A systematic review and comparison of liquid-based cooling

Jul 1, 2023 · The battery thermal management system (BTMS) is arguably the main component providing essential protection for the security and service performance of lithium-ion batteries

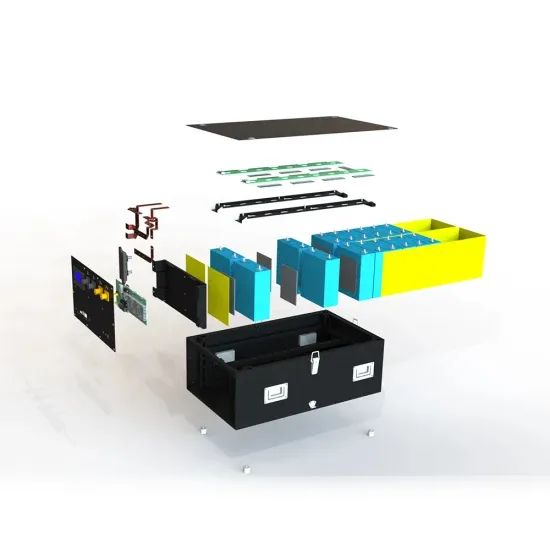

What are the energy storage liquid-cooled battery modules?

Jun 17, 2024 · Energy storage liquid-cooled battery modules are specialized systems designed to store large amounts of electrical energy efficiently, utilizing liquid cooling for temperature

Fire protection design of a lithium-ion battery warehouse

Dec 1, 2022 · The research on the traditional warehouse is relatively mature, but there is still a lack of research on the fire risk and fire protection measures of LIB warehouses and other

Advances in flow pattern design of liquid-cooled components for battery

Feb 1, 2025 · The liquid-cooled component is a key part of liquid-cooled thermal management system, which controls the temperature of batteries to ensure safety and high performance of

Lay_Out_Guideline_v7 dd

Mar 1, 2022 · As such early and reliable fire detection is a must when designing fire protection systems for Lithium-Ion battery systems. However, the environment in which the batteries are

A state-of-the-art review on numerical investigations of liquid-cooled

Nov 10, 2024 · The battery thermal management system (BTMS) is an essential part of an EV that keeps the lithium-ion batteries (LIB) in the desired temperature range. Amongst the different

Liquid-cooled container energy storage system single set

How many battery cells are in a ENERC liquid cooled container? tery system is composed of 10 battery racks in parallel. Each battery rack contains 8 battery modules by series

Electric-controlled pressure relief valve for enhanced safety in liquid

Mar 1, 2024 · The liquid-cooled battery energy storage system (LCBESS) has gained significant attention due to its superior thermal management capacity. However, liquid-cooled battery

Marioff HI-FOG Fire protection of Li-ion BESS Whitepaper

Mar 7, 2025 · A fixed firefighting system does not stop an already occurring thermal runaway sequence within a battery module, but it can prevent fire spread from module to module, or

Study of Cooling Performance of Liquid-Cooled EV Battery Module

Dec 2, 2024 · This study examines the coolant and heat flows in electric vehicle (EV) battery pack that employs a thermal interface material (TIM). The overall temperature distribution of the

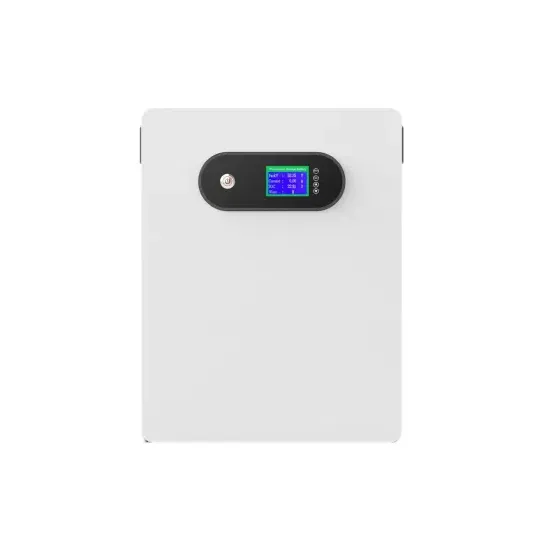

C&I liquid-cooled outdoor energy storage cabinet

Safe & Endurable Robust electrical systems and fire-resistant materials for high-temperature and high-pressure tolerance. High Protection Level Our outdoor cabinet is IP66 constructed in a

Comprehensive comparison study on battery thermal management modules

Jun 1, 2025 · Furthermore, there is a substantial lack of experimental comparisons between indirect liquid cooling (liquid cooling plates) and direct liquid cooling (immersed cooling)

