Lightning protection solutions for mobile base stations

Jun 28, 2020 · Most mobile base stations are built on high terrain, such as high mountains, suburbs, and buildings. The base station antennas are often higher than the existing lightning

Protect mobile communication systems | DEHN

Our solutions for lightning and surge protection in the telecommunications sector not only protect equipment, power and data supply, but also – critically – your employees. And with the broad

Lightning Protection Communications Tower

Sep 9, 2018 · GSM communication towers, radio, TV transmitters, forest observation towers, meteorological stations and radars geographic location as of generally lightning compared to

Lightning protection for Telecommunication Stations

Mar 14, 2024 · Lightning protection (strikes with indirect effects) for telecommunication stations by lightning arresters, is applicable for all electrical networks. It is also compulsory to provide

Imagine this: A stormy night in Suzhou, China, where 𝒍𝒊𝒈𝒉𝒕𝒏𝒊𝒏𝒈

Aug 9, 2025 · It''s the ultimate fix for global telecom base stations facing ground faults and leaks, adaptable to any rainy or lightning-heavy region.

Lightning protection, earthing and surge protection of base

Nov 4, 2011 · This paper examines the challenges and solutions in the integration of lightning protection, earthing and surge protection for a base transmission station comprising a telecom

Communication Base Station (Independent Station) Lightning Protection

After four years of theoretical exploration and five years of practical application, improvements have been made in conjunction with the latest protection technology concepts. A new solution

Surge Protection for Cell Sites

Aug 14, 2023 · This is why the standard DIN EN 62305 (IEC 62305) mandates a type 1 lightning current arrester at the boundary between lightning protection zone 0 B and 1. In mobile

Lightning-proof communication base station

The communication base station is the most critical infrastructure in a mobile communication network, most of the existing communication base stations are protected against lightning

Lightning protection, earthing and bonding: Practical

May 1, 2021 · scope: This Recommendation addresses the practical procedures concerning the lightning protection, earthing and bonding of radio base station (RBS) sites. The purpose of

Power Base Stations Lightning Arrestor: Safeguarding Critical

When a single lightning strike can disable power base stations serving 50,000 users, why do 43% of telecom operators still use outdated surge protection? The lightning arrestor – often

Lightning protection solution for telecom communication base stations

May 8, 2025 · Lightning protection for telecom communication base stations involves a multi-layered approach, including direct and indirect lightning strike protection. This includes using

ITU-T Rec. K.97 (02/2014) Lightning protection of

Lightning protection of distributed base stations Summary Recommendation ITU-T K.97 deals with lightning protection of a distributed base station (DBS) on the tower site. A DBS is a new

How Base Station to Be Protected From Lightning

Apr 10, 2020 · The base station can be destroyed totally or some of the equipements to be damaged without proper lighting protection. Then how many ways to protect the base station

The Lightning Protection of Mobile Communication Base

Through investigating the records of new stations struck by lightning, a solution for the problem is proposed and a problem is analyzed in detail. Lightning protection of mobile communication

Lightning introduction pathways and protection measures

Lightning is very destructive. Once a communication base station is struck by lightning, it is easy to cause damage to communication equipment and interrupt communication signals, which will

Lightning protected cable for communication base station

A communication base station and cable technology, which is applied in the field of lightning protection cables for communication base stations, can solve the problems of difficult

ITU-T Rec. K.112 (12/2015) Lightning protection,

Recommendation ITU-T K.112 provides a set of practical procedures related to the lightning protection, earthing and bonding of a radio base station (RBS). It considers two types of RBS:

5 FAQs about [Super capacitor lightning protection solution for communication base stations]

Does a lightning arrester protect a telecommunication station?

Lightning protection (strikes with indirect effects) for telecommunication stations by lightning arresters, is applicable for all electrical networks. It is also compulsory to provide protection against lightning strikes with direct effects by placing a lightning arrester (near the top of the

Who needs lightning protection?

or a large private subscriber / consumer (tertiary industry, others). Lightning protection (strikes with indirect effects) for telecommunication stations by lightning arresters, is applicable for all electrical networks.

How to protect against indirect lightning strikes on electrical networks?

Protection against indirect lightning strikes on electrical networks must be treated globally. ABB Soulé offers a complete range of lightning arresters adapted to this approach. They must be used in accordance with standard practice with a ground network optimized by earthing (low impedance).

What is the resistance of a lightning earthing connector?

The resistance of the lightning earthing connector must be less than 10 ohms. Appropriate inspection equipment will be used to check this resistance at the time of installation and after, during a maintenance operation (contract).

How much protection does a lightning conductor need?

It depends on the initiation advance T of the OPR measured in the high voltage Laboratory, on the levels of protection I, II, III calculated according to the lightning risk assessment guide (Appendix B of the French standard NF C 17-102) and the height h of the lightning conductor over the area to be protected (minimum height = 2m). NF C 17-102.

Learn More

- Kit plus super capacitor for building communication base stations

- Regulations on lightning protection and grounding of wind power in communication base stations

- South Ossetia communication base station wind and solar complementary lightning protection grounding manufacturer supply

- Monaco Communication Base Station Super Capacitor Cabinet

- Hybrid energy high temperature solution for communication base stations

- Tonga Communication Base Station Super Capacitor Photovoltaic Power Generation Manufacturer

- Moroni Communication Base Station Battery Energy Storage System Lightning Protection Grounding

- Lightning Protection Communication Base Station

- Communication green base station carries out lightning protection

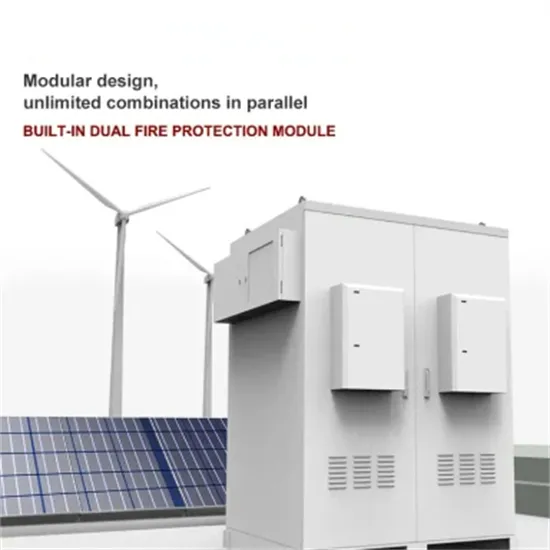

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.