Technology: Flow Battery

Nov 4, 2024 · A flow battery is an electrochemical battery, which uses liquid electrolytes stored in two tanks as its active energy storage component. For charging and discharging, these are

Modification and application of spiral flow fields in

Sep 1, 2023 · A suitable flow field structure could improve the mass transfer inside vanadium redox flow batteries (VRFB). However, previous flow fields based on th

Redox flow batteries and their stack-scale flow fields

Nov 1, 2023 · The review then investigates the pattern design and structure optimization of serpentine- and interdigitated-based flow fields before discussing challenges and strategies for

Liquid Flow Batteries: Principles, Applications, and Future

Jun 16, 2024 · Fluid flow battery is an energy storage technology with high scalability and potential for integration with renewable energy. We will delve into its working principle, main types,

Redox flow battery:Flow field design based on bionic

Oct 15, 2024 · All-vanadium redox flow batteries (VRFBs) are pivotal for achieving large-scale, long-term energy storage. A critical factor in the overall performance of VRFBs is the design of

A high-performance flow-field structured iron-chromium redox flow battery

Aug 30, 2016 · Unlike conventional iron-chromium redox flow batteries (ICRFBs) with a flow-through cell structure, in this work a high-performance ICRFB featuring a flow-field cell

Machine learning-assisted design of flow fields

May 26, 2022 · Experimental validation shows that the battery with the flow fields designed with this approach yields higher electrolyte utilization and exhibits

Modeling of vanadium redox flow battery and electrode optimization with

Jan 1, 2021 · The fibrous electrode is an essential component of the redox flow batteries, as the electrode structure influences the reactant/product local concentration, electrochemical

Progress and Perspectives of Flow Battery Technologies

Jan 18, 2019 · 摘要: Flow batteries have received increasing attention because of their ability to accelerate the utilization of renewable energy by resolving issues of discontinuity, instability

Effective splitting of serpentine flow field for applications in

Mar 1, 2021 · Redox flow batteries, and vanadium redox flow batteries (VRFB) in particular, are seen as potential solutions for grid-level storage applications due to their long life, scalability

Rechargeable redox flow batteries: Flow fields, stacks

et al. [224,231] filed patents for interleaved and interdigitated flow fields, which allow electrolyte flow to be forced through the electrode and into adjacent flow channels.

Flow Battery Technology for Power Grid Applications: A

Apr 23, 2025 · To this end, this paper provides a consolidated overview of flow battery operation, key characteristics, and advantages in grid applications. Additionally, it compares flow

Progress and Perspectives of Flow Battery

Jul 11, 2019 · Abstract Flow batteries have received increasing attention because of their ability to accelerate the utilization of renewable energy by resolving

Review of vanadium redox flow battery technology

Vanadium redox flow battery (VRFB) has a brilliant future in the field of large energy storage system (EES) due to its characteristics including fast response speed, large energy

Flow field design and performance analysis of vanadium redox flow battery

Sep 12, 2021 · Vanadium redox flow batteries (VRFBs) are one of the emerging energy storage techniques that have been developed with the purpose of effectively storing renewable energy.

Effect of flow field on the performance of an all-vanadium redox flow

Mar 1, 2016 · A comparative study of the electrochemical energy conversion performance of a single-cell all-vanadium redox flow battery (VRFB) fitted with three flow fields has been carried

Progress and Perspectives of Flow Batteries: Material Design

Feb 28, 2025 · In this chapter, we summarize the state-of-art progress on the key components of FBs, including electrolytes (from classic inorganic to organic active materials), membranes,

Flow field structure design for redox flow battery:

Aug 1, 2024 · Flow field is an important component for redox flow battery (RFB), which plays a great role in electrolyte flow and species distribution in porous ele

Advances in the design and fabrication of high-performance flow battery

May 26, 2021 · Finally, the scientific challenges and prospects of electrospun carbon fiber electrodes with maximized specific surface areas and hydraulic permeability are presented.

Flow Batteries | Wiley Online Books

Jan 9, 2023 · Flow Batteries The premier reference on flow battery technology for large-scale, high-performance, and sustainable energy storage From basics to commercial applications,

Numerical Simulation of Flow Field Structure of

Jun 6, 2024 · Furthermore, the pump-based efficiency with tapered hierarchical interdigitated flow field increased by 1.6%-3% compared with the hierarchical

Characterization and scale-up of serpentine and interdigitated flow

Sep 15, 2022 · Indeed, although having numerous beneficial characteristics in the design and operation of vanadium redox flow batteries, their low power density is hindering their

Effective splitting of serpentine flow field for applications in

Mar 1, 2021 · Request PDF | Effective splitting of serpentine flow field for applications in large-scale flow batteries | Industrial flow battery stacks require large area cells for which flow fields

6 FAQs about [Field Application of Flow Batteries]

What is flow field design for redox flow battery (RFB)?

