A promising assembled electrode-bipolar plate for redox flow battery

Sep 10, 2024 · For example, some technologists applied an assembled electrode-bipolar plate (AEBP) in a vanadium redox flow battery [12] to obtain lower resistivity and higher energy

Electric and Hydraulic Properties of Carbon Felt Immersed in

Abstract Electroconductive carbon felt (CF) material, having a permeable structure and significant electroconductive surface, is widely used for electrodes in numerous electrochemical

(PDF) Electric and Hydraulic Properties of Carbon Felt

Apr 23, 2018 · Electroconductive carbon felt (CF) material, having a permeable structure and significant electroconductive surface, is widely used for electrodes in numerous

Performance evaluation of thermally treated graphite felt electrodes

Mar 15, 2018 · In our contribution we study the electrocatalytic effect of oxygen functionalization of thermally treated graphite felt on kinetics of electrode reactions of vanadium redox flow

Regulating flow field design on carbon felt electrode

Dec 15, 2022 · Finally, dynamic modelling and simulation of an industrial-scale 32 kW stack highlight a desirable system efficiency of ca. 70 % for the parallel flow felt design at 200 mA

Question: SGL Carbon SIGRACELL

Sep 8, 2020 · Question: SGL Carbon SIGRACELL® graphite felts are provided as the electrode material for Scribner''s Redox Flow Battery (RFB) cell fixture kit. Scribner offers two

Research of Nanostructured Carbon Felt Materials as

Sep 10, 2021 · Therefore, in this research the modification method of felt electrodes to reduce the resistivity of a flow battery cell. The modification is carried out by thermal catalytic

Characterization of Carbon Felt Electrodes for Vanadium

Feb 9, 2019 · For carbonized felts, thermal treatment highly reduced the electrochemical activity characterized by cyclic voltammetry due to a reduced overall oxygen content and increased

Non-woven pitch-based carbon fiber electrodes for low-cost redox flow

Compared to commercial PAN-derived carbon fiber felt, pitch-based NWCFs have increased graphitic content, tensile strength, and electrical conductivity at a fraction of the cost. RFBs

Soft Graphite Battery Felt – A Efficient Energy Storage Solution

May 24, 2025 · Soft graphite battery felt, as a premium electrode material for most energy storage systems, like vanadium redox flow batteries, utilizes special fibers and weaving techniques,

Theoretical Description of Carbon Felt Electrical Properties

Electro-conductive carbon felt (CF) material is composed by bonding together different lengths of carbon filaments resulting in a porous structure with a significant internal surface that facilitates

COMPREHENSIVE ANALYSIS OF CARBON FELT

Sep 2, 2018 · Carbon felt material is widely used for electrodes substances in different applications including electrochemical [1-7]. For today its most prominent utilization is in the

Short thermal treatment of carbon felts for copper

For this reason, the effect and duration of thermal treatment of the carbon felt on the performance of the copper-based RFB has to be determined. Both poly-acrylonitrile and rayon carbon felts

Boosting performance of Ti3C2TX/Bi modified graphite felt

Jan 1, 2024 · Effect of oxygen plasma treatment on the electrochemical performance of the rayon and polyacrylonitrile based carbon felt for the vanadium redox flow battery application

How to design carbon felt/graphite felt to reduce the

Aug 19, 2025 · The most promising carbon electrodes in all vanadium flow batteries currently include carbon felt (CF), graphite felt (GF), and carbon paper (CP), which have received

Characterization of Carbon Felt Electrodes for Vanadium

Feb 9, 2019 · By nature, many renewable energy sources like wind and solar power plants have a fluctuating energy output. Redox flow batteries (RFBs) are a promising technology to

Compressed composite carbon felt as a negative electrode

Dec 7, 2022 · Due to the corrosive nature of zinc–iron battery''s electrolyte, carbon-based materials are generally implemented. Among them, carbon felt (CF) stands out due to its good

6 FAQs about [Resistivity of carbon felt for flow batteries]

Can felt electrodes reduce the resistivity of a flow battery cell?

Therefore, in this research the modification method of felt electrodes to reduce the resistivity of a flow battery cell. The modification is carried out by thermal catalytic decomposition of propane/butane on the surface of a carbon fiber.

Can carbon felt electrodes be used in redox flow batteries?

6. Conclusions In this study, a commercially available carbon felt electrode designed for use in redox flow batteries by SGL has been investigated for the impact of compression on the electrical resistivity, and the single-phase and multi-phase fluid flow.

Are carbon felt electrodes a good choice for large-scale energy storage?

