Lightning protection, earthing and bonding: Practical

May 1, 2021 · This Recommendation addresses the practical procedures concerning the lightning protection, earthing and bonding of radio base station (RBS) sites. The purpose of this

Basics of Lightning Protection for Communication Towers

Oct 11, 2021 · For lightning protection best resources are Polyphasers book the ARRL Handbook along with the book "Grounding and Bonding for the Radio Amateur". The ARRL Handbook

A Guide to BS EN 62305 Protection Against Lightning

Sep 19, 2023 · To provide an introduction to the transient overvoltage protection requirements defined within BS 7671. To outline the importance of lightning protection component

(PDF) Lightning protection scenarios of communication

This paper provides comprehensive analysis on the lightning protection scenarios in 48 communication and broadcasting towers situated in similar isokeraunic contours in Sri Lanka

Lightning Protection Strategies for Ground-mounted PV

Sep 7, 2024 · The present standard in the field of lightning protection is based on the four-part series of the IEC 62305 standard and the relevant national guidelines, which present an

Technical Basis for Regulatory Guidance on Lightning

Jun 14, 2023 · With the advent of digital and low-voltage analog systems in NPPs, lightning protection is becoming increasingly important. These systems have the potential to be more

Technical requirements for lightning protection and grounding

Here we introduce the technical requirements for the C network mobile base station lightning protection grounding installation project. 1 General technical requ

Lightning and surge protection for wind turbines

May 22, 2024 · Lightning protection (LP) for a wind turbine consists of an ex-ternal lightning protection system (LPS) and surge protection measures (SPMs) for protecting electrical and

Lightning protection scenarios of communication tower

Dec 6, 2023 · Keywords: Lightning Protection Safety Communication Tower Guidelines Grounding and broadcasting towers situated in similar isokeraunic contours in Sri Lanka at 79 –81 East

Lightning protection, earthing and surge protection of base

Dec 22, 2011 · An effective lightning protection design for a telecommunication facility requires an integrated approach to a number of key factors: Protection against direct

ITU-T Rec. K.120 (12/2016) Lightning protection and

Lightning protection and earthing of a miniature base station Summary Recommendation ITU-T K.120 provides guidelines for lightning protection and earthing of miniature base stations. A

通信基站防雷设计与接地方案分析-通信学论文-论文网

Dec 15, 2016 · This paper discusses the recurring problems of communication base station lightning protection and grounding systems, combined with many years of experience in

ITU-T Rec. K.112 (07/2019) Lightning protection,

Recommendation ITU-T K.112 provides a set of practical procedures related to the lightning protection, earthing and bonding of radio base stations (RBSs). It considers two types of RBS:

Lightning Protection Grounding Solutions for

6 days ago · 12 Lightning Protection & Grounding Solutions for Communication Sites Conductors from the tower legs to the radial system must have low inductance (large circumference) to

research on lightning protection and grounding safety

Download Citation | On May 27, 2022, Huan Huang and others published research on lightning protection and grounding safety evaluation of base station shared power tower | Find, read

防雷接地规范(Lightning protection grounding code)

Aug 4, 2017 · prevent lightning. Lightning protection and grounding of 5 other facilities Lightning protection device for preventing thunder sound and inhibit the two lightning 1 mobile

Grounding System Design for Wind Power Generation

Oct 16, 2024 · Abstract Human safety is the most important factor to determine any grounding system, therefore low-frequency grounding resistance (LFGR) of wind power generation

Lightning protection scenarios of communication tower

Dec 1, 2011 · This paper provides comprehensive analysis on the lightning protection scenarios in 48 communication and broadcasting towers situated in similar isokeraunic contours in Sri

6 FAQs about [Regulations on lightning protection and grounding of wind power in communication base stations]

How should a lightning protection System (RBS) be formed?

The earthing network of an RBS should be formed by a ring loop surrounding the tower, equipment room and fence, at a minimum. The mean radius re of this ring loop should be not less than l1, as indicated in Figure 1 and this value depends on the lightning protection system (LPS) class and on the soil resistivity.

Does BS 6651 apply to lightning protection earthing?

BS 6651 was quite clear in its methodology statement relating to the testing of the lightning protection earthing system surrounding a building. Unfortunately, in BS EN 62305-3 clause E.7.2.4, we believe this to be somewhat vague in its intent.

How should a lightning protection system (LPS) be connected?

These individual elements of an LPS should be connected together using appropriate lightning protection components (LPC) complying with BS EN 50164 or IEC 62561 series. This will ensure that in the event of a lightning current discharge to the structure, the correct design and choice of components will minimize any potential damage.

How can a lightning strike be prevented?

A direct lightning strike must be prevented if at all possible. This can typically be achieved by ensuring that external equipment is within a zone of protection and where necessary is bonded to the structural lightning protection.

What is a lightning protection system?

Electrical discharge due to lightning, which causes physical damage in the structure to be protected. Part of an external Lightning Protection System which is intended to conduct lightning current from the air termination system to the earth termination system. Lightning flash initiated by a downward leader from cloud to earth.

How do you protect a building from lightning?

This can typically be achieved by ensuring that external equipment is within a zone of protection and where necessary is bonded to the structural lightning protection. For example CCTV cameras should be safely positioned within the zone of protection provided by the structure’s lightning protection.

Learn More

- South Ossetia communication base station wind and solar complementary lightning protection grounding manufacturer supply

- Which departments are involved in wind power in Bahrain communication base stations

- What is wind power used for communication base stations

- Fire protection requirements and standards for wind and solar hybrid communication base stations

- Adjustment scope of wind power construction for communication base stations

- Does Moldova have communication base stations and wind power

- Maintenance plan for wind power and photovoltaic power generation at communication base stations

- The role of wind power in network communication base stations

- Moroni Communication Base Station Battery Energy Storage System Lightning Protection Grounding

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

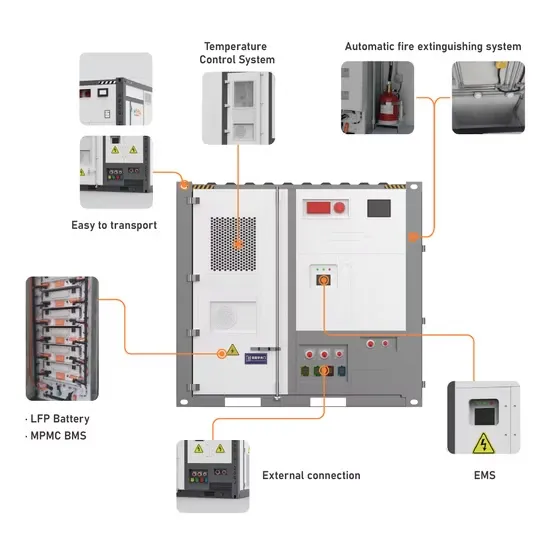

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.