A review of flywheel energy storage systems: state of the

Mar 15, 2021 · 00-01 99-00 Keywords: and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There

Active power control of a flywheel energy storage system for wind

Jan 9, 2012 · The integration of wind power generation in power systems is steadily increasing around the world. This incorporation can bring problems onto the dynamics of power systems

A review of energy storage technologies for wind power applications

May 1, 2012 · The main objectives of the article are the introduction of the operating principles, as well as the presentation of the main characteristics of energy storage technologies suitable for

Hybrid flywheel-battery storage power allocation strategy

Jul 22, 2025 · To address this issue, this paper proposes a hybrid energy storage-based power allocation strategy that combines flywheel and battery storage systems to smooth wind power

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Review of flywheel energy storage systems for wind power applications

This paper introduces the background of the use of FES in wind power, explains the principles of FES, and reviews current status in the control strategies of FES. Key words: flywheel energy

Research on frequency modulation application of

Aug 24, 2022 · This paper mainly introduces the background of wind power generation frequency modulation demand, the main structure and principle of energy storage flywheel system and

Review of flywheel energy storage systems for wind power applications

Abstract: Wind power is generation is characterized by large extents of fluctuations in power quality and frequency stability due to the randomness and intermittence of wind speed and

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · In [72], a fuzzy, PD-based frequency regulation control strategy for wind-power and FESS system proposed to enhance the frequency regulation capability of direct-drive

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

A comprehensive review of Flywheel Energy Storage System

Jan 1, 2017 · Energy storage systems (ESSs) play a very important role in recent years. Flywheel is one of the oldest storage energy devices and it has several benefits. Flywheel Energy

Flywheel energy storage intelligent manufacturing

Flywheel energy storage intelligent manufacturing Scientific Journal of Intelligent Systems Research Volume 4 Issue 8, 2022 ISSN: 2664-9640 378 Research on frequency modulation

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy sto

Overview of Flywheel Systems for Renewable Energy

Jul 12, 2024 · wind power. The intermittent nature of these resources may introduce issues with system stability, reliability and power quality. Storing power from these intermittent sources

Overview of energy storage systems for wind power integration

Jan 1, 2021 · Several energy storage systems are available for wind energy applications such as batteries, magnetic energy storage systems, superconductors, supercapacitors, flywheel, and

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage. Fly wheels store energy in mechanical rotational

Flywheel energy storage system controlled using tube-based

Mar 1, 2025 · This paper introduces an approach for wind power smoothing using a flywheel energy storage system (FESS) controlled by a novel tube-based deep Koopman model

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

Optimization for Wind Power Integration with Flywheel Energy Storage

Aug 24, 2024 · To address the issue of highly intermittent power output from wind energy conversion systems (WECS), a strategy involving backup generators and/or energy storag

Flywheel energy storage system controlled using tube-based

Mar 1, 2025 · In this paper a novel tube-based deep Koopman MPC is employed for a flywheel energy storage system as a solution for mitigating fluctuations in wind power generation.

A comprehensive review of Flywheel Energy Storage System

Jan 1, 2017 · A comprehensive review of FESS for hybrid vehicle, railway, wind power system, hybrid power generation system, power network, marine, space and other applications are

Design of a flywheel energy storage system for

Sep 18, 2015 · Flywheel energy storage system (FESS) will be needed at different locations in the wind farm, which can suppress the wind power fluctuation and

Control strategy to smooth wind power output using battery energy

Mar 1, 2021 · In recent years, wind energy has increased its participation in the world energy mix. Besides its advantages, wind energy is not constant and presents undesired fluctuations,

Flywheel energy storage technologies for wind energy systems

Jan 1, 2010 · Applications of flywheels requiring continuous cycling at high power are discussed, including the application to smoothing wind power fluctuations in autonomous power systems

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · In this paper, state-of-the-art and future opportunities for flywheel energy storage systems are reviewed. The FESS technology is an interdisciplinary, complex subject that

A review of control strategies for flywheel energy storage

Nov 1, 2022 · The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

A comprehensive review of wind power integration and energy storage

May 15, 2024 · Integrating wind power with energy storage technologies is crucial for frequency regulation in modern power systems, ensuring the reliable and cost-effective operation of

State switch control of magnetically suspended flywheel energy storage

Jan 27, 2025 · The magnetically suspended flywheel energy storage system (MS-FESS) is an energy storage equipment that accomplishes the bidirectional transfer between electric energy

6 FAQs about [Flywheel energy storage application in wind power generation]

Are flywheel energy storage systems environmentally friendly?