They are considered an excellent choice for large-scale energy storage. Carbon felt (CF) electrodes are commonly used as porous electrodes in flow batteries. In vanadium flow batteries, both active materials and discharge products are in a liquid phase, thus leaving no trace on the electrode surface.

What is the electrical resistivity of carbon felt?

Gonzales-Garcia et al. also presented their measurements of electrical resistivity of carbon felt materials, which was in the range of 10–16.3 mΩ m. In comparison, the results presented in this work, demonstrate the electrical resistivity of GFA6 ranges between 8–10 mΩ m and changes as a function of compression.

What is a carbon felt electrode?

A critical component of the RFBs is the carbon felt electrodes which provide the surface area for the reaction to occur. The structure of these electrodes is crucial to the operation as it defines the ease of flow of the electrolyte through the electrode, electrical conductivity, and structural stability .

Are flow batteries a good choice for large-scale energy storage?

Flow batteries possess several attractive features including long cycle life, flexible design, ease of scaling up, and high safety. They are considered an excellent choice for large-scale energy storage. Carbon felt (CF) electrodes are commonly used as porous electrodes in flow batteries.

Learn More

- Carbon Felt Thickness for Flow Battery

- Mass production of zinc-based flow batteries

- Special Applications of Flow Batteries

- Advantages of nickel-bromine flow batteries

- Which companies produce vanadium liquid flow batteries

- Do long-lasting liquid flow batteries work

- When will flow batteries be used

- Communication base station flow battery tower has batteries

- Syria s new generation of communication base station flow batteries

Industrial & Commercial Energy Storage Market Growth

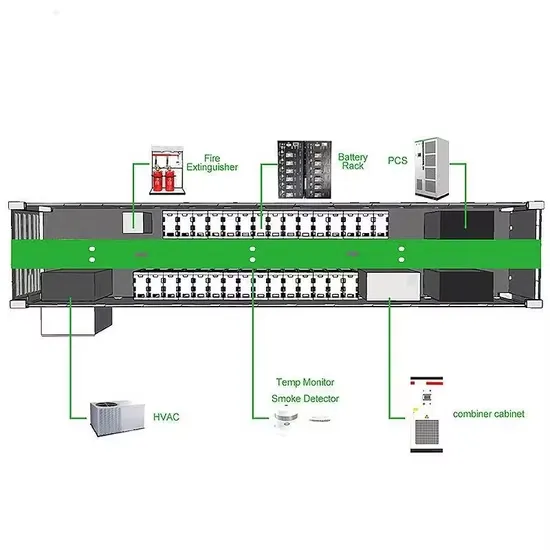

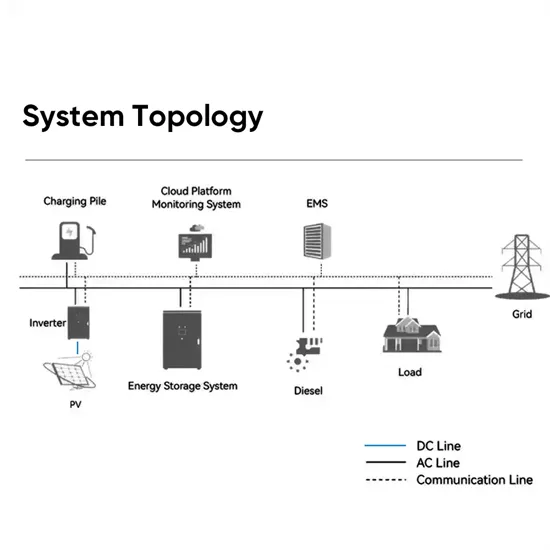

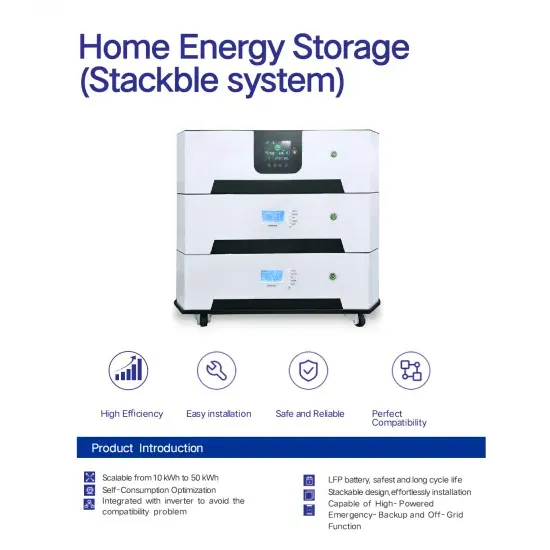

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.