Installation and commissioning of energy storage for

The one-stop energy storage system for communication base stations is specially designed for base station energy storage. Deployment :Modular design enables quick disassembly and

Communication Base Station Energy Storage Battery

Apr 3, 2025 · The communication base station energy storage battery market is experiencing robust growth, driven by the increasing demand for reliable and uninterrupted power supply for

Commissioning and Maintenance Processes for Energy Storage Systems

Nov 22, 2024 · As renewable energy continues to grow rapidly, energy storage systems are becoming an essential part of modern power systems. Proper commissioning and

Commissioning and Maintenance Processes for Energy Storage Systems

Nov 22, 2024 · Proper commissioning and maintenance are critical to ensure these systems operate safely, reliably, and efficiently. Heres a detailed guide to the key processes involved in

Strategy of 5G Base Station Energy Storage Participating in the Power

Mar 13, 2023 · The proportion of traditional frequency regulation units decreases as renewable energy increases, posing new challenges to the frequency stability of the power system. The

Commissioning Engineer, Battery Energy Storage

Onsite for Commissioning and Acceptance Testing of Balance of Plant equipment including electrical systems such as, Switchgear, relay protection, metering, MV/LV transformers, and

Communication network cabinet system energy storage battery commissioning

Commissioning Manager – 5 years'''' experience with renewable energy (Solar Utility Scale) and/or Energy Storage System, Power System Design, Communication Network, and minor

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · A multi-base station cooperative system composed of 5G acer stations was considered as the research object, and the outer goal was to maximize the net profit over the

Communication Base Station Energy Storage | HuiJue Group

Why Energy Storage Is the Missing Link in 5G Expansion? As global 5G deployments accelerate, operators face a paradoxical challenge: communication base station energy storage systems

