Design of Motor/Generator for Flywheel Batteries

Oct 2, 2020 · This article presents the design of a motor/generator for a flywheel energy storage at household level. Three reference machines were compared by means of finite element

Case study on flywheel energy storage systems: LPTN-based

Jun 1, 2025 · This study established a lumped parameter thermal network model for vertical flywheel energy storage systems, considering three critical gaps in conventional thermal

Theoretical Contribution to multiphysical modeling of flywheel energy

Abstract This paper gives a theoretical contribution to the multiphysical modeling of Flywheel Energy Storage Systems. In this work, a laboratory prototype of a flywheel consisting of a

Comprehensive Analysis and Comparation of Performance of a Flywheel

Oct 31, 2021 · In this paper, based on the dual three-phase Permanent Magnetic Synchronous Motor (PMSM), an MW-level flywheel energy storage system (FESS) is proposed. The mot

Charging-Discharging Control Strategies of Flywheel Energy Storage

Mar 23, 2023 · Charging-Discharging Control Strategies of Flywheel Energy Storage Based on a Dual Three-Phase Permanent Magnet Synchronous Motor March 2023 DOI:

Design and application of electromechanical flywheel hybrid

Nov 1, 2022 · The electromechanical flywheel hybrid power device has the dual attributes of energy supply and power output, which can provide more design space for the optimization of

Sensorless fault-tolerant control strategy of flywheel energy storage

Flywheel energy storage systems (FESS) are crucial for efficient energy storage in power systems. However, the sensorless control strategy for flywheel motors can experience speed

Study of Flywheel Energy Storage in a Pure EV Powertrain in

Apr 6, 2021 · Study of Flywheel Energy Storage in a Pure EV Powertrain in a Parallel Hybrid Setup and Development of a Novel Flywheel Design for Regeneration Efficiency Improvement

A novel flywheel energy storage system: Based on the barrel

Nov 1, 2021 · Download Citation | A novel flywheel energy storage system: Based on the barrel type with dual hubs combined flywheel driven by switched flux permanent magnet motor | With

Optimization strategy for braking energy recovery of electric

Dec 10, 2024 · Braking energy recovery (BER) notably extends the range of electric vehicles (EVs), yet the high power it generates can diminish battery life. This paper proposes an

清华大学学位论文服务系统

May 23, 2024 · The inertia flywheel adopts doubly fed induction motor to meet the high inertia support requirements of power grid; The high-speed flywheel adopts permanent magnet

Research on control strategy of flywheel energy

Nov 30, 2023 · The literature 9 simplified the charge or discharge model of the FESS and applied it to microgrids to verify the feasibility of the flywheel as a

Dual‐inertia flywheel energy storage system for electric

Nov 13, 2024 · Managing the high‐rate‐power transients of Electric Vehicles (EVs) in a drive cycle is of great importance from the battery health and drive range aspects. This can be achieved

A review of control strategies for flywheel energy storage

Nov 1, 2022 · The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

A Flywheel Energy Storage System with Active Magnetic

Jan 1, 2012 · A flywheel energy storage system (FESS) uses a high speed spinning mass (rotor) to store kinetic energy. The energy is input or output by a dual-direction motor/generator.

Introduction to motors and controllers of flywheel energy storage

Abstract: This paper introduces flywheel energy storage system (FESS) with particular focus on motors and controllers. The paper covers the principle and characteristics of permanent

Design of an improved adaptive sliding mode observer for

Apr 28, 2025 · Accordingly, an improved adaptive sliding mode observer algorithm for the charging and discharging control of the flywheel energy storage system is proposed.