A gradient channel-based novel design of liquid-cooled battery

Apr 1, 2022 · Liquid-cooled battery thermal management system (BTMS) is significant to enhance safety and efficiency of electric vehicles. However, the temperature gradient of the coolant

Fire protection design of a lithium-ion battery warehouse

Dec 1, 2022 · In this study, the fire dynamics software (FDS) is used to simulate different fire conditions in a LIB warehouse numerically and determine the optimal battery state of charge

L3 LimitLess Lithium Series Battery Energy Storage System

Jul 15, 2024 · Module Level – For L3 HV and L3 HVR: Contained in each battery module is a 12-gram aerosol agent canister (shown in Fig 1) with a thermal deployment mechanism which

Eaton battery solutions brochure

Apr 15, 2025 · The IBC-SW cabinet is our newest and smallest battery cabinet of-fering, with one large string of batteries inside. This welded cabinet offers flexibility in adding runtime with a

Liquid-cooled energy storage battery cabinet assembly

The ST2752UX liquid-cooled battery cabinet, with a maximum capacity of 2752kWh, includes a liquid cooling unit, 48 battery modules (64 cells per module), 4 DC/DC (0.25C, 4 hours system)

A review of lithium ion battery failure mechanisms and fire

Jul 1, 2019 · Lithium ion batteries (LIBs) are booming due to their high energy density, low maintenance, low self-discharge, quick charging and longevity advantage

Marioff HI-FOG Fire protection of Li-ion BESS Whitepaper

Mar 7, 2025 · An overview is provided of land and marine standards, rules, and guidelines related to fixed firefighting systems for the protection of Li-ion battery ESS. Both battery technology

Progress on the research of fire behavior and fire protection of

Mar 1, 2021 · The fire behavior of high energy LIB is exhibited, and the TR propagations between cells and modules are discussed. This paper introduces the warning parameters and

Unveiling the Industrial and Commercial Liquid-Cooled

Mar 7, 2025 · The Energy Management System (EMS) and Battery Management System (BMS) work in tandem to monitor the overall status of the cabinet 24/7, including the battery, liquid

Full-scale experimental study on suppressing lithium-ion battery

May 1, 2022 · Effective and prompt fire-fighting methods for dealing with EV fires are required. A fire protection method referred to as electric vehicle fire enclosure (EVFE) was proposed in

6 FAQs about [How many fire protection modules are there in the liquid-cooled battery cabinet ]

How do you protect a battery module from a fire?

The most practical protection option is usually an external, fixed firefighting system. A fixed firefighting system does not stop an already occurring thermal runaway sequence within a battery module, but it can prevent fire spread from module to module, or from pack to pack, or to adjacent combustibles within the space.

Should a fire module/cabinet contain water?

Water has superior cooling capacity, is plentiful (in many areas), and is easy to transport to the seat of the fire. While water might be the agent of choice, the module/cabinet configuration could make penetration of water dificult for cooling the area of origin but might still be efective for containment.

What are the key variables of fire protection in a Lib warehouse?

Based on the idea of modeling presented in the aforementioned study and the results of field investigation on a warehouse of a LIB factory, this paper intends to use numerical simulation to analyze the key variables of fire protection in a LIB warehouse in Nanjing, China, such as battery SOC, shelf spacing, and automatic fire extinguishing system.

How many battery cells are in a battery cabinet?

Each battery cabinet is with 240 battery cells in series with contactor, detective unit, sampling line, battery management systems, fuse, etc. BESS employs a sophisticated, multilevel battery management system (BMS) for system monitoring and control. Each battery management system including:

How many temperature detectors does a battery module have?

internally to prevent short circuit to ensure the electrical safety of the battery module. Each battery module has 16 temperature detectors. Power Conditioning System (SP100ELL) is a bi-directional conversion system to convert power between static energy storage and grid or load with add-on features of power quality management.

Do li-ion batteries need fire protection?

Marine class rules: Key design aspects for the fire protection of Li-ion battery spaces. In general, fire detection (smoke/heat) is required, and battery manufacturer requirements are referred to in some of the rules. Of-gas detection is specifically required in most rules.

Learn More

- How to install lithium iron phosphate battery station cabinet

- How to connect the reserved power supply in the empty battery cabinet

- How to calculate power and current in battery cabinet

- How big a battery cabinet can be placed in the center box

- How much is the price of outdoor communication battery cabinet in the Netherlands

- How to change the lithium battery station cabinet to photovoltaic power supply

- How to assemble the battery cabinet in the computer room

- How to assemble the c16 battery cabinet

- How to connect 32 batteries in a UPS battery cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.