Brief review of cadmium telluride-based photovoltaic

Jun 27, 2014 · Implementation of better quality glass, more transparent conductive oxides, introduction of a high-resistivity transparent film under the CdS junction-partner, higher

Cadmium Telluride Solar Cells: From Fundamental Science to

In order to meet aggressive decarbonization goals, photovoltacs (PV) need to expand substantially. The current technology that heavily dominates the market, silicon (Si), comprises

UK researchers developing new type of cadmium telluride PV

Jul 4, 2025 · A team of UK researchers is working on lightweight cadmium telluride (CdTe) solar devices for space arrays. The aim is to develop 20%-efficient ultra-thin devices to provide

Cadmium Telluride Power Generation Glass Market

Feb 28, 2025 · Impact of Regional Regulatory Frameworks on CdTe Photovoltaic Glass Commercialization Regional regulatory frameworks create divergent pathways for Cadmium

Comparative study of cadmium telluride solar cell

Jul 23, 2024 · Schematic of cadmium telluride (CdTe) device structure on (A) fluorine-doped tin oxide (FTO)-coated soda-lime glass substrate, (B) aluminium-doped zinc oxide (AZO)/ZnO

Translucent photovoltaic glass: the "sun magic master" that

Driven by the dual goals of "carbon neutrality" and rural revitalization, agrivoltaics is undergoing an industry upgrade from "simple superposition" to "deep coupling." In this transformation,

A comprehensive review of flexible cadmium telluride solar

Nov 1, 2023 · Recent advancements in CdTe solar cell technology have introduced the integration of flexible substrates, providing lightweight and adaptable energy solutions for various

The structure, size, and transparency selection of power

The cadmium telluride power generation glass used in photovoltaic curtain walls is limited in size due to current production processes. Considering the appearance and construction cost of

Cadmium telluride power glass: future vegetable greenhouses

With the continuous progress of science and technology, the application field of new energy materials is becoming more and more extensive. Among them, cadmium telluride power

''FAMELINE PV Glass'' — Solar Power Generating Glass for

Aug 6, 2025 · Mono Crystalline PV Glass: Designed for skylights, canopies, or parking structures, this type uses monocrystalline solar cells laminated between two layers of tempered glass. It

Cadmium Telluride Solar Cells on Ultrathin Glass for

Aug 28, 2017 · This paper details the preliminary findings of a study to achieve a durable thin-film CdTe photovoltaic (PV) device structure on ultrathin space-qualified cover glass. An aluminum

Innovative CdTe Solar Technology: Transparent

Mar 11, 2024 · The CdTe (Cadmium Telluride) solar panel is an important branch of thin-film solar technology. Some of its advantages compared to traditional c

Transparent Photovoltaic Windows

Apr 4, 2023 · Therefore, low-VLT regime absorbers would result in semitransparent PV windows in which absorber materials like silicon (Si), perovskite or cadmium telluride (CdTe) could be

Cadmium telluride (CdTe) thin film solar cells

Jan 1, 2022 · Semiconductors are the basic photovoltaic materials used in inorganic solar cells. Recently, research activities have shifted progressively toward thin film solar cells utilizing

CdTe Perspective Paper

Jan 16, 2025 · This document describes the state of cadmium telluride (CdTe) photovoltaic (PV) technology and then provides the perspective of the U.S. Department of Energy (DOE) Solar

Research on ultra-thin cadmium telluride heterojunction thin

Jan 1, 2025 · Cadmium Telluride thin film solar cell is very suitable for building integrated photovoltaics due to its high efficiency and excellent stability. To further reduce the production

Cadmium Telluride Solar Cells | Photovoltaic Research | NREL

Apr 3, 2025 · Cadmium Telluride Solar Cells The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and

Impacts of type of partial transparency on strawberry

Mar 18, 2025 · This study compares strawberry agrivoltaics using two different types of solar photovoltaic (PV) modules: uniform illumination provided from semi-transparent thin-film

China Transparent Solar Panel Cadmium Telluride Power Generation Glass

Photoelectric glass, also known as photovoltaic glass or solar glass, is a type of glass that integrates photovoltaic (PV) cells for electricity generation. These cells are typically made of

Integrated semi-transparent cadmium telluride photovoltaic

Sep 28, 2018 · When integrating photovoltaics into building windows, the photovoltaic glazing modules inhibit the function that glass performs, with the additional function of energy

Brief review of cadmium telluride-based photovoltaic

Jun 27, 2014 · Implementation of better quality glass, more transparent conductive oxides, introduction of a high-resistivity transparent film under the CdS junction-partner, higher

Cdte Photovoltaic, Cadmium Telluride Cdte Solar Panels

CdTe is one of the materials used in thin-film solar cells, and when applied to glass surfaces, it creates a transparent or semi-transparent layer that can convert sunlight into electricity. This

CdTe-based thin film photovoltaics: Recent advances,

Jun 15, 2023 · Cadmium telluride (CdTe)-based cells have emerged as the leading commercialized thin film photovoltaic technology and has intrinsically better temperature

6 FAQs about [Comoros Transparent Series Photovoltaic Glass Cadmium Telluride]

What is a CdTe (cadmium telluride) solar panel?

