Highly transparent anti-reflection coating enhances the

Aug 22, 2024 · From the results of Figs. 1(d) and 1(e), it is also evident that HFDA is highly transparent, and anti-reflective, thereby improving the light absorption of perovskite solar cells

Highly transparent anti-reflection coating enhances the

Here, a remarkable conversion efficiency of 14.7% was achieved underwater after encapsulating the solar modules with 1H,1H,2H,2H-heptadecafluorodecyl acrylate (HFDA) coatings, which is

Highly transparent anti-reflection coating

Jul 11, 2024 · This highly transparent ARC shows great potentials in enhancing the stability of perovskite devices, applicable not only to underwater cells but

Highly transparent, superhydrophobic, and durable

Jul 20, 2024 · In this study, a simple dip-coating process was used to prepare a highly transparent superhydrophobic self-cleaning coating, with a bilayer structure consisting of a

High Efficiency Anti-Reflective Coating for PV Module Glass

Jun 30, 2017 · Abstract: Without antireflective coating, more than 4% of incident light is reflected from the standard front cover glass of photovoltaic (PV) modules. Module efficiency is one of

Synthesis and Characterization of Highly Transparent Sol-Gel Glass

Jan 1, 2009 · Room temperature sol-gel synthesis and optical characterization of highly transparent silica glass for photovoltaic (PV) applications is presented in this paper.

Highly Water-Repellent and Anti-Reflective Glass

Jul 7, 2022 · Abstract and Figures Optically anti-reflective and water-repellent glass is required for solar cell covers to improve power-generation efficiency

Simple synthesis of weather-resistant and self-cleaning anti-reflective

Dec 1, 2024 · In contemporary optical applications, discrepancies in refractive indices at the interfaces of transparent substrates often induce light reflection, leading to a gamut of

Highly reliable anti-reflection radiative cooling glass

Oct 15, 2024 · Herein, an anti-reflection radiative cooling (ARRC) glass for photovoltaic (PV) devices is proposed by multi-layer design. Harnessing the synergy of anti-reflection layers and

Durable superhydrophilic and antireflective coating for high

Jan 28, 2021 · Antireflection coatings have received extensive attention due to their unique ability to reduce the reflection losses of incident light in photovoltaic (PV) systems. In this study, we

Improving the light transmission of silica glass using silicone

Sep 15, 2024 · The anti-reflection (AR) technology currently used in photovoltaic (PV) glass has reached its operational limit as the refractive index of existing materials cannot be lowered

Highly transparent anti-reflection coating enhances the

Furthermore, being exposed to air, the encapsulated PSMs maintained 94% of their original efficiency after 1000 h light illumination. This highly transparent ARC shows great potentials in

Development of anti-reflective coatings with photocatalytic

May 15, 2025 · Advanced PV glass substrates engineered with high optical transparency (>92 % at 550 nm) and broadband solar transmittance (300–1200 nm) have been implemented to

High Efficiency Anti-Reflective Coating for PV Module Glass

Jun 30, 2017 · Without antireflective coating, more than 4% of incident light is reflected from the standard front cover glass of photovoltaic (PV) modules. Module efficiency is one of the largest

Refractive film for photovoltaic panels

One promising approach involves the application of antireflective coatings to the surface of the photovoltaic glass to improve its transmittance. However,balancing mechanical durability,self

AN ANALYSIS OF ANTI-PID TECHNOLOGIES IN SOLAR

Apr 8, 2023 · ABSTRACT This study provides a comprehensive analysis of Anti-PID (Potential Induced Degradation) technologies in solar panels. PID is a phenomenon that can occur in

Non-fluorinated superhydrophobic film with high transparency

Jan 30, 2023 · The dust deposition layers also increase heat transfer resistance and impact heat dissipation, potentially leading to PV modules burnout in extreme conditions. To eliminate the

Highly solar transparent and low-emissivity glass based on

Feb 1, 2025 · Moreover, the visible transmittance of IHO can be further improved by incorporating anti-reflection coatings with carefully selected refractive indices and thicknesses [35]. MgF 2

Antireflective, photocatalytic, and superhydrophilic coating

Jan 31, 2022 · Although solar photovoltaic panel cover glass is highly transparent, it has a natural reflectance in the visible wavelength range. An effective method to increase the effectiveness

Mechanically robust and self-cleaning antireflective coatings

Sep 15, 2024 · As the conversion efficiency of solar cells approaches its theoretical upper limit, the importance of photon management in enhancing photovoltaic modules performance

6 FAQs about [Highly reflective highly transparent and anti-PID photovoltaic glass]

Does solar photovoltaic panel cover glass have a natural reflectance?

Although solar photovoltaic panel cover glass is highly transparent, it has a natural reflectance in the visible wavelength range. An effective method to increase the effectiveness is to reduce the optical loss and natural reflectance via antireflection (AR) coatings.

Does antireflective coating improve solar module efficiency?

