BIPV benchmark project! The nation''s largest airport cadmium telluride

The T2 terminal''s BIPV photovoltaic skylight, equipped with this glass, has become the largest photovoltaic skylight project using translucent cadmium telluride photovoltaic power generation

碲化镉发电玻璃市场规模及 2032 年未来增长

Aug 24, 2024 · The major applications of Cadmium Telluride Power Generation Glass include utility-scale solar power plants, commercial and industrial solar power systems, and residential

Cadmium telluride photovoltaic glass power generation

Cadmium telluride (CdTe)-based cells have emerged as the leading commercialized thin film photovoltaic technology and has intrinsically better temperature coefficients, energy yield, and

Research on ultra-thin cadmium telluride heterojunction thin

Jan 1, 2025 · Cadmium Telluride thin film solar cell is very suitable for building integrated photovoltaics due to its high efficiency and excellent stability. To further reduce the production

UK researchers developing new type of cadmium telluride PV

Jul 4, 2025 · A team of UK researchers is working on lightweight cadmium telluride (CdTe) solar devices for space arrays. The aim is to develop 20%-efficient ultra-thin devices to provide

Cadmium telluride power glass: future vegetable greenhouses

Cadmium telluride power generation glass, as the name suggests, is a special glass that can simultaneously realize photovoltaic power generation and use as a building material. It uses

Integrated semi-transparent cadmium telluride photovoltaic glazing

Dec 1, 2018 · Assess the impact of design factors of semi-transparent PV window on building performance. Evaluate an office performance with integrated STPV window using innovate

What is Cadmium Telluride? Definition,

Jul 22, 2024 · Cadmium Telluride (CdTe) is a stable crystalline compound utilized in thin-film solar technology to convert sunlight into electricity. This material is

Cadmium Telluride Solar Cells | Photovoltaic Research | NREL

Apr 3, 2025 · Cadmium Telluride Solar Cells The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and

Comparative study of cadmium telluride solar cell

Jul 23, 2024 · CdTe solar cells were fabricated using MOCVD, according to the superstrate structure on two different glass substrates: fluorine-doped tin oxide (FTO)-coated soda-lime

Cadmium Telluride vs Silicon Solar Cells : Which Performs

Jul 10, 2025 · When you look at solar panels, silicon works better. Monocrystalline silicon panels can reach 20–27% efficiency. Cadmium Telluride (CdTe) Solar Technology has 16% to 18%

CdTe Perspective Paper

Jan 16, 2025 · This document describes the state of cadmium telluride (CdTe) photovoltaic (PV) technology and then provides the perspective of the U.S. Department of Energy (DOE) Solar

Future of cadmium telluride PV tech

May 13, 2021 · In the third interview of a series, <b>pv magazine</b> spoke to Prof. Arvind Shah of École polytechnique fédérale de Lausanne and Associate

3 FAQs about [Top Ten Cadmium Telluride Photovoltaic Glass]

Can cadmium zine Telluride and cdmgte be used together?

The incorporation of zinc or magnesium to form cadmium zine telluride (CdZnTe) and cadmium magnesium telluride (CdMgTe) represents a possible way to move the bandgap into a viable regime for tandem incorporation, but using these materials introduces processing challenges that have thus far prevented their use in high-throughput manufacturing.

Are CdTe photovoltaics better than silicon?

The streamlined manufacturing process of CdTe photovoltaics can offer certain advantages over that of silicon: an 18.5% efficient CdTe module has about 35% the embodied energy compared to a single-crystal silicon module of the same power rating (144 half-cell bifacial silicon passivated emitter and rear contact module with 21% efficiency).

How do different types of PV modules affect a glazing façade?

When integrating different types of PV modules into a building window or glazing façade, the variation of thermo-optical (e.g. emissivity, solar and visible) transmittance of the glazing material will affect the fraction of absorbed, transmitted and re-radiated solar radiation, as well as the amount of penetrating daylight.

Learn More

- Comoros Transparent Series Photovoltaic Glass Cadmium Telluride

- Photovoltaic conversion efficiency of cadmium telluride glass

- Cadmium telluride power generation glass energy storage

- Abu Dhabi non-standard photovoltaic glass component research and development

- Photovoltaic glass solar power generation

- Photovoltaic glass back frame

- How much does 2mm photovoltaic glass cost

- Installation of photovoltaic curtain wall with power generation glass

- Photovoltaic floor-to-ceiling glass

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

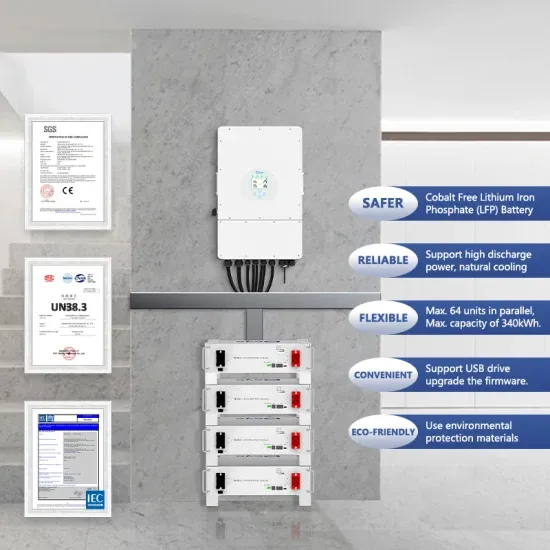

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.