A CdTe (Cadmium Telluride) solar panel is an important branch of thin-film solar technology. It offers several advantages over traditional c-Si panels, leading to its growing adoption in various segments, including industrial, commercial, and residential. Currently, it represents around 5-6% of the global panel market share.

What makes CdTe a good choice for transparent solar panels?

CdTe's excellent thickness makes it a good fit for creating transparent solar panels. Experts can manufacture these panels with varying transparency percentages by applying trade-offs between thickness (transparency) and efficiency.

What are transparent solar panels?

Although it is acceptable to call them ‘transparent solar panels’, they are not authentically transparent photovoltaic glass panels. The formal term for MSU’s technology is transparent luminescent solar concentrator (TLSC). This milestone began to procure tremendous traction for the technology and spur significant strides in its development.

Are semi-transparent solar panels the 'transparent roadmap'?

Semi-transparent solar panels are indeed part of the ‘transparent roadmap’. They make some compromises on transparency to improve efficiency.

Can transparent solar panels be wired?

Transparent solar panels can be wired, as demonstrated in the image. However, improving their efficiency is challenging due to the inherent constraint of converting invisible light waves while allowing visible light waves to pass through.

Who makes TCO-coated glass?

Nippon Sheet Glass Group is the preeminent supplier of this commodity, with a large factory (inaugurated in 2020) located near both First Solar and Toledo Solar in Lucky, Ohio. Recently, Vitro Architectural Glass agreed to supply TCO-coated glass to First Solar, expanding and upgrading their Carlisle, Pennsylvania plant.14

Learn More

- Top Ten Cadmium Telluride Photovoltaic Glass

- Photovoltaic conversion efficiency of cadmium telluride glass

- Japanese light-transmitting series photovoltaic power generation glass design

- Photovoltaic glass is fully transparent

- Solar photovoltaic transparent glass

- Photovoltaic transparent glass load-bearing

- Malaysia Penang Photovoltaic Transparent Glass Manufacturer

- Highly reflective highly transparent and anti-PID photovoltaic glass

- Annual power generation of transparent glass photovoltaic

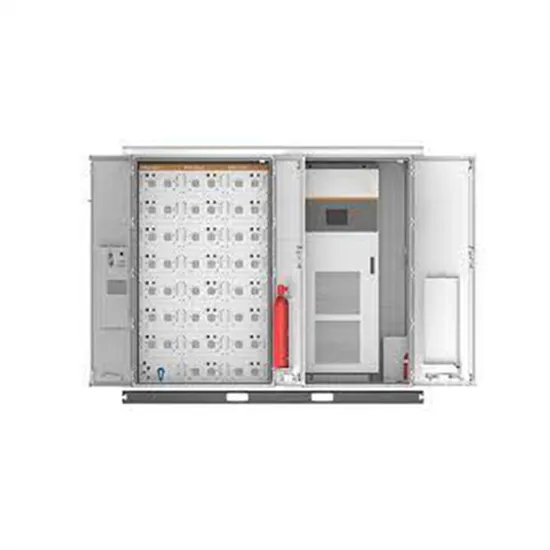

Industrial & Commercial Energy Storage Market Growth

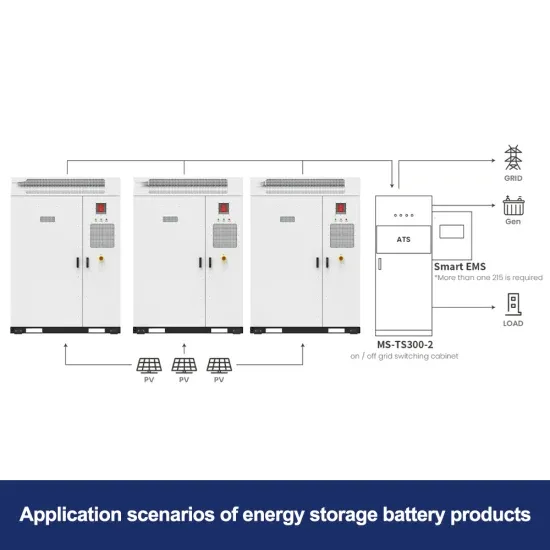

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

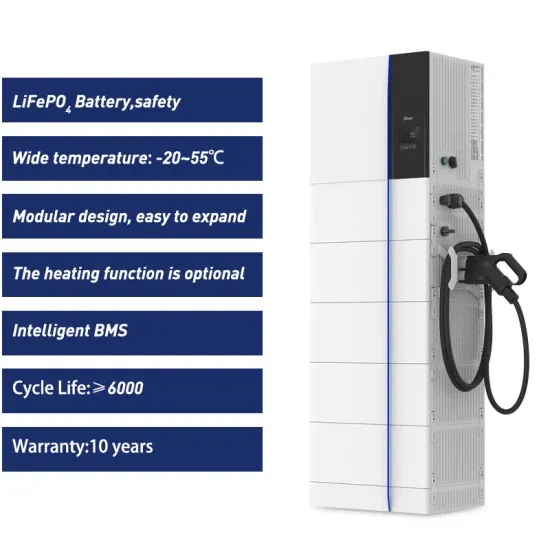

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.