Abstract: Without antireflective coating, more than 4% of incident light is reflected from the standard front cover glass of photovoltaic (PV) modules. Module efficiency is one of the largest levers to impact the cost-per-watt of solar and recovering some of this reflected light with a simple anti-reflective coating (ARC) has become widespread.

Are solar panels antireflective and photocatalytic?

In this work, commercial solar panels were coated with sparked titanium films, and the antireflective, super-hydrophilic, and photocatalytic properties of the films were investigated. The reflectance, photocatalytic properties, and degradation of the organic pollutant methylene blue were determined using UV–Vis spectroscopy.

Are PV solar glass coatings reliable?

Furthermore, the coating showed great resistance to high temperature and high humidity as well as high stability to long-time outdoor exposure. The results suggest the good reliability of the prepared coatings for PV solar glass application.

What are the advantages of PV glass substrates?

Advanced PV glass substrates engineered with high optical transparency (>92 % at 550 nm) and broadband solar transmittance (300–1200 nm) have been implemented to maximize power conversion efficiency (PCE) while providing robust protection against environmental degradation .

What are optical materials exhibiting high Antireflective properties?

Optical materials exhibiting high antireflective properties have attracted great interest owing to their wide range of applications in solar photovoltaic (PV) cells, mirrors, glasses, photodetectors, etc. (Guo et al. 2013; Kim et al. 2017; Wan et al. 2017; Dong et al. 2018; Zhang et al. 2019a).

Learn More

- Comoros Transparent Series Photovoltaic Glass Cadmium Telluride

- Photovoltaic glass is fully transparent

- Solar photovoltaic transparent glass

- Photovoltaic power generation transparent glass

- Environmental protection requirements for photovoltaic glass

- The difference between ito conductive glass and photovoltaic glass

- Photovoltaic panels like glass

- Maputo Photovoltaic Conductive Glass

- Photovoltaic AR anti-reflective glass

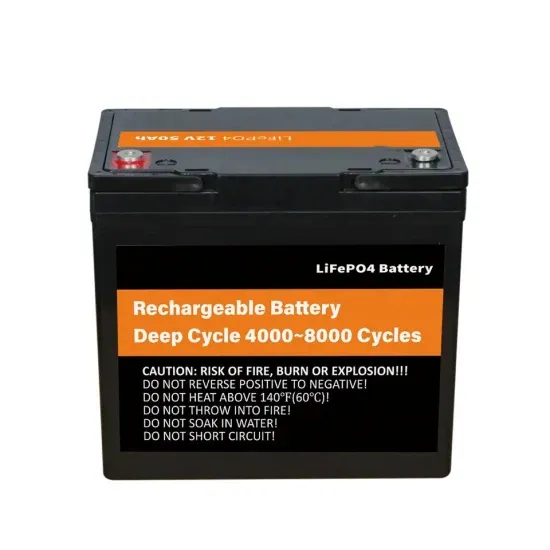

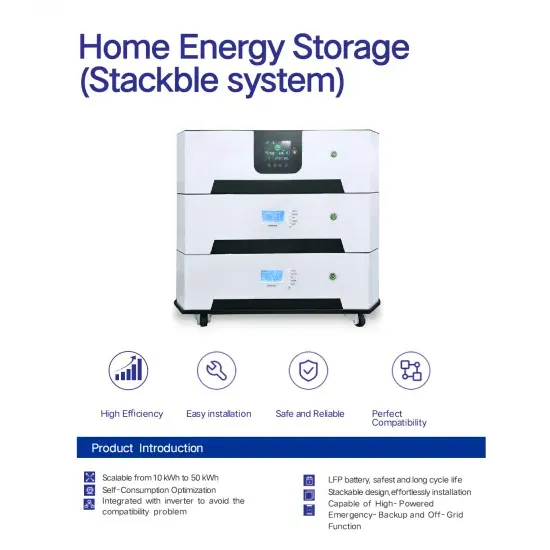

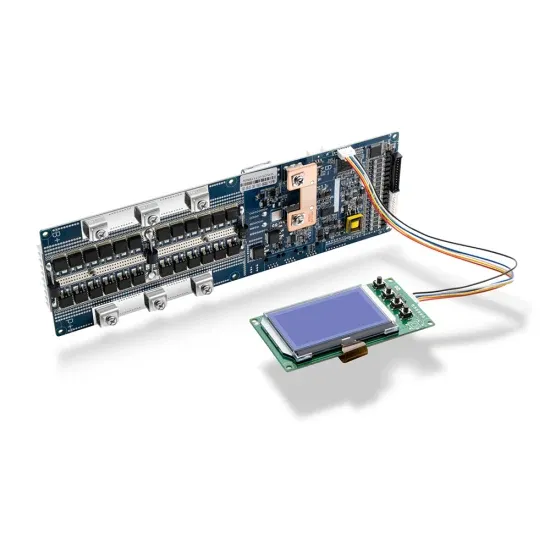

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.