(PDF) Analysis of Lightning Protection and Grounding Effect

Aug 26, 2020 · By analyzing the lightning protection and grounding requirements of the respective systems of the communication base station and the power tower, the impact of the towers on

Lightning Protection Solutions | nVent ERICO

4 days ago · We make safe, reliable and high-quality solutions for every spec and project. Lightning protection needs vary according to each specific facility. The requirements of

R16AN0049EU: Importance of Grounding in Battery

Jul 2, 2024 · Grounding considerations for Battery Management Systems (BMS) in battery-operated environments are crucial for ensuring safety, functionality, and accurate battery

Lightning protection and grounding scheme for communication base station

Because the environment and construction methods of each base station are different, the lightning protection and grounding of the base station cannot be generalized. Lightning

Energy storage system: Current studies on batteries and power

Feb 1, 2018 · The paper summarizes the features of current and future grid energy storage battery, lists the advantages and disadvantages of different types of batteries, and points out

Protection against surges and overvoltages in Battery

Feb 16, 2022 · BESS systems contain AC/DC converters and battery banks implemented in concrete constructions or in metallic containers. These AC/DC converters have sensitive

Communication Base Station (Independent Station) Lightning Protection

"Wireless communication base station lightning intrusion channel isolation protection technology" in the practical application of the project, the use of "simple network" with Shenzhen

Power Base Stations Grounding System | HuiJue Group E-Site

As 5G deployment accelerates globally, power base stations grounding systems face unprecedented challenges. Did you know that 23% of telecom outages in 2023 stemmed from

R16AN0049EU: Importance of Grounding in Battery

Jul 2, 2024 · Importance of Grounding in Battery Management Systems This application note explores the crucial role of grounding in battery management systems (BMS). It starts with

research on lightning protection and grounding safety

May 29, 2022 · Building 5g base station on power tower is an effective way to realize resource integration and save national resources. However, the voltage level and installe

NEC Standards & Lightning Protection Guidelines | ES Grounding

6 days ago · Discover NEC standards for lightning protection and NFPA 780 guidelines. Learn about lightning protection system requirements and code compliance

Lightning protection and grounding scheme for communication base station

The lightning protection grounding project should be implemented according to local conditions, and the base station grounding system should be designed according to the principle of

Lightning protection, earthing and surge protection of base

Dec 22, 2011 · An effective lightning protection design for a telecommunication facility requires an integrated approach to a number of key factors: Protection against direct lightning strikes;

A Guide to BS EN 62305 Protection Against Lightning

Sep 19, 2023 · A Guide to BS EN 62305 Protection Against Lightning 3rd edition Guide to BS 62305 3rd edition Cover 08/01/2014 09:49 Page 2 Furse is the market leading lightning

Lightning surge analysis for hybrid wind turbine-photovoltaic-battery

Dec 1, 2023 · The lightning transient overvoltages in the hybrid wind turbine (WT) -photovoltaic (PV)- battery energy storage system (BESS) is investigated in this

White Paper: Best Practices for Lightning

Feb 5, 2025 · Lightning strikes present a serious threat to critical facilities, leading to costly downtime, hazardous working conditions, and potentially irreversible

Lightning protection on photovoltaic systems: A review on

Feb 1, 2018 · In many countries, solar photovoltaic (PV) systems are regarded as one of the best renewable energy (RE) sources in terms of cost of installation, return of investment (ROI),

Grounding for Lightning Protection Systems

Jan 5, 2023 · The objective of lightning protection is to preclude hazards to persons, structure, or buildings and their contents attributable to the effects of lightning. Protection measures to

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Lightning surge analysis for cascaded H-bridge converter-based battery

Jan 1, 2025 · The lightning overvoltage in the cascaded H-bridge converter-based battery energy storage system (CHBC-BESS) is investigated in this paper. The high f

Protection against surges and overvoltages in Battery

Feb 16, 2022 · The purpose of this paper is to illustrate when and where the installation of surge protective devices (SPDs) is required in Battery Energy Storage Systems (BESS). BESS

6 FAQs about [Moroni Communication Base Station Battery Energy Storage System Lightning Protection Grounding]

Why do battery energy storage systems need grounding and bonding?

For grid-scale battery energy storage systems (BESS), grounding and bonding is essential for safety and performance. The goal of grounding and bonding is to achieve customer-targeted resistance levels. These low resistance levels allow fault currents to easily discharge into the ground, protecting people, equipment and the BESS itself.

Why is grounding important in battery management systems (BMS)?

Grounding in Battery Management Systems (BMS) is crucial for ensuring voltage and current measurement accuracy. Accurate voltage measurements depend on a stable ground reference. If the BMS ground is improperly connected or affected by noise, voltage readings can become distorted.

What is a good grounding for a BMS?

Proper grounding of communication interfaces such as CAN or LIN is also crucial, aligning with relevant standards to ensure reliable external communication. Grounding should address static discharge protection to safeguard sensitive BMS components.

Why is grounding a BMS enclosure important?

Grounding the BMS enclosures, such as control boxes, is also important. Metal enclosures can function as Faraday cages, shielding internal components from external static charges. Using grounding wires or straps to connect components to the ground plane ensures low-resistance connections, enhancing ESD protection.

What is EMC grounding?

Unlike safety grounding, EMC grounding does not always connect to earth ground; it often involves shielding or conductive planes to mitigate EMI. EMI arises when electronic circuits interact with external electromagnetic fields, disrupting normal operations and compromising power quality.

Why is low-resistance grounding important?

Low-Resistance Grounding ‒ Reducing ground resistance helps minimize voltage drop across the shunt resistor, which is crucial for accurate current measurement. By ensuring low-resistance grounding, the integrity of voltage measurements is maintained, leading to more reliable battery monitoring and management.

Learn More

- Battery energy storage system grounding wire for communication base station

- Battery energy storage system for Icelandic Environmental Protection Agency s communication base station

- Sana a 5G communication base station battery energy storage system HJ Communication

- Hybrid power supply of battery energy storage system for Saint Lucia communication base station

- Construction quotation of battery energy storage system for communication base station

- Communication base station battery energy storage system commissioning worker

- The composition of the battery energy storage system of 5g communication base station

- The temperature of the battery energy storage system of the outdoor communication base station is too high

- Montevideo Integrated Communication Base Station Battery Energy Storage System Maintenance

Industrial & Commercial Energy Storage Market Growth

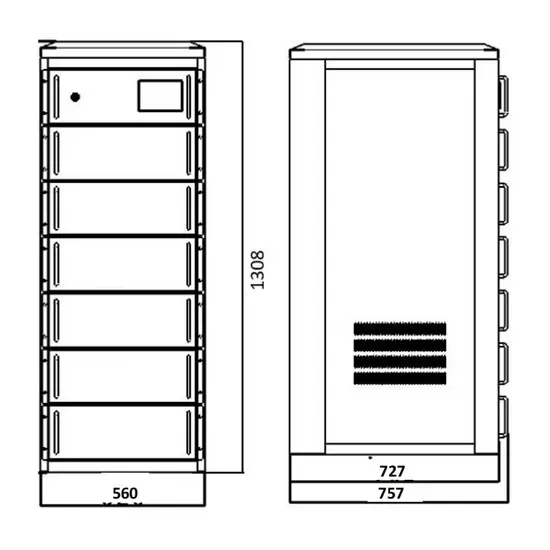

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.