Why do power batteries come in 3 shapes? Why is the market for square

Sep 25, 2021 Why do power batteries come in 3 shapes? Why is the market for square-shaped batteries performing so strongly? Why do power batteries come in 3 shapes? Why is the

What are the structure and advantages and disadvantages of square

According to the shape of the picture, lithium-ion batteries are divided into square lithium batteries (such as commonly used mobile phone battery cells), cylindrical lithium batteries (such as

Square Lithium Iron Phosphate Battery for Electric

Introduction to Square Lithium Iron Phosphate Batteries In the realm of electric vehicles, square lithium iron phosphate batteries have emerged as a significant power source. These batteries

What are the structure and advantages and disadvantages of square

There are three main packaging forms of mainstream lithium batteries, namely cylinder, square and soft package. Rectangular lithium batteries usually refer to aluminum or steel prismatic

What Are Square Batteries and Their Characteristics?

Apr 11, 2025 · Square batteries, also known as prismatic cells, are rectangular-shaped power sources with layered internal structures. Their flat design maximizes space efficiency, making

A brief introduction to square lithium batteries.

Aug 7, 2025 · Generally speaking, square lithium batteries and soft pack lithium batteries each have their own advantages and disadvantages. Each battery has its own areas of advantage.

A Guide to the 7 Main Lithium Battery Types –

Mar 21, 2025 · In this article, we will discuss in more depth the 7 types of lithium batteries are there, compare each type, and determine the best type for

Understanding the Structure of Square Lithium Batteries

Aug 24, 2024 · Square (or prismatic) lithium batteries are widely used in energy storage systems and electric vehicles due to their compact design and high energy density. Unlike cylindrical

Do You Know Why Lithium Batteries are Mostly Cylindrical and Square

Apr 23, 2025 · Whether it is a mobile phone, an electric vehicle or an energy storage power station, the shape of lithium batteries is mostly cylindrical or square. These two designs may

Why do power batteries come in 3 shapes? Why is the market for square

Sep 25, 2021 · Square-shaped batteries have the advantages of small internal resistance, long cycle life, high reliability of packaging, good resistance, relatively simple grouping, high system

Square aluminum shell lithium-ion battery energy storage

Domestic power lithium battery manufacturers often use square aluminum shell lithium batteries with higher energy density because the structure of square lithium batteries is relatively

The Ultimate Guide to Lithium Ion Battery Sizes

Jul 12, 2024 · From cylindrical batteries in laptops and electric vehicles to prismatic batteries in smartphones and tablets, there''s a lithium-ion battery for

Internal Resistance of Square

The internal resistance of square - shaped lithium - ion batteries is a crucial parameter that significantly affects their performance. It consists of ohmic resistance and polarization resistance.

The difference between a square battery and a flexible pack battery

Jun 19, 2023 · The characteristics of flexible battery, flexible battery is a relatively new type of battery, it is very different from the square battery: The shape is more flexible, can be designed

What Determines LiFePO4 Battery Prices in the Philippines?

Mar 6, 2025 · LiFePO4 battery prices in the Philippines are shaped by multiple interconnected factors, including capacity, cell quality, brand reputation, import duties, BMS sophistication,

6 FAQs about [Are there square-shaped Manila lithium batteries ]

What is a square lithium battery?

Square lithium batteries are prismatic cells designed for high energy density applications, characterized by their rectangular shape that optimizes space utilization. What makes square lithium batteries safer than other types?

What is a lithium polymer battery?

Lithium polymer batteries are currently the least used battery form in electric vehicles. But in fact, we are not unfamiliar with it. Most of the batteries in mobile phones are lithium polymer batteries. The biggest difference between lithium polymer, cylindrical, and prismatic batteries is that their outer casing is made of aluminum-plastic film.

What are the different types of lithium battery packaging?

There are three main mainstream lithium battery packaging forms, namely cylindrical, prismatic, and lithium polymer. The three shapes of lithium batteries will eventually become cylindrical batteries, prismatic batteries and lithium polymer batteries through cylindrical winding, prismatic winding, and prismatic lamination.

What are the components of a square lithium battery?

Square lithium batteries consist of several key components: Top Cover: Protects internal components. Case: Typically made from aluminum or steel for durability. Positive Plate: Contains active material that facilitates energy storage. Negative Plate: Complements the positive plate in charge and discharge cycles.

What are the disadvantages of a square lithium battery?

Despite their advantages, square lithium batteries have notable drawbacks: Manufacturing Complexity: The variety of models complicates standardization and automation in production. Performance Variability: Differences among individual cells can lead to inconsistent performance in large packs.

What are the different types of lithium batteries?

The three shapes of lithium batteries will eventually become cylindrical batteries, prismatic batteries and lithium polymer batteries through cylindrical winding, prismatic winding, and prismatic lamination. Different packaging structures mean different characteristics, so what are their differences? Part 1. What’s the cylindrical lithium battery?

Learn More

- CRRC makes energy storage lithium batteries

- Can the base station power supply charge lithium batteries

- Assembly of four groups of three 12v lithium batteries

- Are Uruguayan lithium batteries safe

- Ghana bans lithium batteries for energy storage

- Selling lithium batteries for electric tools in Tajikistan

- Are lithium batteries safe in the Solomon Islands

- Is the 5g base station powered by lithium iron phosphate batteries

- Advantages and disadvantages of three-phase energy storage lithium batteries

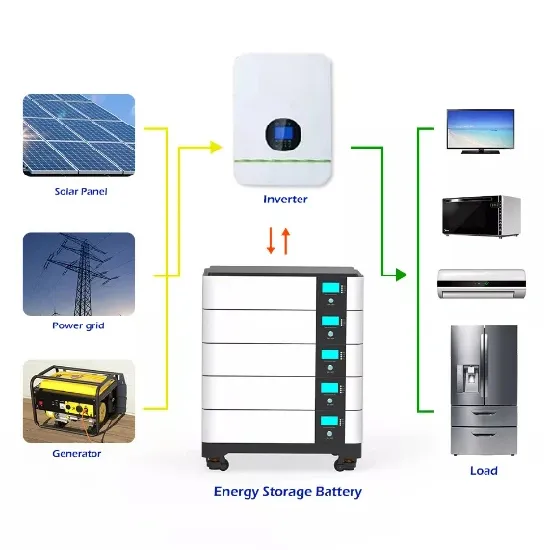

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.