Vanadium batteries

Jan 1, 2021 · The liquid with active substances is continuously circulated. The active material of vanadium liquid flow batteries is stored in liquid form in the external storage tank. The flow of

Vanadium Liquid Flow Energy Storage: The Future of Grid-Scale Battery

Why Vanadium Flow Batteries Are Stealing the Energy Storage Spotlight Ever heard of a battery that can power entire neighborhoods for 10+ hours without breaking a sweat? Meet the

Vanadium Battery | Energy Storage Sub-Segment – Flow Battery

Jun 30, 2025 · All-vanadium flow battery, full name is all-vanadium redox battery (VRB), also known as vanadium battery, is a type of flow battery, a liquid redox renewable battery with

A comprehensive review of advancements in vanadium

Vanadium Redox Flow Batteries (VRFBs) have broad application prospects in the field of electrochemical energy storage due to their long cycle life, intrinsic safety and free scalability.

Iron-vanadium redox flow batteries electrolytes: performance

Nov 10, 2024 · Performance comparison of all-vanadium and DES electrolytes in vanadium redox flow batteries. (a)Full-cell test platform; (b) Coulombic and voltage efficiencies over 20 cycles;

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · Disadvantages are also very obvious, vanadium battery energy density is low, can only reach 40Wh/kg, with a lithium-ion battery difference of more than ten times; vanadium

Review—Preparation and modification of all-vanadium redox flow battery

Nov 21, 2024 · As a large-scale energy storage battery, the all-vanadium redox flow battery (VRFB) holds great significance for green energy storage. The electrolyte, a crucial

Investigation of modified deep eutectic solvent for high

Dec 20, 2024 · The introduction of the vanadium redox flow battery (VRFB) in the mid-1980s by Maria Kazacoz and colleagues [1] represented a significant breakthrough in the realm of redox

Review—Preparation and modification of all‐vanadium

Feb 15, 2025 · Abstract As a large-scale energy storage battery, the all-vanadium redox flow battery (VRFB) holds great significance for green energy storage. The electrolyte, a crucial

lebanon electric all-vanadium liquid flow battery energy

Huo et al. demonstrate a vanadium-chromium redox flow battery that combines the merits of all-vanadium and iron-chromium redox flow batteries. The developed system with high theoretical

Global electrolyte standard ''crucial for scalability

Mar 11, 2025 · Global standards and specifications for the electrolyte used in vanadium redox flow batteries are "crucial" for the technology''s prospects.

all-vanadium liquid flow energy storage battery lebanon

Here''s some videos on about all-vanadium liquid flow energy storage battery lebanon electric SCHMID Energy Systems: Basics of a Vanadium Redox Flow SCHMID Energy

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · In 1976. research scholars found that vanadium can be used as the active substance of the liquid current battery; in 1958. scholars theoretically proved the feasibility of

VANADIUM ENERGY STORAGE LEBANON ELECTRIC

Liquid metal battery, flow battery and liquid air storage technology are among the very few potentially mobile electrical energy storage technologies capable of achieving such levels of

Electrode materials for vanadium redox flow batteries:

Jan 1, 2022 · The design and future development of vanadium redox flow battery were prospected. Vanadium redox flow battery (VRFB) is considered to be one of the most

Bushveld Energy Company and the Vanadium Redox

Mar 10, 2020 · How does a vanadium redox flow battery (VRFB) work? A flow battery was first developed by NASA in the 1970s and is charged and discharged by a reversible reduction

Vanadium Redox Flow Batteries

Jul 30, 2023 · Vanadium Redox Flow Batteries: Technology Considerations Flow batteries are generally defined as batteries that transform the electron flow from activated electrolyte into

Performance enhancement of vanadium redox flow battery

Oct 10, 2024 · This study investigates a novel curvature streamlined design, drawing inspiration from natural forms, aiming to enhance the performance of vanadium redox flow battery cells

lebanon electric vanadium liquid flow energy storage

Huo et al. demonstrate a vanadium-chromium redox flow battery that combines the merits of all-vanadium and iron-chromium redox flow batteries. The developed system with high theoretical

Prospects for industrial vanadium flow batteries

Jul 15, 2023 · Open access Abstract Vanadium Flow Batteries (VFBs) are a stationary energy storage technology, that can play a pivotal role in the integration of renewable sources into the

All-vanadium redox flow batteries

Jan 1, 2025 · The most commercially developed chemistry for redox flow batteries is the all-vanadium system, which has the advantage of reduced effects of species crossover as it

Novel electrolyte design for high-efficiency vanadium redox flow

Jul 15, 2025 · Abstract Vanadium redox flow batteries (VRFB) are gradually becoming an important support to address the serious limitations of renewable energy development. The

