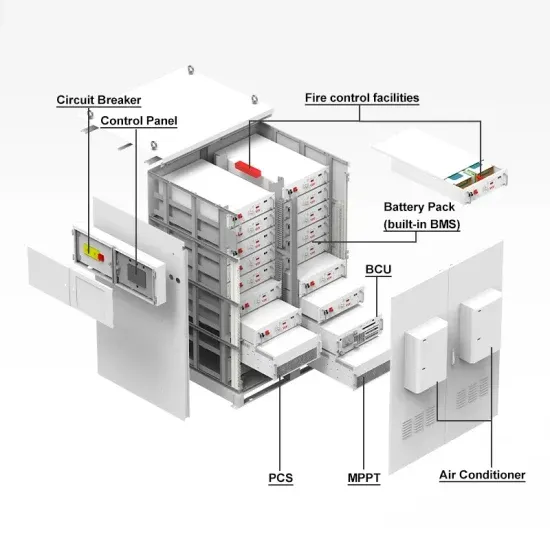

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.