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage and release, high power density, and long-term lifespan. These attributes make FESS suitable for integration into power systems in a wide range of applications.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

What is a flywheel system?

Flywheel systems are quick acting energy storage that enable smoothing of a wind turbine output to ensure a controllable power dispatch. The effectiveness of a flywheel depends on how well it can be controlled to respond to fluctuating power output from intermittent sources.

What is a flywheel energy storage system (fess)?

Flywheel energy storage systems (FESSs) satisfy the above constraints and allow frequent cycling of power without much retardation in its life span [1 - 3].

How do fly wheels store energy?

Fly wheels store energy in mechanical rotational energy to be then converted into the required power form when required. Energy storage is a vital component of any power system, as the stored energy can be used to offset inconsistencies in the power delivery system.

Are flywheels a good choice for wind farms?

There are already some applications of high-power and low- energy flywheel systems for smoothing wind power fluctuations in weak networks, and new requirements are emerging for stability improvement and protection of wind farms against network voltage dips. These applications are ideally suited to the high-power cycling capabilities of flywheels.

Learn More

- Energy storage in wind and solar power generation

- What energy storage is used for wind power generation

- Wind solar diesel and energy storage integrated power generation

- East Africa wind and solar energy storage power generation

- Guatemala communication base station flywheel energy storage photovoltaic power generation capacity

- Application scenarios of energy storage conversion on the power generation side

- Does 5 MW wind power generation require energy storage

- Wind and solar energy storage power generation

- Energy storage combined with wind power generation

Industrial & Commercial Energy Storage Market Growth

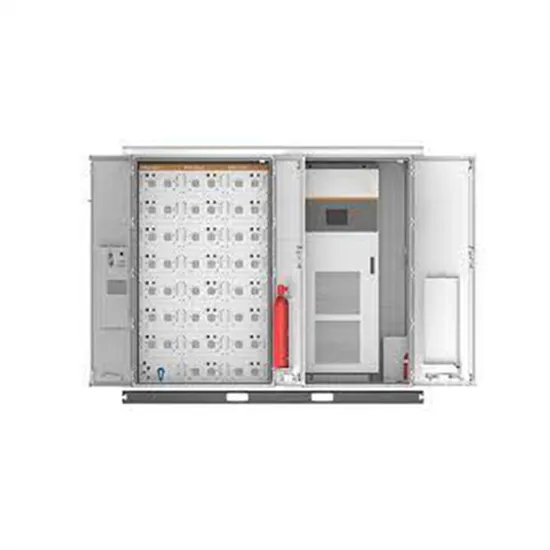

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

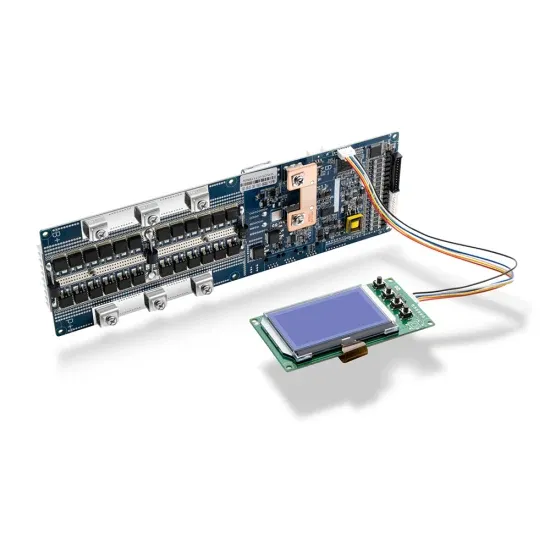

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.