A novel flywheel energy storage system: Based on the barrel

Nov 1, 2021 · Flywheels store excess electrical energy in the form of kinetic energy via a rotating mass. Metal-organic frameworks and carbon nanotubes store potential energy in their

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

FLYWHEEL ENERGY STORAGE SYSTEM AND IT''S

May 4, 2020 · Abstract: Flywheel has been in use since long time for storing energy and other applications. The basic steps in flywheel energy storage system (FESS) are to convert the

Control strategy of MW flywheel energy storage system

Nov 1, 2022 · The implementation of the "dual carbon" goal, nationally in China, has accelerated the profound transformation of the energy industry, and the development and utilization of

Design, modeling, and validation of a 0.5 kWh flywheel energy storage

Nov 1, 2024 · The flywheel energy storage system (FESS) has excellent power capacity and high conversion efficiency. It could be used as a mechanical battery in the

Energy storage flywheel electromagnetic field

Flywheel energy storage systems: A critical review on technologies, applications, and future prospects This structure is a combination of the rotor''''s energy storage parts and

3 FAQs about [Flywheel energy storage dual motor]

What is a compact and highly efficient flywheel energy storage system?

Abstract: This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss caused by the flux of permanent magnetic machines. A novel compact magnetic bearing is proposed to eliminate the friction loss during high-speed operation.

Can a high-speed flywheel energy storage system utilise the fess useable capacity?

This can be achieved by high power-density storage, such as a high-speed Flywheel Energy Storage System (FESS). It is shown that a variable-mass flywheel can effectively utilise the FESS useable capacity in most transients close to optimal. Novel variable capacities FESS is proposed by introducing Dual-Inertia FESS (DIFESS) for EVs.

How does a dual inertia motor work?

The proposed DIFESS has dual inertias, mounted on a common shaft of the motor/generator (M/G) set, as shown in Figure 1. The first inertia (Ifly1) is fixed on the shaft, while the second inertia (Ifly2) can either be engaged or rotate freewheeling using a clutch.

Learn More

- Ashgabat Motor Flywheel Energy Storage

- Porto Novo is a flywheel energy storage motor

- Flywheel energy storage application in wind power generation

- Flywheel energy storage magnification

- Flywheel Energy Storage Payback Cycle

- Guatemala communication base station flywheel energy storage photovoltaic power generation capacity

- Irish Micro-Controlled Flywheel Energy Storage Company

- Advantages and disadvantages of flywheel energy storage UPS

- Supercapacitor flywheel energy storage

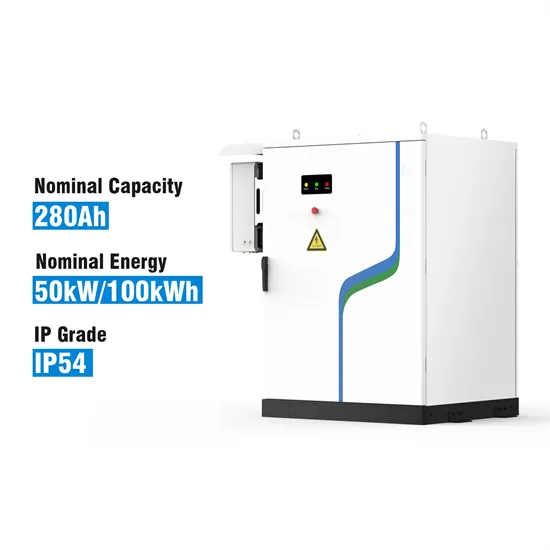

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

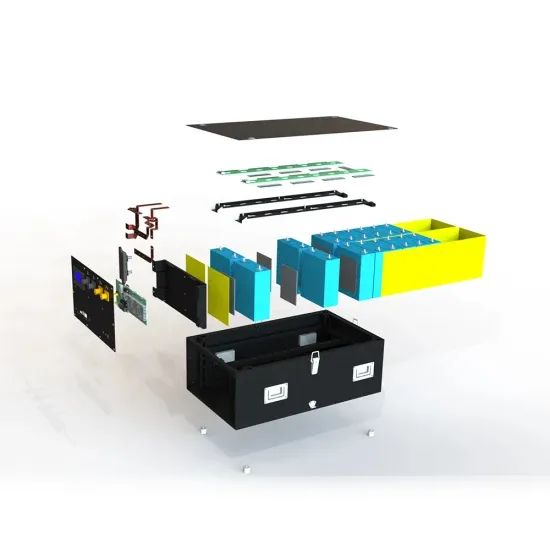

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.