Lebanon All-vanadium Liquid Flow Battery

Vanadium/air single-flow battery is a new battery concept developed on the basis of all-vanadium flow battery and fuel cell technology [10]. The battery uses the negative electrode system of

Novel electrolyte design for high-efficiency vanadium redox flow

Jul 15, 2025 · Novel V-Cl co-sourced electrolyte achieves 3.0 M vanadium concentration with −5 ℃–50 ℃ stability. Cl - -SO 42− synergistic coordination inhibits V 3+ deprotonation and

The 10MW/40MW All-Vanadium Liquid Flow Battery Energy

Apr 1, 2021 · The energy storage scale of all-vanadium liquid flow battery is 10MW/40MWh respectively. Dalian Rongke Energy Storage Technology Development Co., Ltd. is a high-tech

A Review of Capacity Decay Studies of All‐vanadium

Aug 13, 2024 · This review generally overview the problems related to the capacity attenuation of all-vanadium flow batteries, which is of great significance for understanding the mechanism

Membranes for all vanadium redox flow batteries

Dec 1, 2020 · Exposure of the polymeric membrane to the highly oxidative and acidic environment of the vanadium electrolyte can result in membrane deterioration. Furthermore, poor

6 FAQs about [Lebanon s vanadium reserves for all-vanadium liquid flow batteries]

When can a vanadium battery be used?

The Vanadium is usable at the end of the lifespan of the battery. “VRFB along with lead acid is the only battery chemistry to receive a letter of no objection from the New York Fire Department.” Source: “Energy Storage System Safety: Vanadium Redox Flow Vs.

Why are vanadium redox flow battery systems important?

Battery storage systems become increasingly more important to fulfil large demands in peaks of energy consumption due to the increasing supply of intermittent renewable energy. The vanadium redox flow battery systems are attracting attention because of scalability and robustness of these systems make them highly promising.

Can ion transport improve vanadium redox flow battery electrolytes?

Furthermore, research progress in other battery fields shows that optimizing electrolyte formulations [21, 22] and ion transport [23, 24] can significantly enhance energy density and cycling stability, providing valuable insights for improving vanadium redox flow battery electrolytes. Table 1.

Why does a vanadium electrolyte deteriorate a battery membrane?

Exposure of the polymeric membrane to the highly oxidative and acidic environment of the vanadium electrolyte can result in membrane deterioration. Furthermore, poor membrane selectivity towards vanadium permeability can lead to faster discharge times of the battery. These areas seek room for improvement to increase battery lifetime.

What is a single vanadium element battery?

Their single vanadium element system avoids capacity fading caused by crossover contamination in iron-chromium flow batteries (ICFBs) . Additionally, VRFBs use an aqueous electrolyte, eliminating the safety risks associated with bromine vapor corrosion in zinc-bromine flow batteries (ZBFBs) .

What are vanadium redox flow batteries (VRFB)?

Vanadium redox flow batteries (VRFB) are gradually becoming an important support to address the serious limitations of renewable energy development. The ideal electrolyte for vanadium batteries needs to ensure the stability of high-concentration vanadium ions in different oxidation states over a wide temperature range.

Learn More

- Which companies produce vanadium liquid flow batteries

- How many liquid flow batteries are there in China s communication base stations

- How to avoid liquid flow batteries in communication base stations

- Do long-lasting liquid flow batteries work

- All-vanadium liquid flow battery rate

- New all-vanadium liquid flow energy storage pump

- Ouagadougou all-vanadium liquid flow battery

- 30kw all-vanadium liquid flow energy storage battery

- Sukhumi All-vanadium Liquid Flow Battery

Industrial & Commercial Energy Storage Market Growth

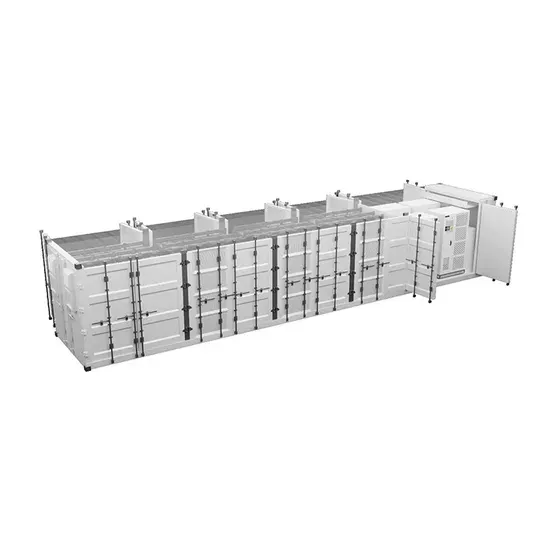

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.