Energy storage system of communication base station

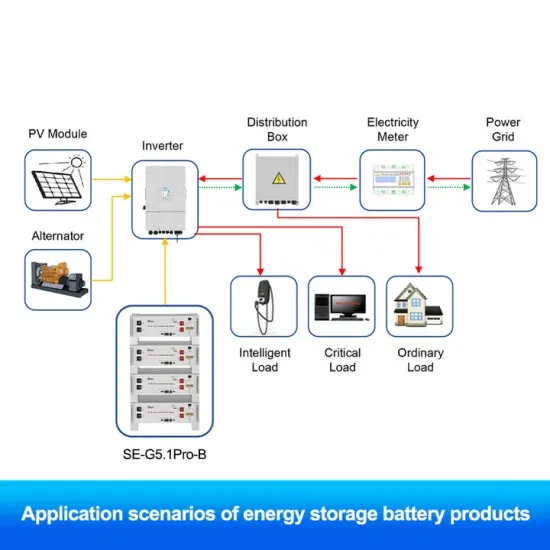

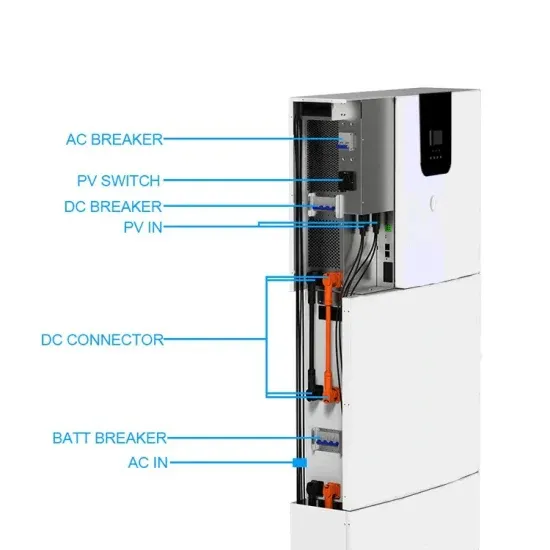

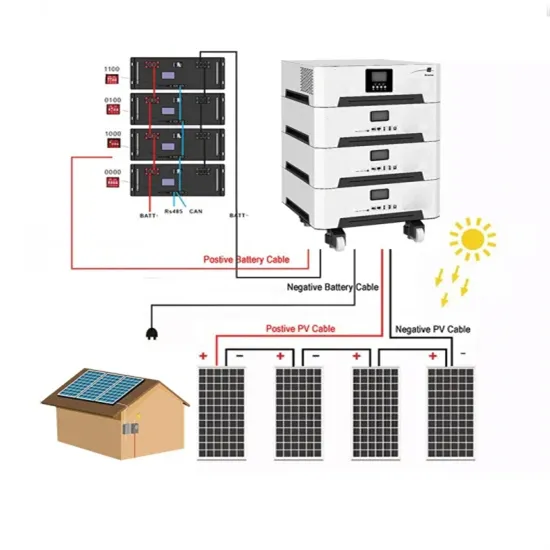

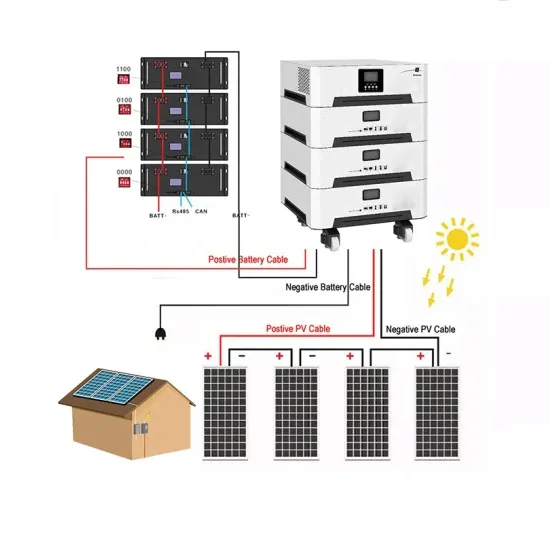

The Energy storage system of communication base station is a comprehensive solution designed for various critical infrastructure scenarios, including communication base stations, smart

EES Station Commissioning: Procedures & Safety

Oct 22, 2024 · Commissioning content includes testing battery array insulation resistance, cooling/heating systems, battery management system insulation

Battery commissioning for energy storage power station

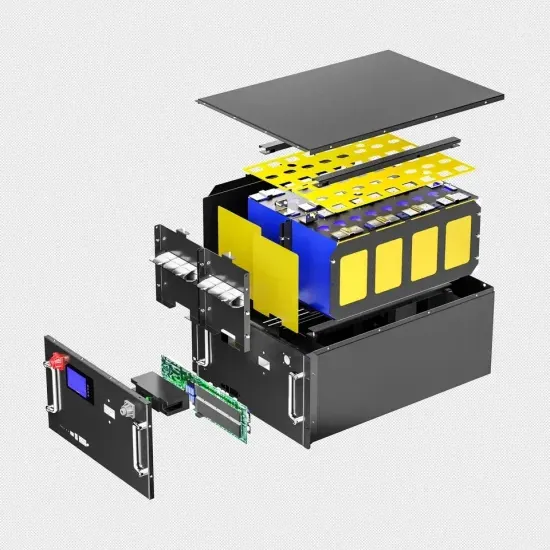

What is battery energy storage system (BESS)? You have full access to this open access article Battery energy storage system (BESS) is one of the effective technologies to deal with power

The BESS System: Construction, Commissioning, and O&M

3 days ago · The energy storage inverter (PCS), battery management system (BMS), and energy management system (EMS) have powered up and completed single commissioning.

Commissioning Energy Storage

Aug 27, 2019 · The value of commissioning is to insure proper operation of the energy storage system, safety systems, and ancillary systems. ALSO, Commissioning is an excellent means

Energy Storage in Telecom Base Stations: Innovations

With the relentless global expansion of 5G networks and the increasing demand for data, communication base stations face unprecedented challenges in ensuring uninterrupted power

Communication Base Station Energy Storage Lithium Battery

Jun 30, 2025 · The future of the global communication base station energy storage lithium battery sales market looks promising with opportunities in the communication base station, hospital,

BESS Commissioning: The Critical Pathway to Energy Storage

With global energy storage capacity projected to reach 1.6 TWh by 2030 (BloombergNEF), BESS commissioning emerges as the make-or-break phase determining project viability. Why do

What is the purpose of batteries at telecom base

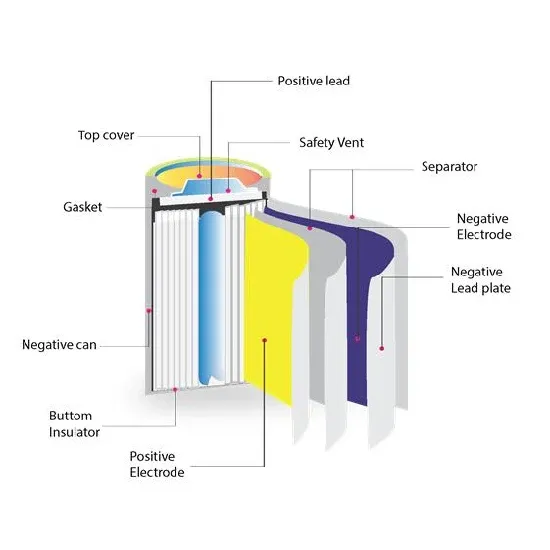

Feb 10, 2025 · The lead storage battery is the most widely used energy storage battery in the current communication power supply. Among the many types of