Prospects of flow field design for RFB have been exhibited. Flow field is an important component for redox flow battery (RFB), which plays a great role in electrolyte flow and species distribution in porous electrode to enhance the mass transport. Besides, flow field structure also has a great influence in pressure drop of the battery.

What are flow field designs used in flow batteries?

Flow field designs used in flow batteries have interested many researchers and engineers since 2012. Zawodzinski’s group first reported a vanadium flow battery (VRB) with a membrane (PEM) fuel cells. Improved limiting current density and peak power density (multiple fields where electrolyte enters a long channel packed with a porous electrode.

What is a flow battery?

A corrugated electrode and this design leads to higher limiting current density and peak power density. by 3D printing. In this innovative approach, the flow battery supplies power but its fluid also carries waste heat from the electronic devices, i.e. microprocessors. For such a flow battery with

Which flow field leads to better battery performance?

It is difficult to determine which type of flow field, either serpentine or interdigitated, leads to better battery performance due to their distinct features in pressure drop and electrolyte distribution. The comparative conclusion may vary depending on the operating and assembling conditions.

How to develop advanced flow batteries for largebscale energy storage applications?

energy for largeBscale energy storage applications. To develop advanced flow batteries and needed. Several main aspects to focus are in the near term include: “dead zones” and increase the utilization of reactants. Achieving uniform flow distributions of electrolyte is especially important for the largeBscale flow battery stack designs.

Can flow batteries be used for energy storage?

energy storage applications. Flow batteries could play a significant role in maintaining the stability of the electrical grid in conjunction with intermittent renewable energy. However, they are significantly different from conventional batteries in operating principle. Recent membrane, cell design, etc.

Learn More

- Resistivity of carbon felt for flow batteries

- Application for lead-acid batteries for communication base stations

- Realize the full field application of new energy storage

- What are the main features of flow batteries

- Lebanon s vanadium reserves for all-vanadium liquid flow batteries

- How many liquid flow batteries are there in China s communication base stations

- Flow batteries need to flow

- Application of graphite electrodes in energy storage batteries

- The application of batteries in energy storage power stations

Industrial & Commercial Energy Storage Market Growth

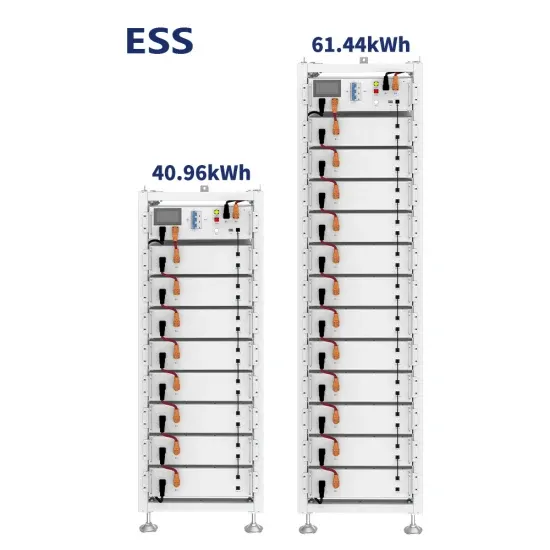

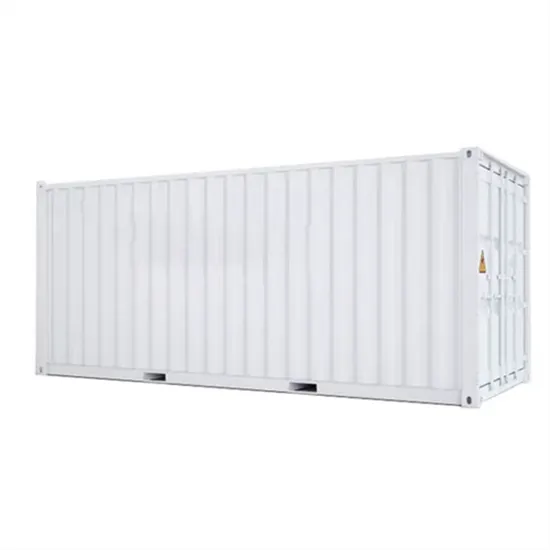

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.