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, such as solar and wind,

cairo communication base station energy storage battery

Lithium battery is the magic weapon for communication base station energy storage system and power container energy storage China''''s communication energy storage market has begun to

6 FAQs about [Communication base station battery energy storage system commissioning worker]

What is Bess ion & energy and assets monitoring?

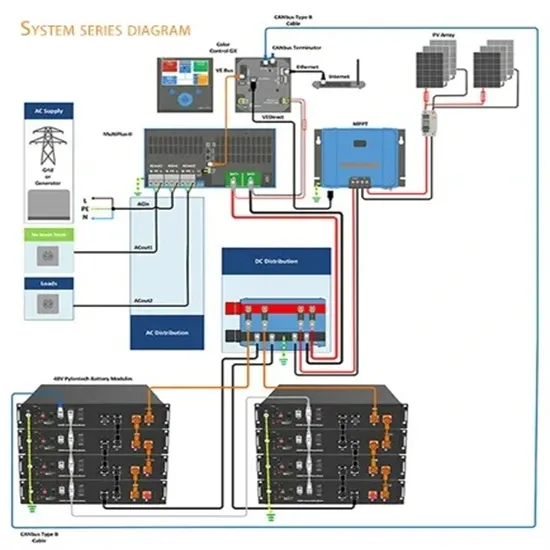

ion – and energy and assets monitoring – for a utility-scale battery energy storage system BESS). It is intended to be used together with additional relevant documents provided in this package.The main goal is to support BESS system designers by showing an example desi

What happens during energy storage project commissioning?

During energy storage project commissioning, every team involved feels the heat: For the EPC (Engineering Procurement and Construction) team, it’s their final stretch of construction and they’re eager to finish.

What is a battery energy storage system (BESS) e-book?

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this document comes from Sinovoltaics’ own BESS project experience and industry best practices.

What are the requirements for a battery management system (BMS) handover test?

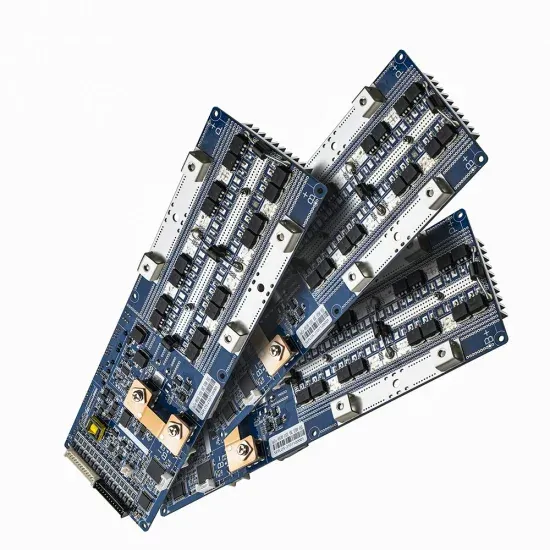

Energy Storage Battery Management System (BMS) Handover Test The BMS single commissioning should meet the following requirements: BMS collects the battery voltage in real-time. BCU collects the terminal voltage of the battery pack in real-time.

What is a commissioning phase?

COMMISSIONING Commissioning phase is one of the most critical phases of the BESS’ supply process. It marks the of- cial transition from a factory to a customer owned and operated BESS. “Commissioning helps ensure that a system was correctly designed, installed and tested.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

Learn More

- Is the battery energy storage system of the communication base station waterproof

- Malawi communication base station battery energy storage system planning

- Dominica Aviation Tower Communication Base Station Battery Energy Storage System Project

- Algiers communication base station flow battery energy storage

- The company that provides battery energy storage system equipment for Paramaribo communication base station

- Gaborone Communication Base Station Battery Energy Storage System New Communication

- What is the process for replacing the battery energy storage system of a communication base station

- Wind power method of battery energy storage system for Naypyidaw communication base station

- Magadan communication base station battery energy storage system environmentally friendly electricity

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.